Stay Cool

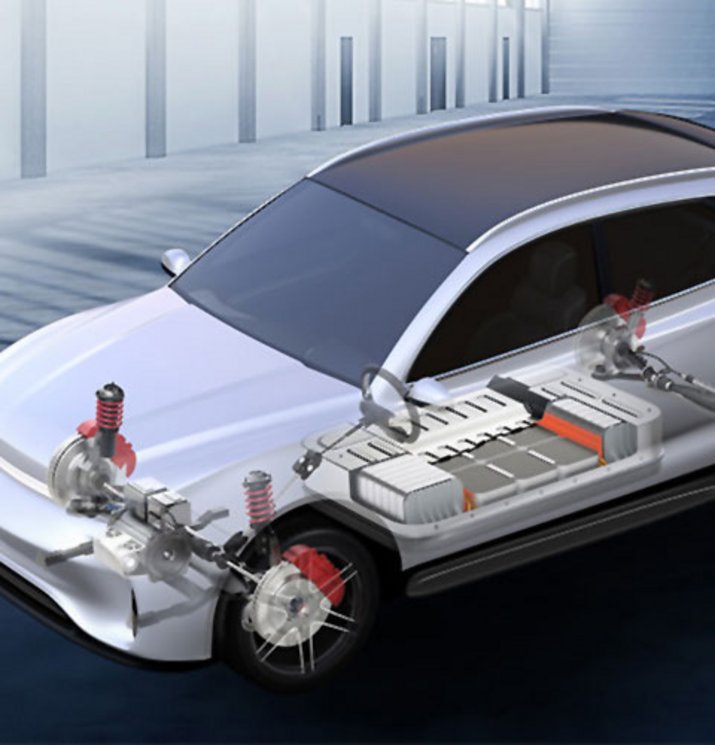

Electro casting resins are decisive in the further development of numerous industrial sectors. Whether in the automotive, electronics, energy or household industries, they are all heavily dependent on progress in the storage and transport of electrical energy.

The encapsulation of sensitive electronic components with electro casting resins from RAMPF Polymer Solutions protects them reliably and efficiently against chemical substances and environmental influences such as heat, cold and wetness - which increases performance. One requirement in particular is becoming increasingly important for electro casting resins: the thermal conductivity.

Increasing importance of thermal conductivity

In general, thermal conductivity is a measure of the material property of transporting thermal energy in the form of heat. The velocity with which heat flows through a material determines its thermal conductivity. We give the thermal conductivity in the unit W/m*K (watts per meter and Kelvin).

But why is the significance of thermal conductivity increasing?

There is one main reason for this: components of electronic components are becoming smaller and smaller. This is associated with an increase in power density. In order to guarantee efficient heat dissipation with low thermal load at the same time, a correspondingly high thermal conductivity of the electro casting resin is required.

Due to their outstanding thermal conductivity, resin systems from RAMPF Polymer Solutions ensure both the efficient dissipation of heat from the components and the maintenance of the required mechanical flexibility. This enables the reliable implementation of innovative solutions for power electronic components.

ERROR: Content Element with uid "47850" and type "textBesideImage" has no rendering definition!

The Product Portfolio of RAMPF Polymer Solutions

The product portfolio of RAMPF Polymer Solutions comprises electro casting resins based on polyurethane, epoxy, and silicone of the brands RAKU® PUR, RAKU® POX and RAKU® SIL.

RAKU® POX - Electro Casting Resins based on epoxy

- good impregnation behaviour

- high thermal conductivity

- low moisture sensitivity

- good flow properties (therefore suitable for complex components)

RAKU® POX – Elektrogießharze auf Basis von Epoxid

- gutes Imprägnierverhalten

- hohe Wärmeleitfähigkeit

- geringe Feuchtigkeitsempfindlichkeit

- gute Fließeigenschaften (dadurch für komplexe Bauteile geeignet)

RAKU® SIL - Electro casting resins based on silicone

- very good thermal shock resistance (especially suitable for flame retardancy)

- lasting flexibility

- good flow properties

- maximum protection against adverse environmental conditions, vibrations and temperature shocks

Fill in the contact form now and receive your free trade fair ticket!

RAMPF Polymer Solutions will once again present its expertise in the field of electro casting resins at productronica 2019 in Munich – Hall A3, Stand 241 – from November 12 - 15.

FILL OUT THE CONTACT FORM AND RECEIVE YOUR FREE TRADE FAIR TICKET FOR PRODUCTRONICA 2019!

WE LOOK FORWARD TO SEEING YOU!

Interesting articles

Mind the Gap

In power electronics and the battery industry, gap fillers ensure that sensitive electrical/electronic components do not overheat. The thermal pastes are thus also crucial for the success of electric mobility.