Driving E-Mobility in China with High-Performance Sealing, Casting, and Bonding Solutions

RAMPF (Nantong) Co., Ltd. is showcasing its comprehensive range of high-performance sealing systems, electro casting resins, gap fillers, and adhesives for battery packs and numerous other electric vehicle components at China International Battery Fair in Shenzen, May 15 to 17 – Hall 10/Booth T115.

Key Facts

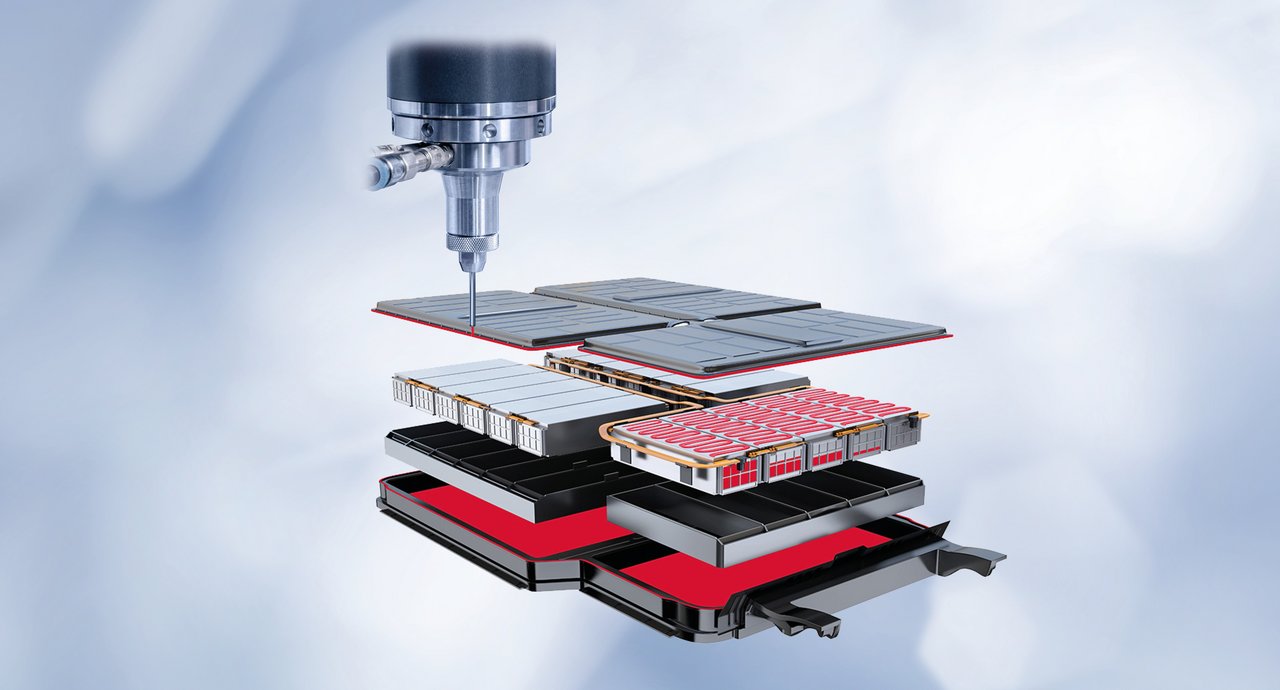

- RAMPF sealing foams deliver long-lasting protection against moisture, dust, and chemicals – ideal for battery packs and electric/electronic components.

- RAMPF electro casting resins and gap fillers ensure efficient thermal management and exceptional durability in demanding environments.

- RAMPF adhesive systems offer robust bonding combined with integrated functions such as sealing and thermal conductivity for enhanced performance.

China is the world’s largest electric mobility market and a key driver of global mobility innovation. The country leads in both production and sales of electric vehicles (EVs) and plug-in hybrids, with sales continuing to grow rapidly.

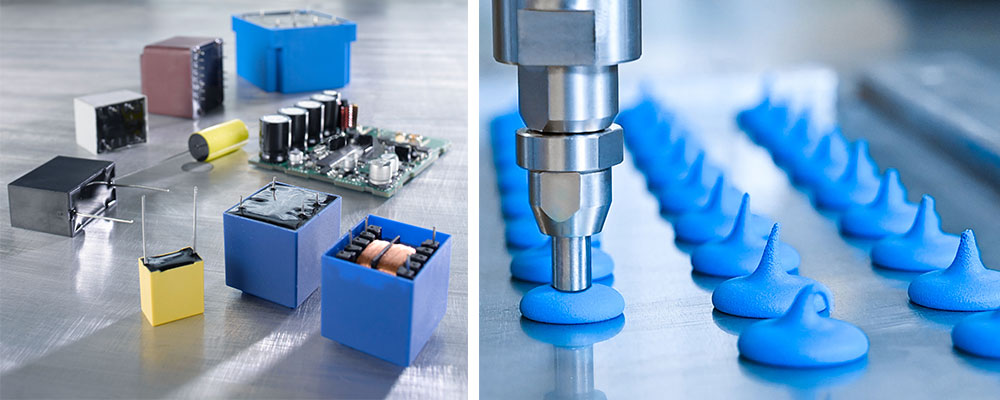

Since its founding in 2007, RAMPF (Nantong) – the Chinese subsidiary of the international RAMPF Group – has been contributing significantly to this dynamic development. The company specializes in high-performance reactive resin systems for sealing, casting, and bonding battery packs and numerous other components in electric vehicles, including sensors, power electronics, motors, stators, transformers, exterior parts, charging stations, charging plugs, and wall boxes.

Sealing Foams

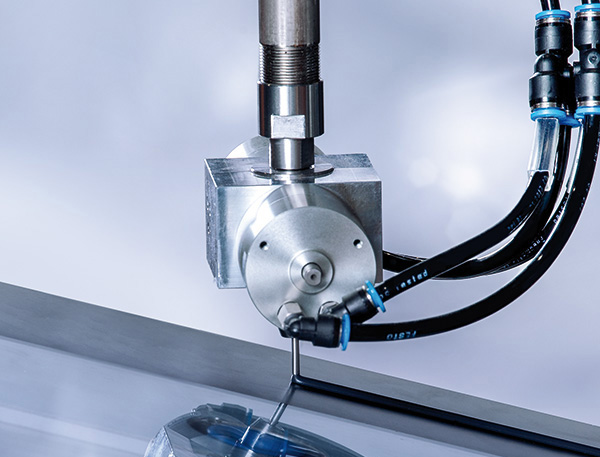

RAMPF offers liquid to highly thixotropic and compact gasket systems based on polyurethane (RAKU® PUR) and silicone (RAKU® SIL) that provide superior protection for battery housings, charging plugs, and charging stations against dust, dirt, moisture, chemicals, and harsh environmental influences. These advanced materials:

- Meet IP protection classes 67, 68, and 6K9K for exceptional impermeability

- Offer high flame retardancy (UL 94 up to V0) and rapid curing

- Are easy and fast to process with automated, high-speed dispensing systems

- Can be tailored in viscosity and Shore hardness

- Are approved by leading OEMs in the automotive and electronics industries

- RAMPF electro casting resins based on polyurethane, epoxy (RAKU® POX), and silicone ensure long-lasting protection of batteries and electronic components from temperature extremes, moisture, and chemical exposure.

- RAMPF gap fillers based on silicone offer outstanding thermal conductivity, high long-term tem-perature resistance and broad application range, excellent electrical insulation properties, low Shore hardness for flexibility, thixotropic behavior for high-speed, precise dispensing, as well as fast curing at room temperature, with optional heat acceleration.

Adhesive Systems

RAMPF polyurethane, epoxy, and silane-modified polymer adhesives provide strong, permanent bonding with excellent temperature and chemical resistance. Engineered for versatility and efficiency, these systems can be tailored to specific customer requirements and offer multifunctional performance by integrating sealing, thermal management, and structural integrity in one solution.

Patrick Yu, Head of Foam Business Center at RAMPF (Nantong):

We are committed to supporting China's electric mobility revolution with our innovative material technologies. RAMPF offers a high-quality standard portfolio of reactive resin systems for sealing, casting, and bonding, covering a wide range of chemical and mechanical properties. For special requirements, we rapidly deliver customized solutions – whether by adapting existing products or developing new systems quickly and cost-effectively.