RAMPF Machine Systems – Replication Technology Receives Top Accolade

RAMPF Machine Systems has won an Innovation Award of the WIF – Economic and Innovation Development Association Göppingen for its pioneering replication technology for mineral casting beds.

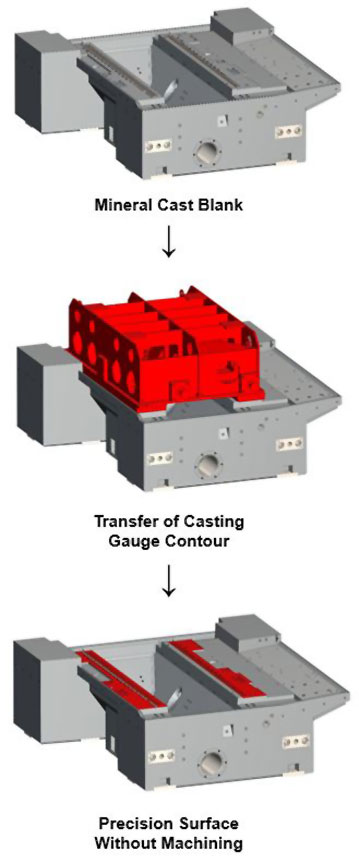

In order to achieve precise surfaces on machine beds made of mineral casting by means of mechanical processing, large milling centers or guideway grinding machines are usually required. The resulting high costs and lack of process reliability can now be circumvented – thanks to RAMPF Machine Systems' breakthrough molding technology.

With new materials as well as optimized manufacturing and processing methods, the numerous advantages of non-cutting machine beds made of mineral casting can now also be used for larger precision surfaces. Whereas replication accuracy in the hundredths of a millimeter range could previously be reliably achieved only with lengths up to 2.5 meters, RAMPF Machine Systems now achieves both flatness and straightness of 0.02 millimeters with a molding length of 4 meters.

A further advantage: the entire process is handled in-house, so customers of RAMPF Machine Systems are not dependent on external agents and avoid expensive transports.

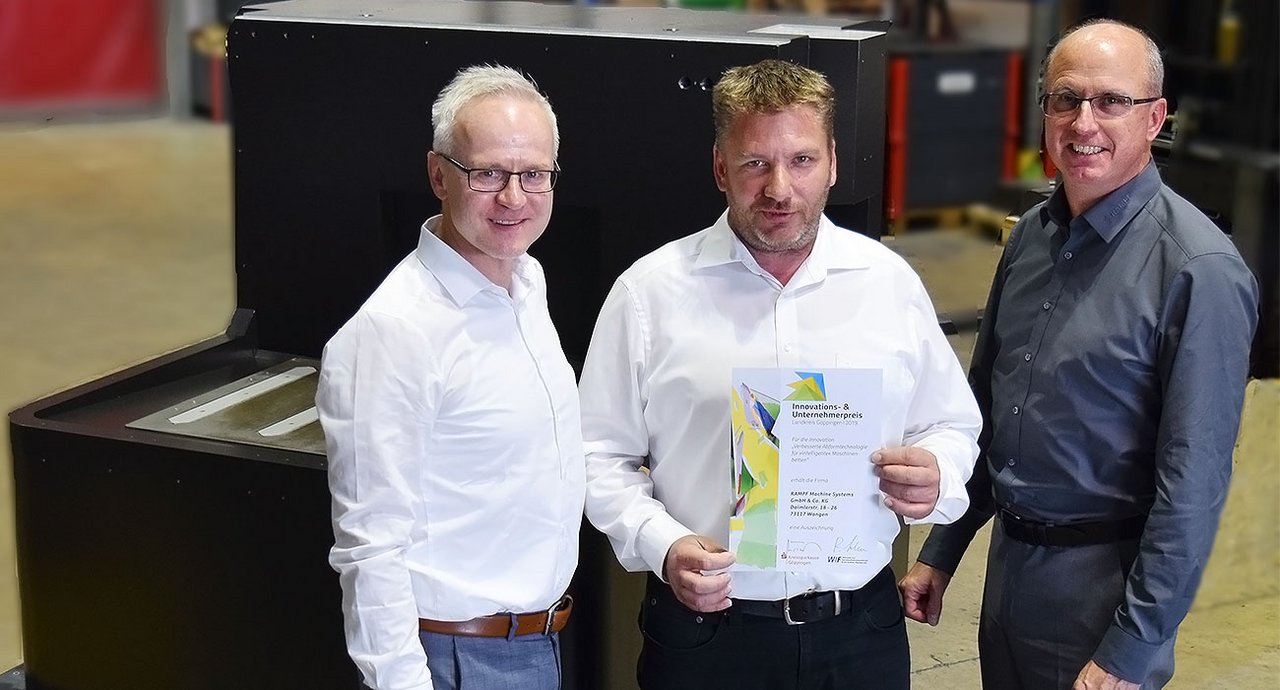

Thomas Altmann, CEO of RAMPF Machine Systems (left in picture together with co-CEO Dirk Haumann (right) and Marc Dizdarevic, Director of Technics/Development):

We are very proud of our technological milestone and this award. It reflects our commitment to never being satisfied with the status quo and working continuously on the development of new products and processes.

The WIF Innovation Award was presented for the 13th time this year. After 2001 and 2005, RAMPF Machine Systems has now won in this category three times. The WIF is a subsidiary of the district of Göppingen and is supported by grants from Kreissparkasse Göppingen, the district as well as towns and municipalities.