Driving Efficiency in China’s Automotive Design: RAMPF Starts Close Contour Casting Production in Nantong

The international RAMPF Group has officially launched Close Contour Casting production at its Nantong site. This advanced tooling technology delivers near-net-shape polyurethane preforms with unmatched speed, cost-efficiency, and sustainability – significantly accelerating automotive design development in China.

Key Takeaways

- RAMPF’s Chinese subsidiary has officially launched Close Contour Casting production at its Nantong facility.

- RAKU® TOOL Close Contour Castings are semi-finished polyurethane systems, supplied as three-dimensional preforms that are near the final shape of the produced part.

- Close Contour Casting technology actively supports sustainability goals by reducing energy consumption and minimizing production waste.

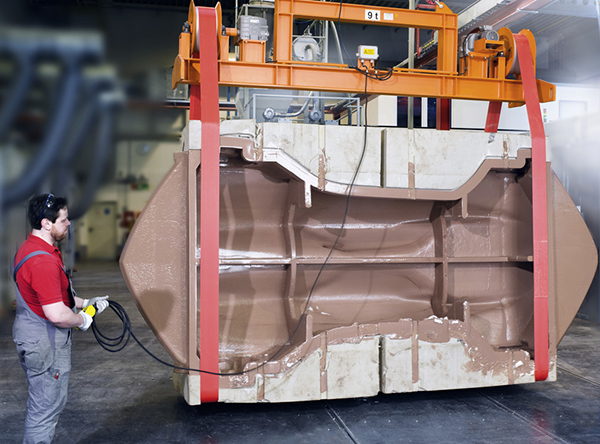

RAKU® TOOL Close Contour Castings are semi-finished polyurethane systems, supplied as three-dimensional preforms that are near the final shape of the produced part.

The manufacturing process begins with a lightweight mold – crafted from EPS or RAMPF’s RAKU® TOOL SB-0080 polyurethane styling board – based on data provided by the customer. After applying a release agent, the mold is filled using a specialized casting process. Post-curing and removal from the mold are followed by quick and easy milling.

Key benefits of RAMPF’s Close Contour Casting technology:

- Faster machining with reduced tool wear and material waste thanks to close-contour shape

- Minimal manual finishing due to a seamless, smooth, and dense surface (density 0.8 g/cm3)

- No handling of liquid chemicals – full focus on milling technology

- Excellent dimensional stability with low internal stress and isotropic properties comparable to board material

- Consistently high-quality standards for reliable performance

RAKU® TOOL Close Contour Casting systems are used to manufacture high-performance master models, cubing models, and data control models, amongst others.

Tiger Meng, CEO of RAMPF China:

Our local Close Contour manufacturing infrastructure cuts shipping times, reduces import costs, and enables faster market responsiveness. Most major global OEMs host design centers in Nantong, allowing them to directly benefit from RAMPF’s cutting-edge technology. What matters greatly to us and our customers: RAKU® TOOL Close Contour Casting actively supports sustainability goals by reducing energy consumption and minimizing production waste.

Denny Föhn, Director Business Center Tooling & Modeling at German-based RAMPF Advanced Polymers:

Customized blocks and advanced shell-casting structures enable faster, more cost-efficient solutions while ensuring superior product quality. We are excited that customers in China can now also leverage the benefits of RAMPF’s pioneering Close Contour Casting technology.