Mineral Casting – Exceptional Dynamics With Ultraprecision

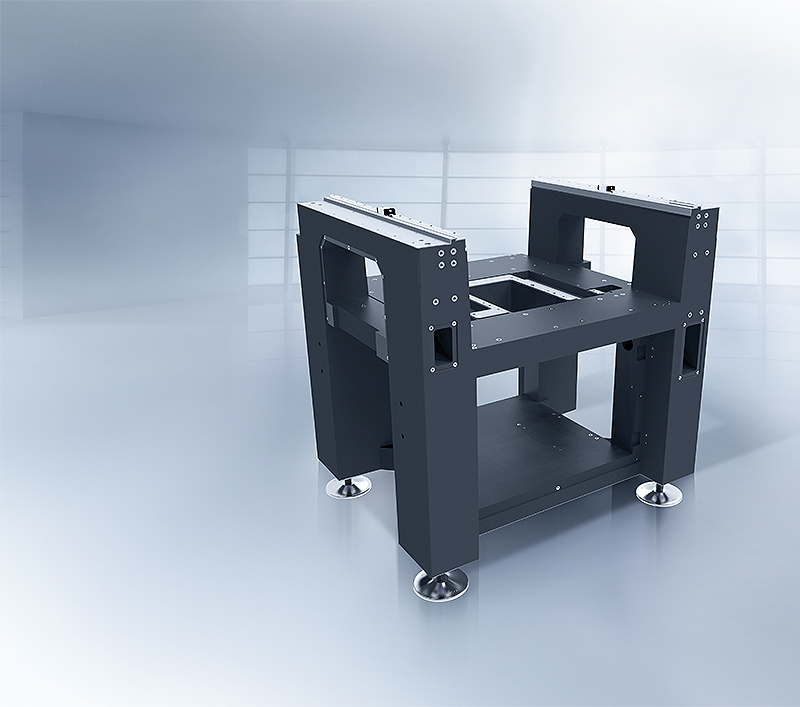

In electronics manufacturing and the microproduction sector, there is a demand for machines that are increasingly fast, precise, and, above all, cost-effective. This is exactly why more and more manufacturers are opting for EPUMENT®, the epoxy resin-bonded mineral casting from RAMPF Machine Systems, to build their machine beds and machine bed components.

Machines used for electronics manufacturing and microproduction need to produce increasingly powerful parts that are also becoming smaller and smaller – and they need to do so at top production speeds. This is only possible if the production machinery works with both exceptional dynamics and ultraprecision.

Mineral casting, with its almost unbeatable damping properties and outstanding levels of rigidity and temperature stability, offers exactly this combination of exceptional dynamics and ultraprecision.

Highly functional vibration-damping base

Semiconductor manufacture is a perfect application for mineral casting. For example, the high dynamics of a dispensing process – up to 40 soldering points per second – mean a highly functional yet vibration-damping base is vital.

Machine beds made of mineral casting from RAMPF are used throughout the process chain for producing electronic chips:

- Jet print technology, which has supplanted conventional screen printing throughout the world, needs to handle accelerations of up to 4G while also delivering total print accuracy.

- Wire and chip bonding calls for highly dynamic processes for manufacturing integrated circuits.

- Circuit board drilling machines need to provide outstanding drilling precision and maximum process reliability.

- Automatic pick-and-place machines for manufacturing circuit boards need to pick up, align, and place the tiniest of components with speed and precision.

Saving time and money

Another benefit of EPUMENT® mineral casting is that almost all functional elements that need to be integrated into a machine bed or machine bed component can be built into the mold before casting takes place. This cuts down the amount of finishing required, resulting in shorter delivery times.

In most cases, therefore, a finished machine bed does not mean that RAMPF Machine Systems’ work is at an end.

As Kacper Lasetzki, Sales Manager at RAMPF Machine Systems, explains:

Depending on the customer’s requirements, our experts carry on working. The aim is to save users time and money.

This is why the RAMPF production team uses ultraprecise molds at maximum production temperatures of 45 °C to manufacture components that offer an exceptional level of integration. This means the mineral casting blank already has a number of functions, such as:

- Routing for various lines (including hydraulic, pneumatic, compressed air, lubrication, and power lines) via cast piping systems.

- Shielding against radiation through use of radiation-absorbing EPURAM mineral casting for X-ray and inspection systems in medicine, industry, and research.

- Ultraprecise assembly and guide surfaces that can be applied to the mineral casting blank without cutting thanks to the pioneering RAMPF replication technology; they are also produced by means of grinding and the hand lapping process in the RAMPF precision grinding center.

However, this is far from all, as Holger Schmidt, Technical Sales Manager at RAMPF Machine Systems, explains:

In our role as development partner, we offer customers an end-to-end service – from the initial idea all the way to the finished machine. This service includes designing and assembling drive and positioning systems, complete with cable routing all the way to the control cabinet.

Outstanding vibration damping, excellent potential for integration, and environmentally-friendly manufacture and recycling all make EPUMENT® mineral casting the number 1 material for machine beds in traditional machine tool engineering applications and in the electronics, semiconductor, laser, medical, and packaging industries.

Interesting articles

Environmental Champion

The renowned F.A.Z-Institute recognizes RAMPF Group’s efforts to reduce waste and neutralize climate emissions.