Sealing Systems for Electric Mobility

Polyurethane, Silicone, and Epoxy Resins for Maximum Safety, Performance, and Process Stability.

RAMPF supplies customized sealing systems for battery trays, battery covers, electronic housings, and structural e‑mobility components.

Our materials are optimized for precise sealing and maximum durability — and can be fully automated using advanced dispensing technology.

Your Key Benefit: reliable seals, stable processes, and maximum automotive performance.

Your Challenge:

Gaskets that have to deliver more than ever before.

E‑mobility components are exposed to extreme conditions: major temperature fluctuations, mechanical stress, moisture, media exposure, and tight tolerances.

A gasket is more than a sealing element – it is a safety‑critical component that defines service life and ensures consistent quality.

Our Solution:

Material systems specially developed for automotive sealing applications.

Our polyurethane and silicone systems cover all relevant sealing requirements in electro mobility - FIPFG, FIPG, liquid, foamed, or elastomer‑based.

Flexible, process‑stable, and long‑lasting - precisely tailored to your specifications.

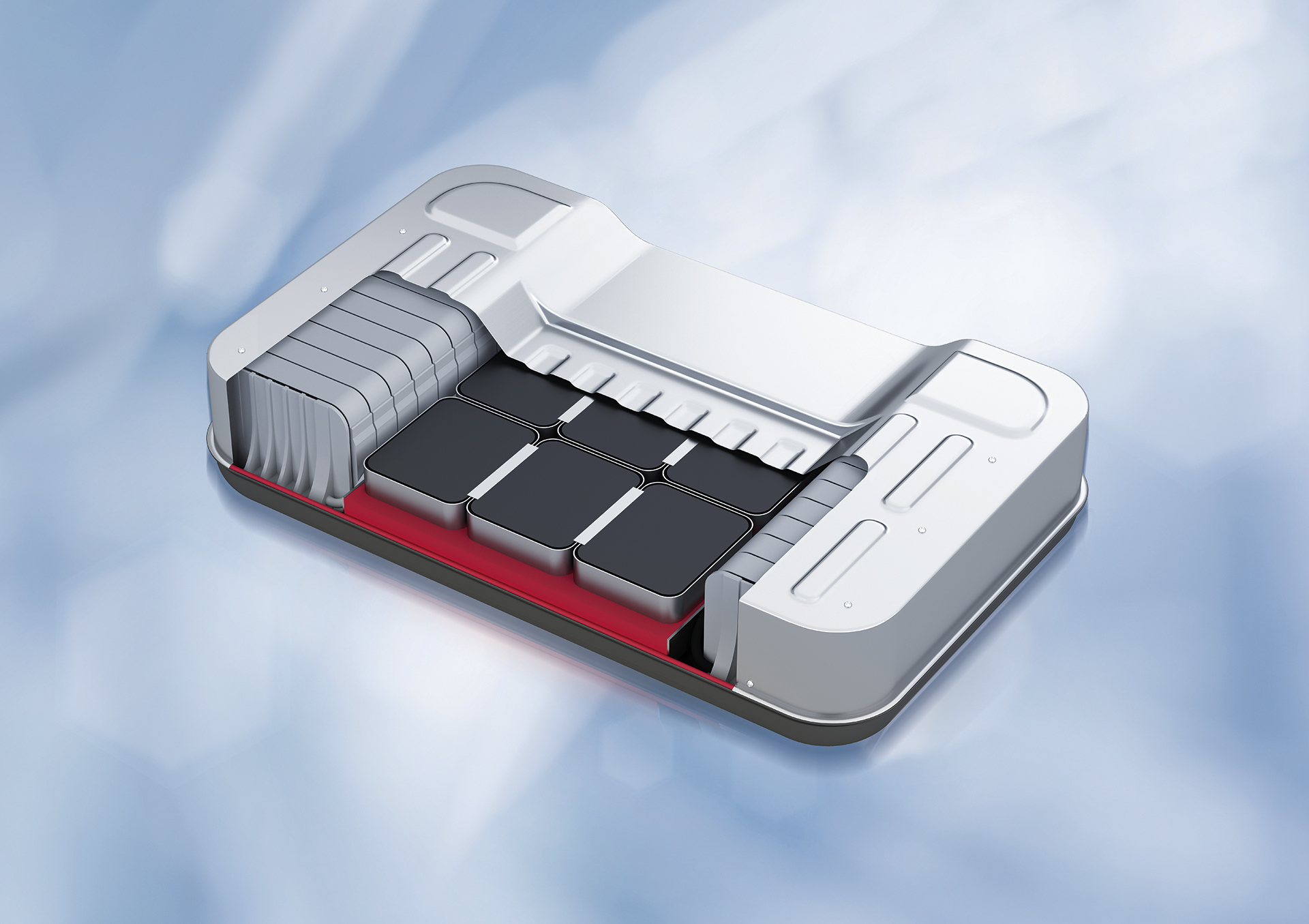

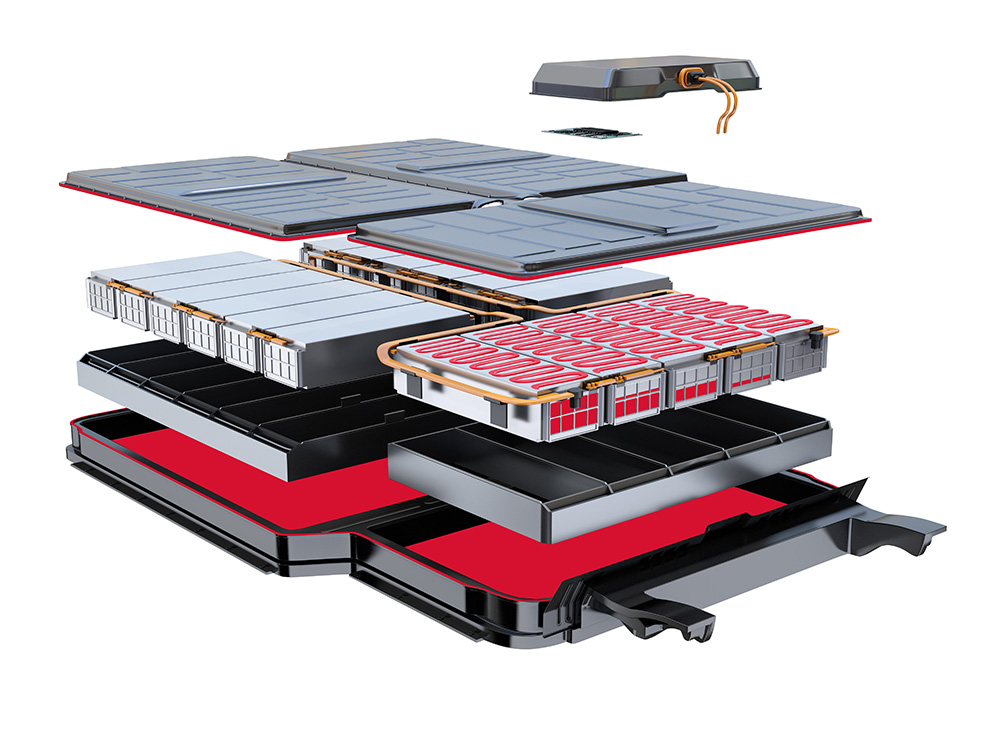

Casting or foaming battery cells

Sealing or bonding battery trays

Sealing or bonding battery covers

Ihre Vorteile auf einen Blick

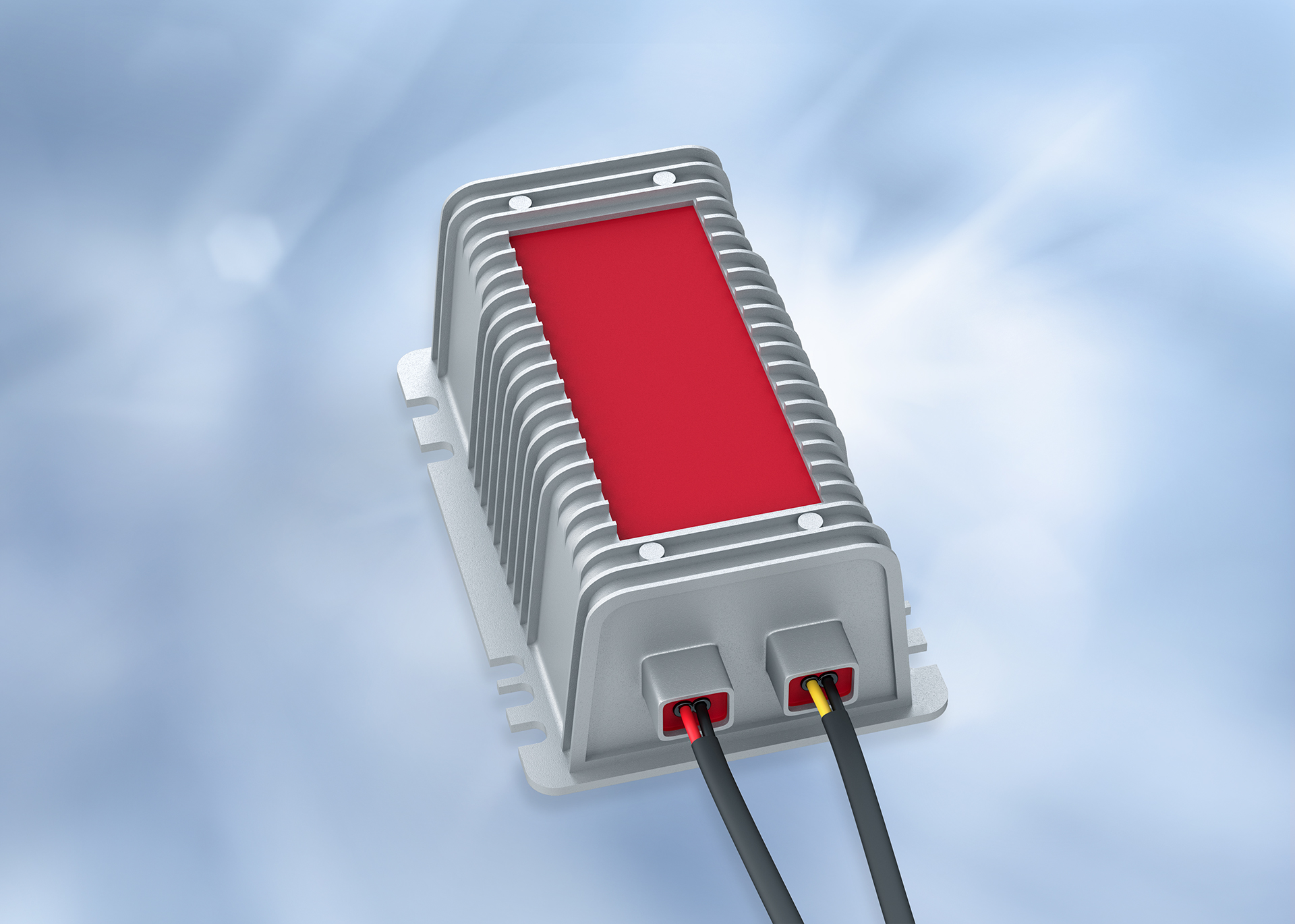

Sealing the housing for wallbox and charging station

Sealing, casting, bonding, and thermal-interface material

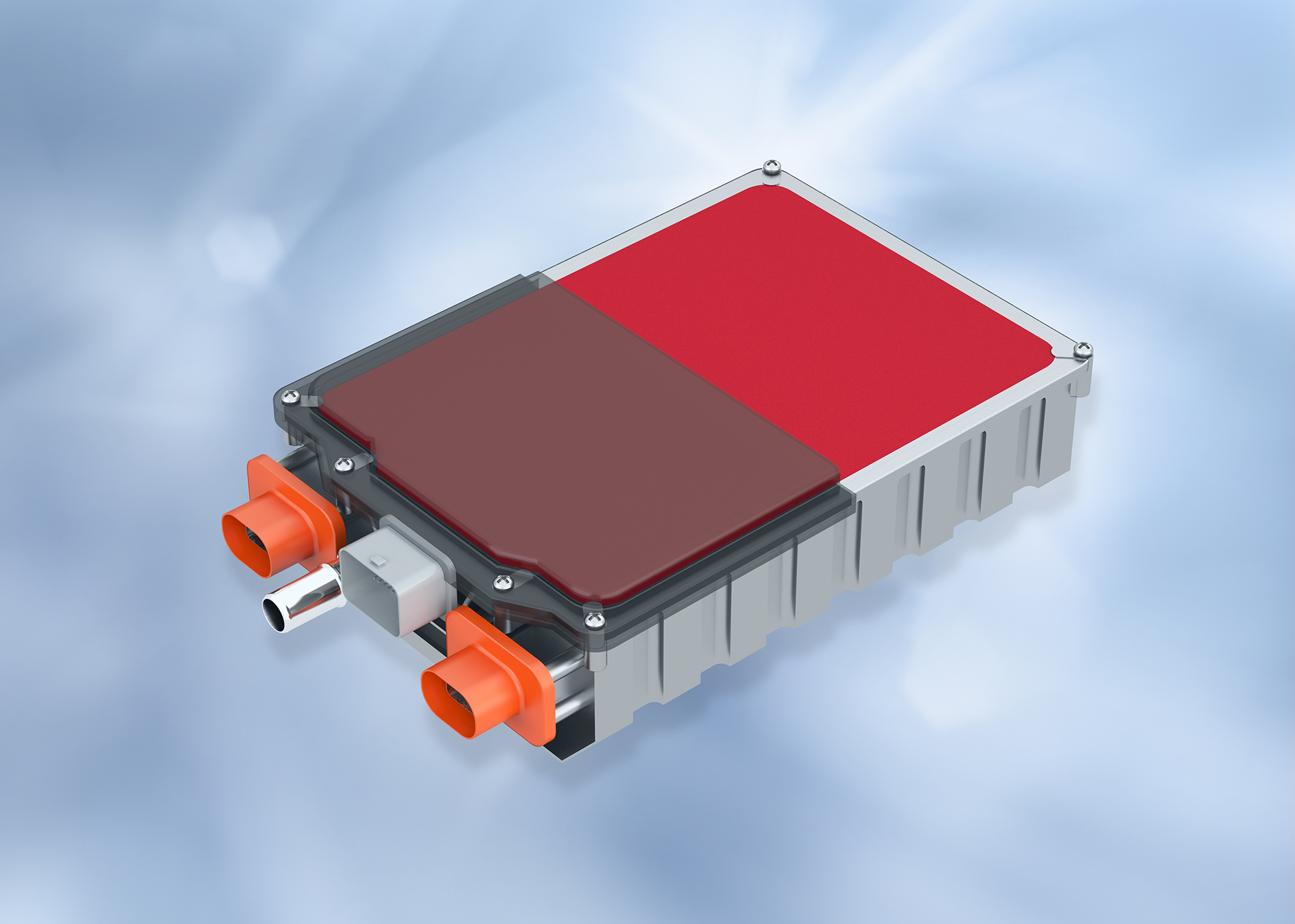

Sealing and casting of electronic control units and power electronics

Bonding and joining of car body components

Sealing, casting, and thermal management

Sealing of DC/DC converters housing

Technology and Specifications

Material systems for sealing applications

Polyurethane sealing foams (PU)

for FIPFG, soft foams, good rebound/resilience properties

Silicone sealing systems (SI)

for high temperatures, extreme media, long-lasting elasticity

Epoxy-based sealing materials (EP)

for high chemical resistance and structural stability

Material properties and options

- Adjustable viscosity: from free‑flowing to highly thixotropic

- Regulatable reactivity: for cycle times and process windows

- Variable Shore hardness: soft, medium, hard

- Customizable colors

- Series‑ready standard products + customer‑specific development options

Certifications and Experience

- IATF 16949 – for automotive series production processes

- ISO 9001 – certified quality assurance

- Global application engineering & laboratories

- Series‑relevant testing & sample production for SOP acceleration

- Testing of recyclates & bio‑based raw materials

- Approved by leading OEMs & Tier‑1 suppliers

Global Support. Anytime. Anywhere.