Sealing systems for electromobility

Polyurethane, silicone, and epoxy resins for maximum safety, performance, and process stability.

RAMPF supplies customized sealing systems for battery trays, battery covers, electronic housings, and structural e‑mobility components.

Our materials are optimized for precise sealing and maximum durability — and can be fully automated using the appropriate dispensing technology.

Your benefit: reliable seals, stable processes, and maximum automotive performance.

Your Challenge :

Gaskets that have to deliver more than ever before

E‑mobility components are exposed to extreme conditions: major temperature fluctuations, mechanical stress, moisture, media exposure, and tight tolerances.

A gasket is not just a gasket— it’s a safety component, a lifetime determinant, and a key quality feature.

Our Solution:

Material systems developed for automotive sealing applications

Our polyurethane and silicone systems cover all relevant sealing requirements in electromobility — FIPFG, FIPG, liquid, foamed, or elastomer‑based.

Flexible, process‑stable, and long‑lasting — precisely tailored to your specifications.

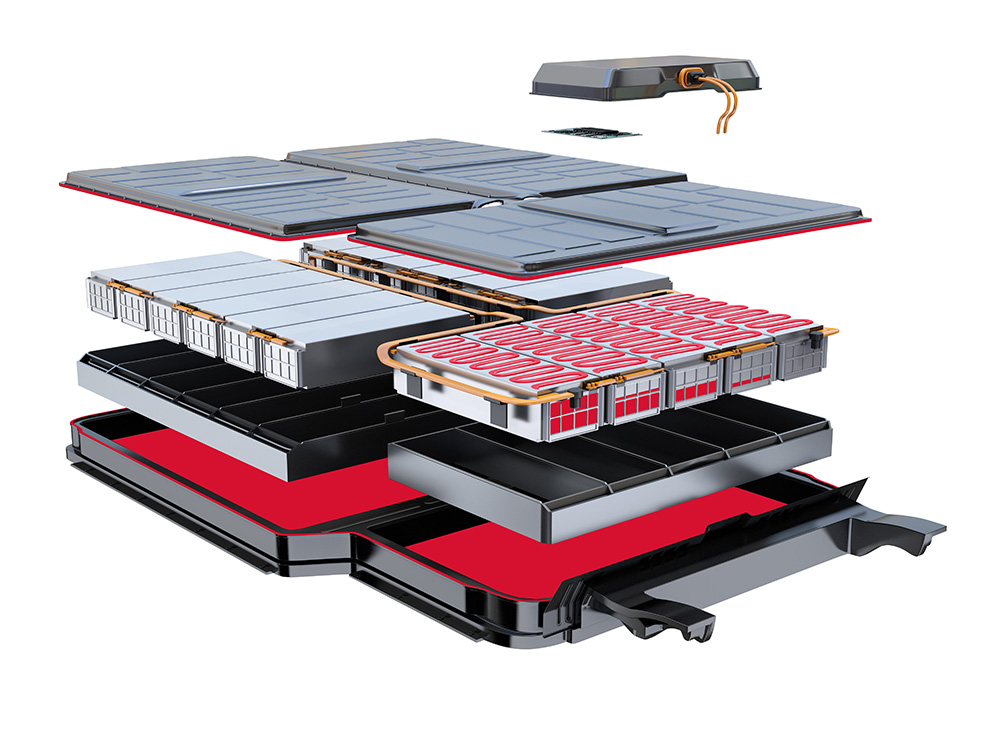

Casting or foaming battery cells

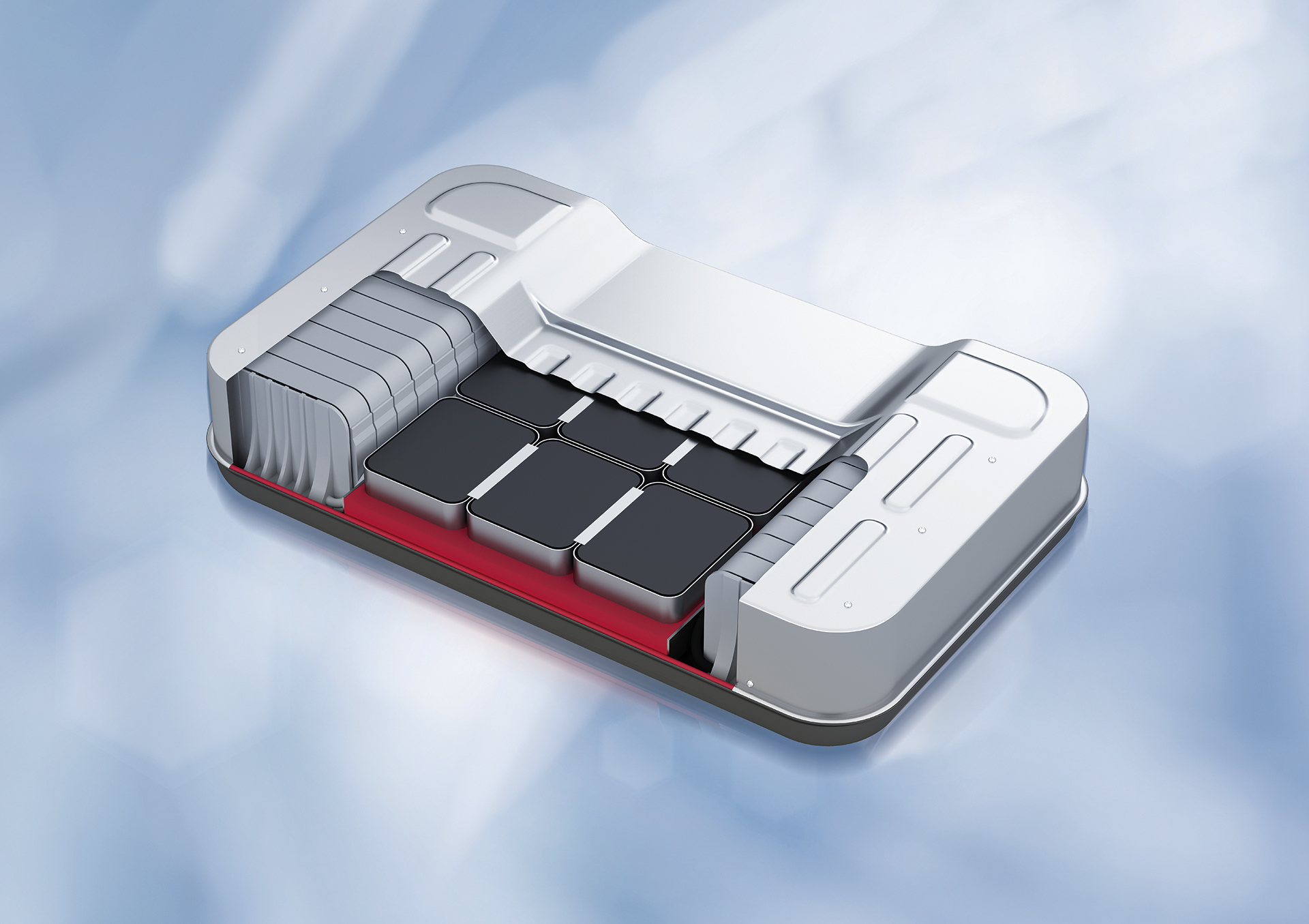

Sealing or bonding battery trays

Sealing or bonding battery covers

Ihre Vorteile auf einen Blick

Sealing the housing for wallbox and charging station

Sealing, casting, bonding and thermal-interface material of battery packs

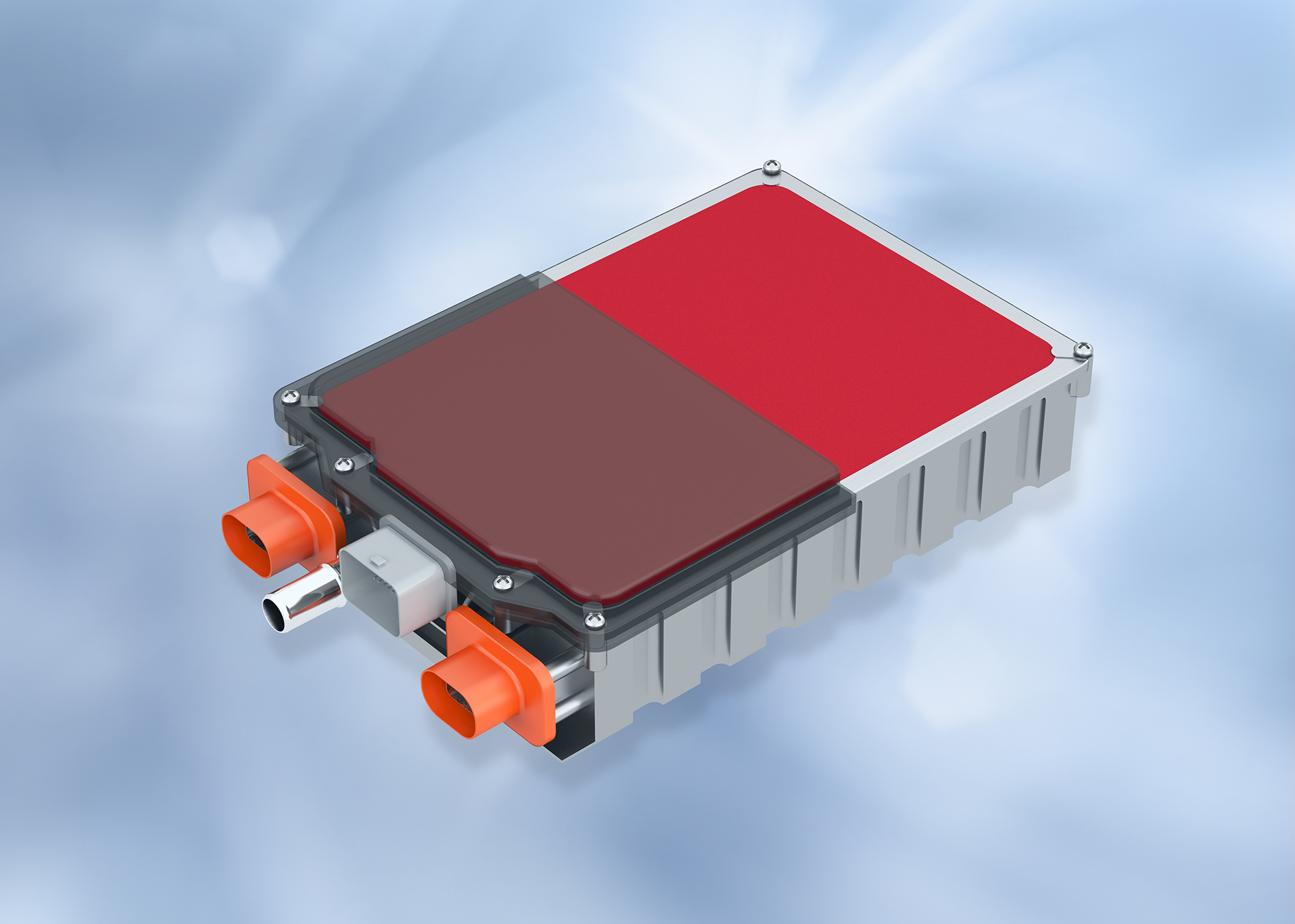

Sealing and casting of electronic control units and power electronics

Bonding and joining of car body components in the visible areas

Sealing, casting and thermal management of on-board chargers

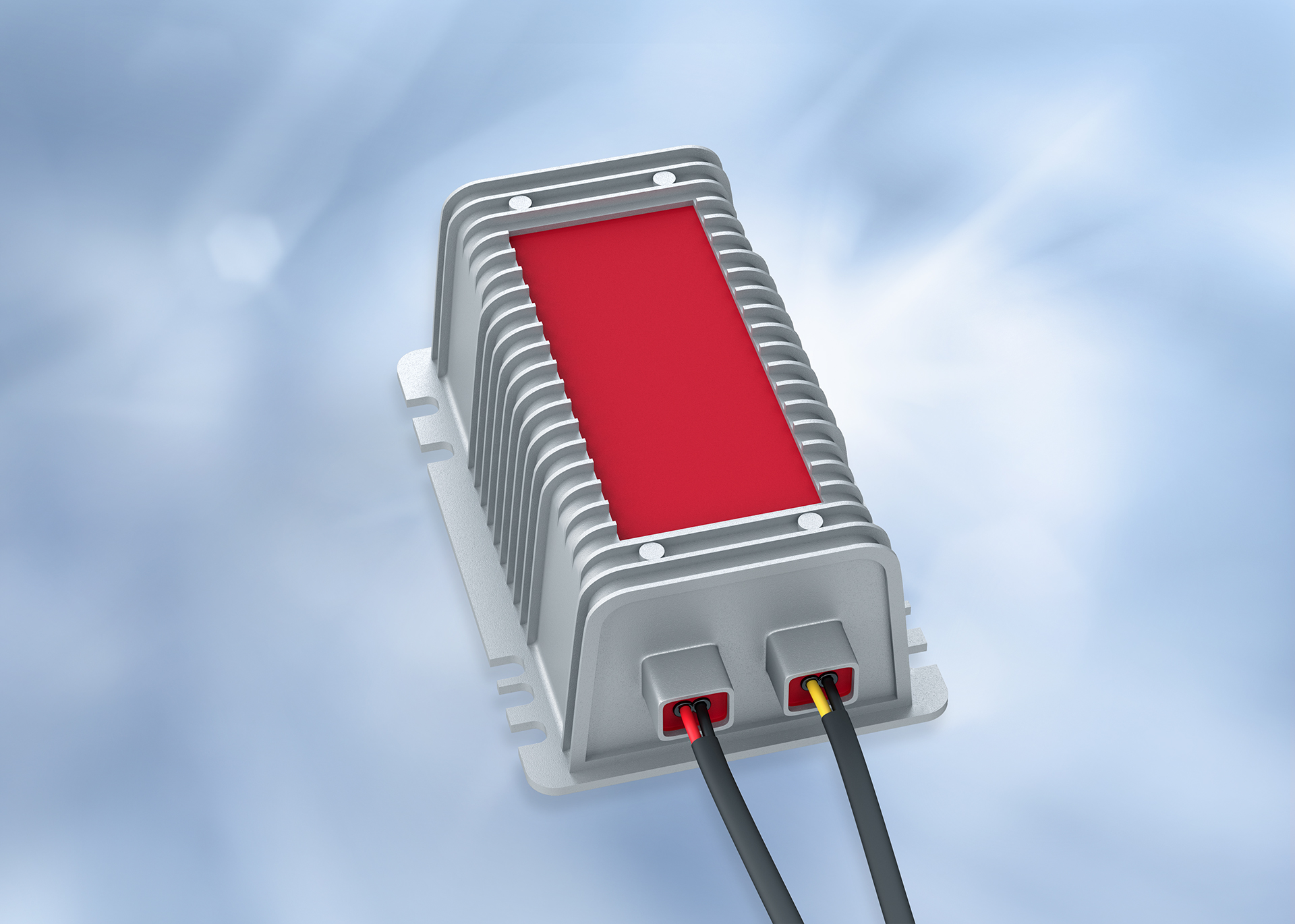

Sealing of housing of DC/DC converters

Technologie & Spezifikationen

Materialsysteme für Dichtanwendungen

- Polyurethan-Dichtungsschäume (PU)

Für FIPFG, weiche Schäume, gute Rückstellkraft - Silikon-Dichtungssysteme (SI) Für hohe Temperaturen, extreme Medien, langlebige Elastizität

- Epoxid-basierte Dichtmaterialien (EP) Für hohe chemische Beständigkeit & strukturelle Stabilität

Materialeigenschaften & Optionen

- Viskosität einstellbar: fließend bis hochthixotrop

- Reaktivität regulierbar für Taktzeiten & Prozessfenster

- Shore‑Härte variabel: weich, mittel, hart

- Farben individuell einstellbar

- Serienreife Standardprodukte + kundenspezifische Entwicklungsoptionen

Global Support. Anytime. Anywhere.