Customized polymer solutions

for a sustainable future

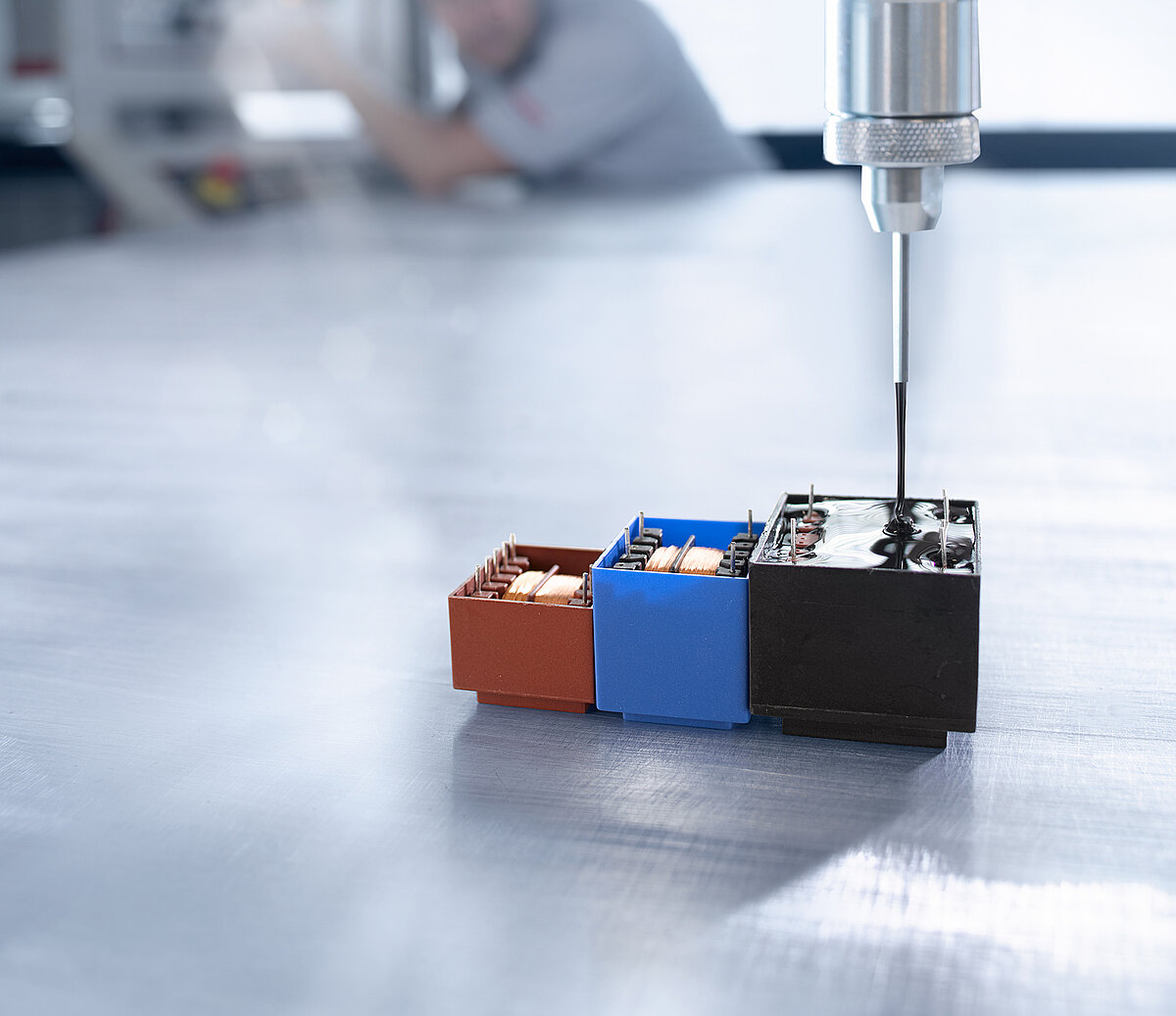

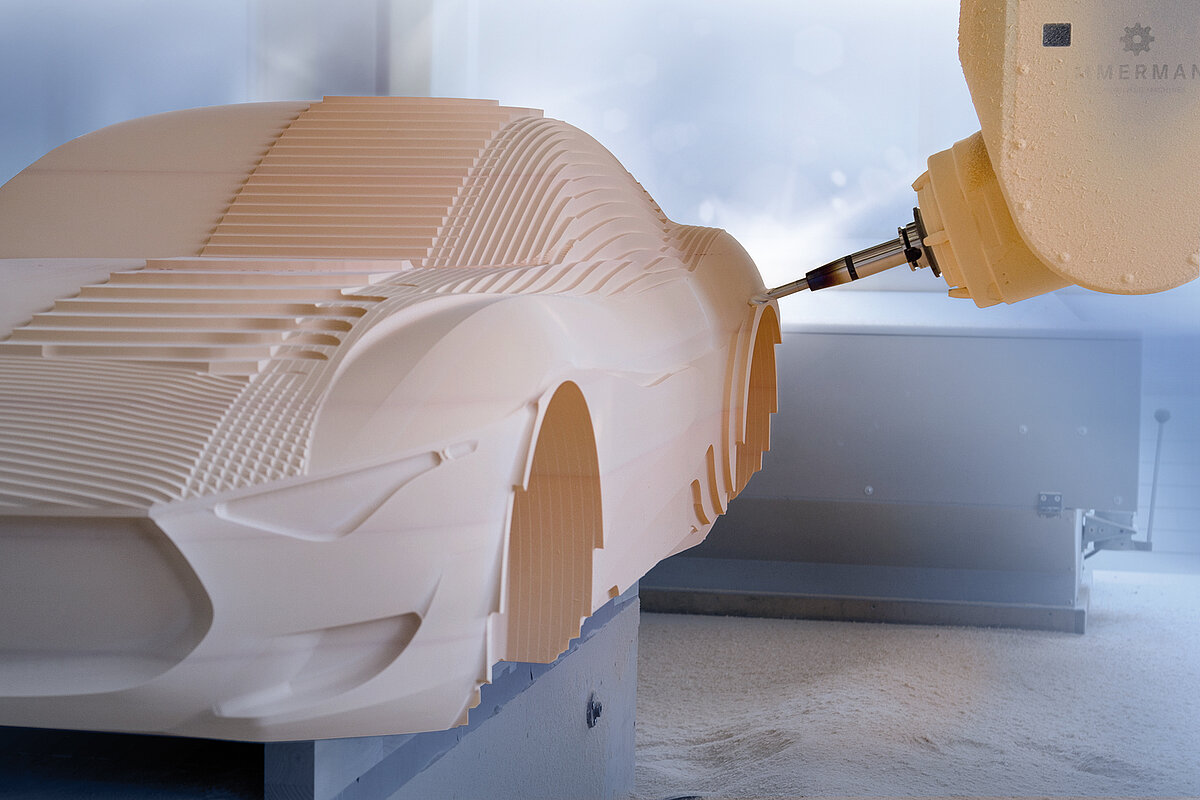

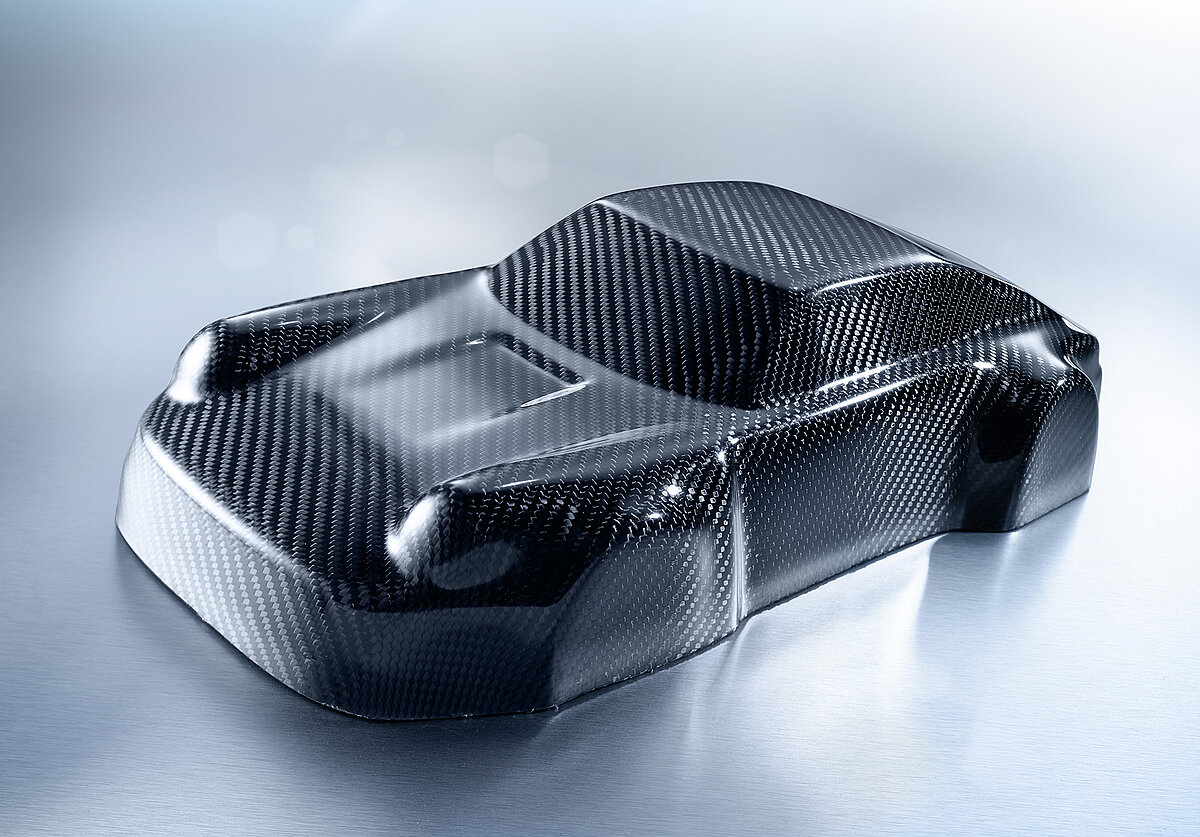

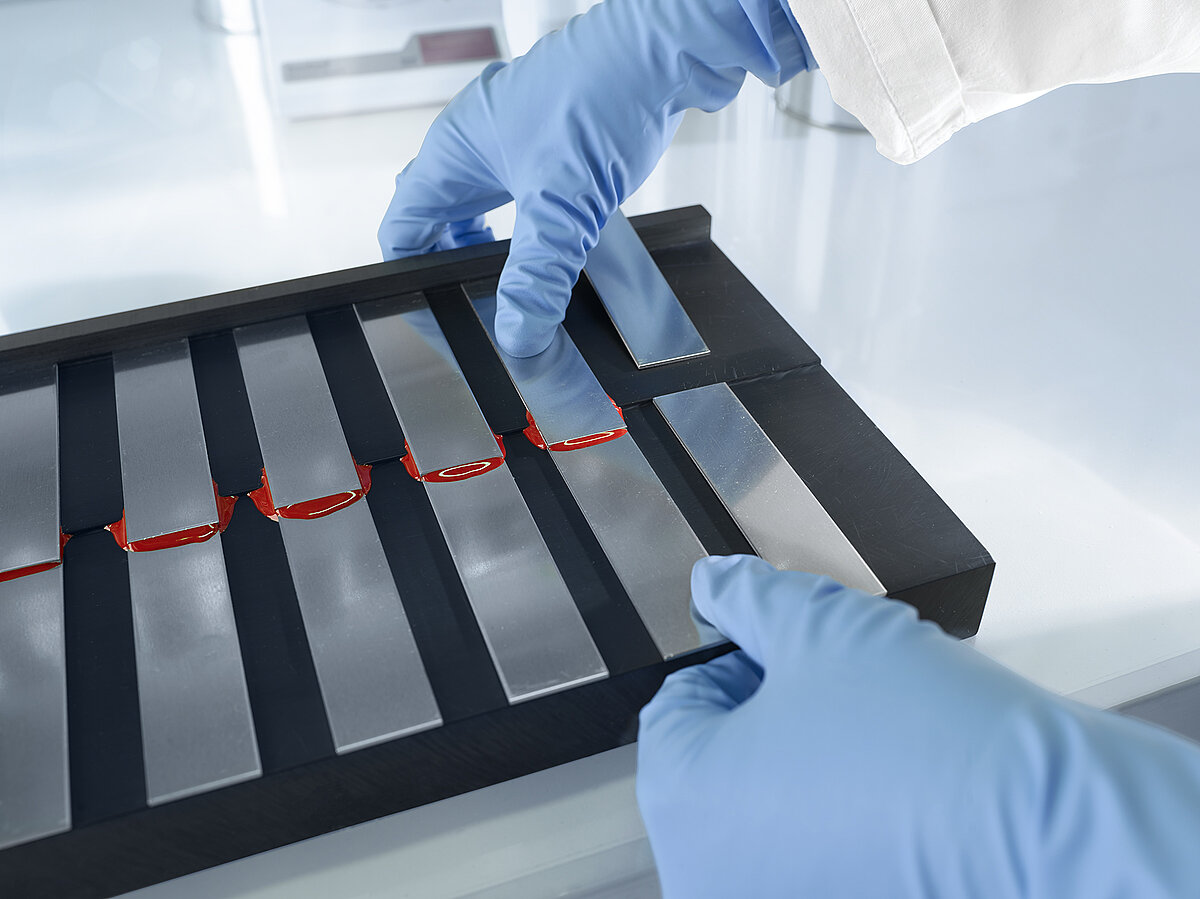

For more than 40 years, RAMPF Advanced Polymers has been developing reactive resin systems based on polyurethane, epoxy, silicone, and silane‑modified polymers. Our portfolio ranges from sealing and potting systems to materials for model and mold making, as well as sustainable recycling solutions. Around the world, we support numerous industries with high‑performance, resource‑efficient solutions — for today and tomorrow.

Inside view – the company movie

RAMPF Advanced Polymers is taking chemistry to a new level – sustainably and across the globe.

Laboratory and application technology

- Ultra-modern facilites on more than 1,000 m2

- Initial consultation on selecting the most suitable material and processing procedure

- Customized development of your material or adaptation of a product from our comprehensive portfolio

- Application engineering consultation for component design and manufacture of sample parts in near-series conditions

- Manufacture of prototypes

Processing expertise

- Support and consulting for applications as well as process development and optimization

- All-encompassing machinery pool for conducting near-series customer trials

- Mixing and dispensing systems from RAMPF Production Systems for processing one, two, and multi-component materials

After-sales service and training

- Our customer service does not end with the start of series production – technical field representatives, application technicians, and product developers are all at your service

- The RAMPF Academy offers product and application training courses that emphasize on sharing experiences

Know-how

- Customer- and progress-oriented approach – together with our customers we develop tomorrow’s solutions

- Expert and dedicated Key Technology Management team

- Comprehensive customer advice and cross-process expertise

- Material, plant, and process technology from a single source – RAMPF’s competent full-service offer

- Comprehensive expertise and many years of experience in processing technologies such as sealing, casting, bonding, foaming, coating, and design

Global Support. Anytime. Anywhere.