Lightweight Construction Meets Regional Strength: RAMPF and Vöhringer Redefine Industry Standards

Autumn has arrived – the days grow shorter, the evenings cooler. Yet a touch of wanderlust lingers. We recall sunlit drives heading south and tranquil hours on the water – moments from a summer that quietly slipped away. While motorhomes and yachts begin their winter rest, one thing remains unchanged: the passion for innovation and lightweight construction. A recent collaboration between Vöhringer GmbH & Co. KG from Trochtelfingen and the RAMPF Group exemplifies how two regionally rooted, family-run companies are redefining the production of lightweight components through shared expertise and cutting-edge technology.

Tailor-Made Technology for Precision Lightweight Construction

Since the beginning of the year, Vöhringer – a specialist in furniture and interior fittings for caravans and yachts – has been using an integrated solution from RAMPF that combines a customized polyurethane system with an automated production plant.

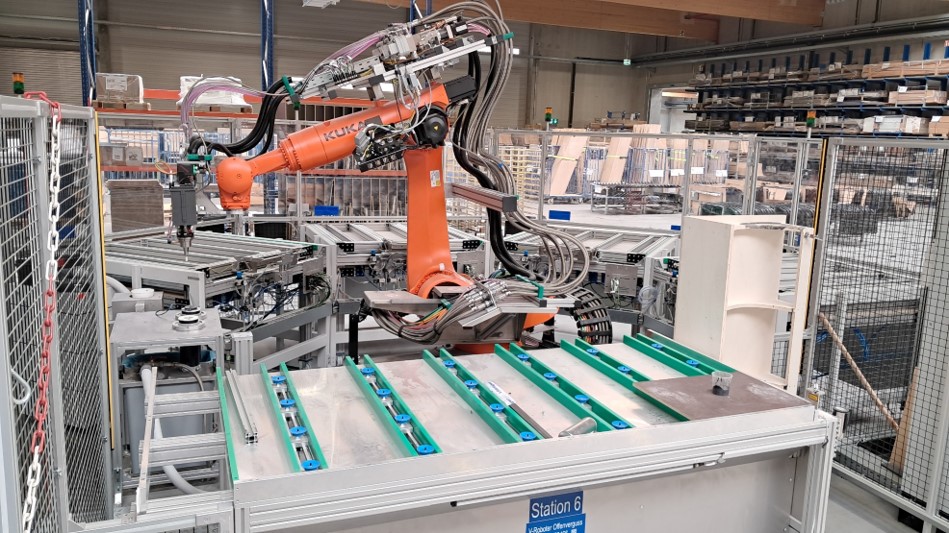

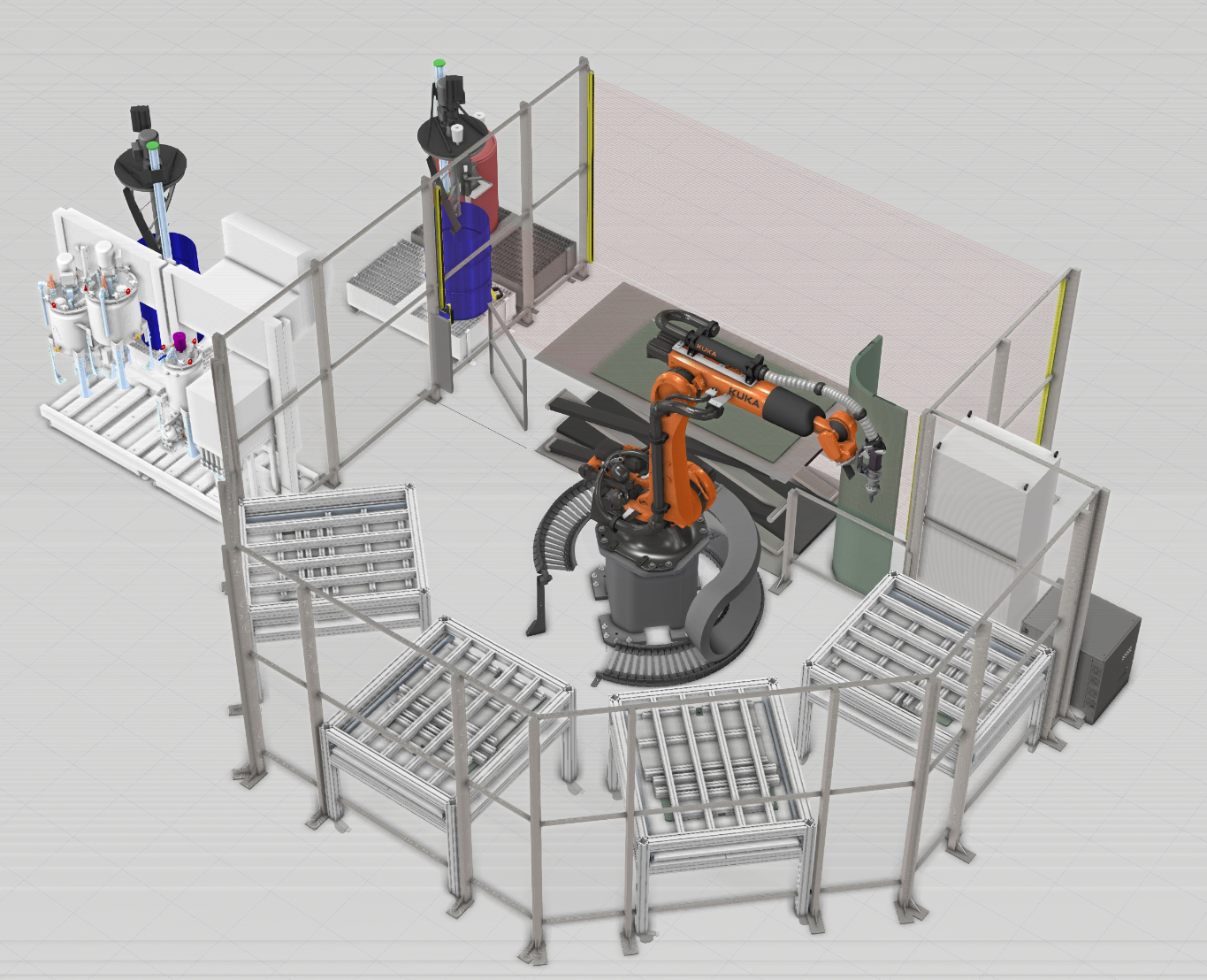

At the heart of the process is the polyurethane system RAKU® PUR 70-4711, used in two color variants and processed on a C-DS+R system featuring KUKA robot integration. This setup enables precise edge casting in sandwich construction, delivering high strength with minimal weight.

The project was realized through close collaboration between RAMPF Advanced Polymers and RAMPF Production Systems, under the leadership of Project Manager Tilmann Bippus. The automated solution ensures consistent product quality and efficient production processes – essential in a market that demands lightweight design, aesthetics, and durability.

Tilmann Bippus, Project Manager at RAMPF Production Systems:

From the outset, this joint project was defined by mutual trust and technical ambition. The core challenge was to merge model-making expertise with highly automated dispensing technology for casting model construction panels. Proven components from model making were integrated into the automated concept, which also required further development. To enable flexible production, multiple manufacturing modes were implemented, and a camera system was introduced and optimized to reach its full potential. With goal-oriented problem-solving and a foundation of trust, everything simply works better. High-tech and pragmatism aren’t contradictions – they complement each other.

Flexibility Meets Precision – Every Component a Unique Piece

The system is used in the interior construction of motorhomes and yachts and has been precisely tailored to meet Vöhringer’s specific requirements.

Because each piece of furniture is unique, production demands both exceptional flexibility and precision. The newly implemented machine is therefore variably programmable and individually adjustable to accommodate a wide range of geometries and designs.

Beyond supplying the material solution, RAMPF also handled the complete programming of the system. An integrated camera recognition system ensures automatic identification and accurate processing of each component.

Knowledge Transfer Through Hands-On Training

To fully leverage the new technology, Vöhringer became the first company to complete an in-house training program at RAMPF for operating the KUKA robot.

Over a two-week period, three employees from Trochtelfingen underwent hands-on training under the guidance of Marc Stegmüller, Robotics Expert at RAMPF Production Systems.

This practical training laid a solid foundation for the safe, efficient, and independent operation of the new system, empowering Vöhringer to maximize performance and maintain high production standards.

Regional Partnership as a Catalyst for Success

What makes this partnership truly special is not just the technical implementation, but also the regional proximity.

Both Vöhringer and RAMPF are family-owned, medium-sized enterprises with deep roots in the Swabian Alb region. This shared local identity fosters a strong sense of collaboration and trust.

Personal connections, such as those established through the Reutlingen Chamber of Industry and Commerce (IHK), further supported the project, enabling short communication channels and agile decision-making.

Experience, Quality – And a Vision for the Future

Founded in 1921, Vöhringer is now one of the leading suppliers of lightweight components for motorhomes, yachts, and interior fittings, specializing in surface coating, furniture production, profiles, PU molded parts, and innovative lightweight solutions.

By combining material expertise and system technology, the company consistently manufactures products of the highest quality – efficient, precise, and forward-looking.

Raven Vöhringer, Managing Director of Vöhringer GmbH & Co. KG:

The successful implementation of this specialized machine, with all its complex requirements, demonstrates how satisfied we are with the collaboration. It confirms that regional partnerships provide the perfect foundation for innovative solutions.

Innovation That Endures

This joint project showcases the innovative strength of medium-sized enterprises: practical, solution-driven, and rooted in partnership. And while summer may be over, the drive for progress and fresh ideas continues – season after season.