Board Materials

for Styling, Model Making and Tooling – Mill it. Done.

For over 40 years, we have been developing innovative Board Materials for model making, mold making and tooling – engineered in Germany. Our RAKU® TOOL solutions deliver efficiency, performance, and sustainability: densities from 0.08–1.7 g/cm³, fine surface quality, high dimensional stability, easy machining, plus perfectly matched adhesives and repair fillers. Through closed-loop recycling, we reuse up to 50 percent of production residues; our systems contain up to 30 percent chemically recycled components. Tooling and Modeling – efficient, powerful, sustainable.

Properties and Functions

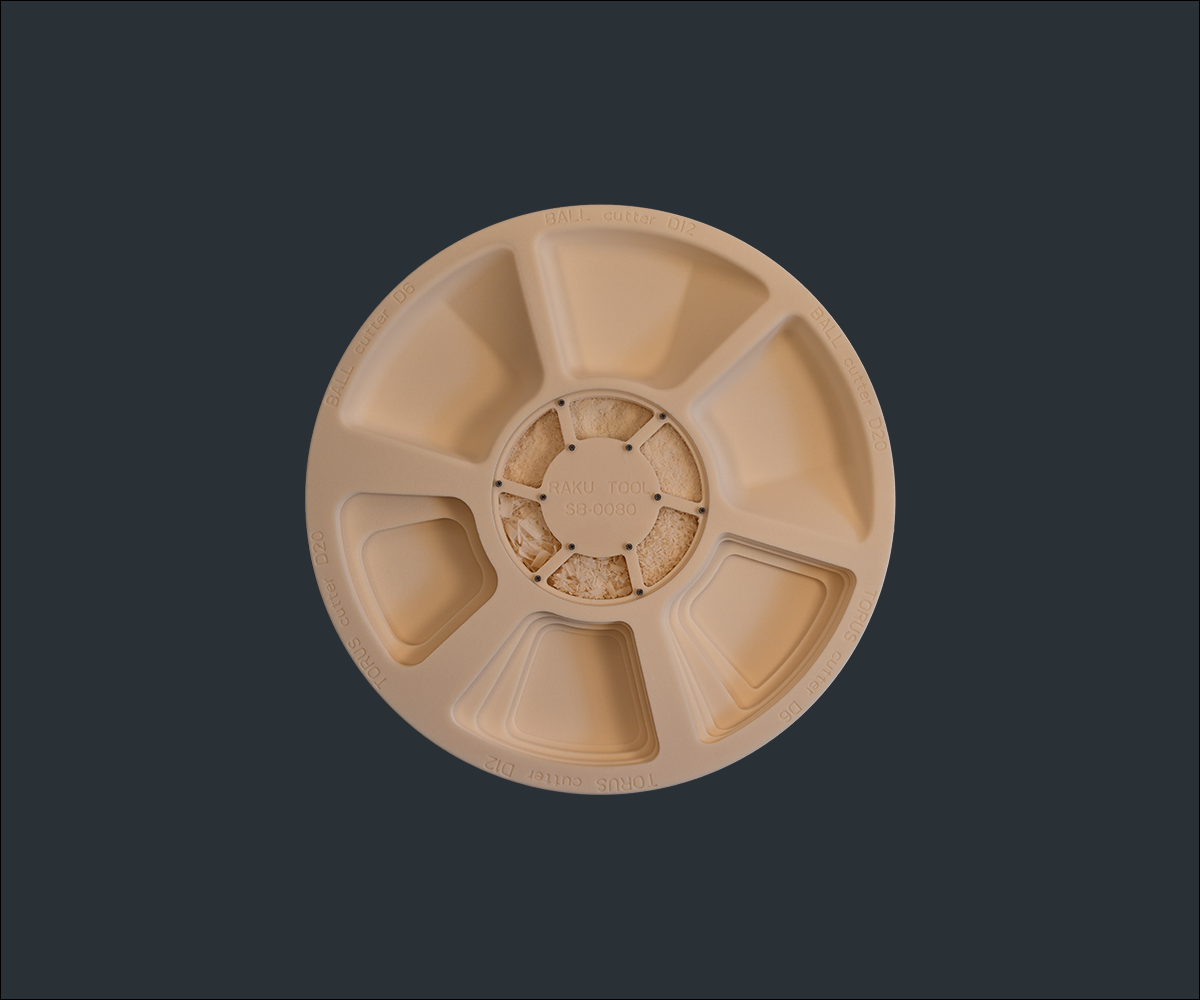

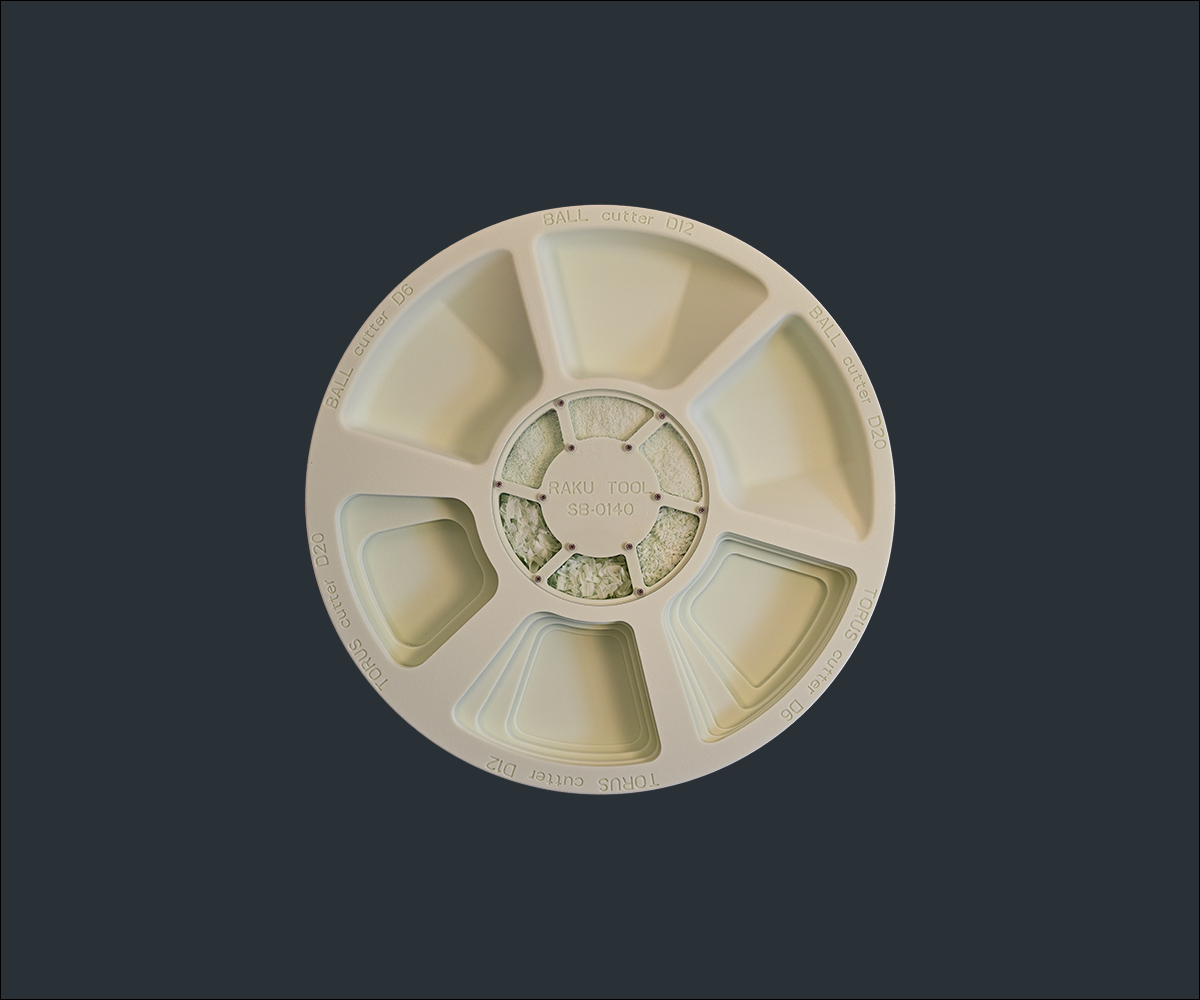

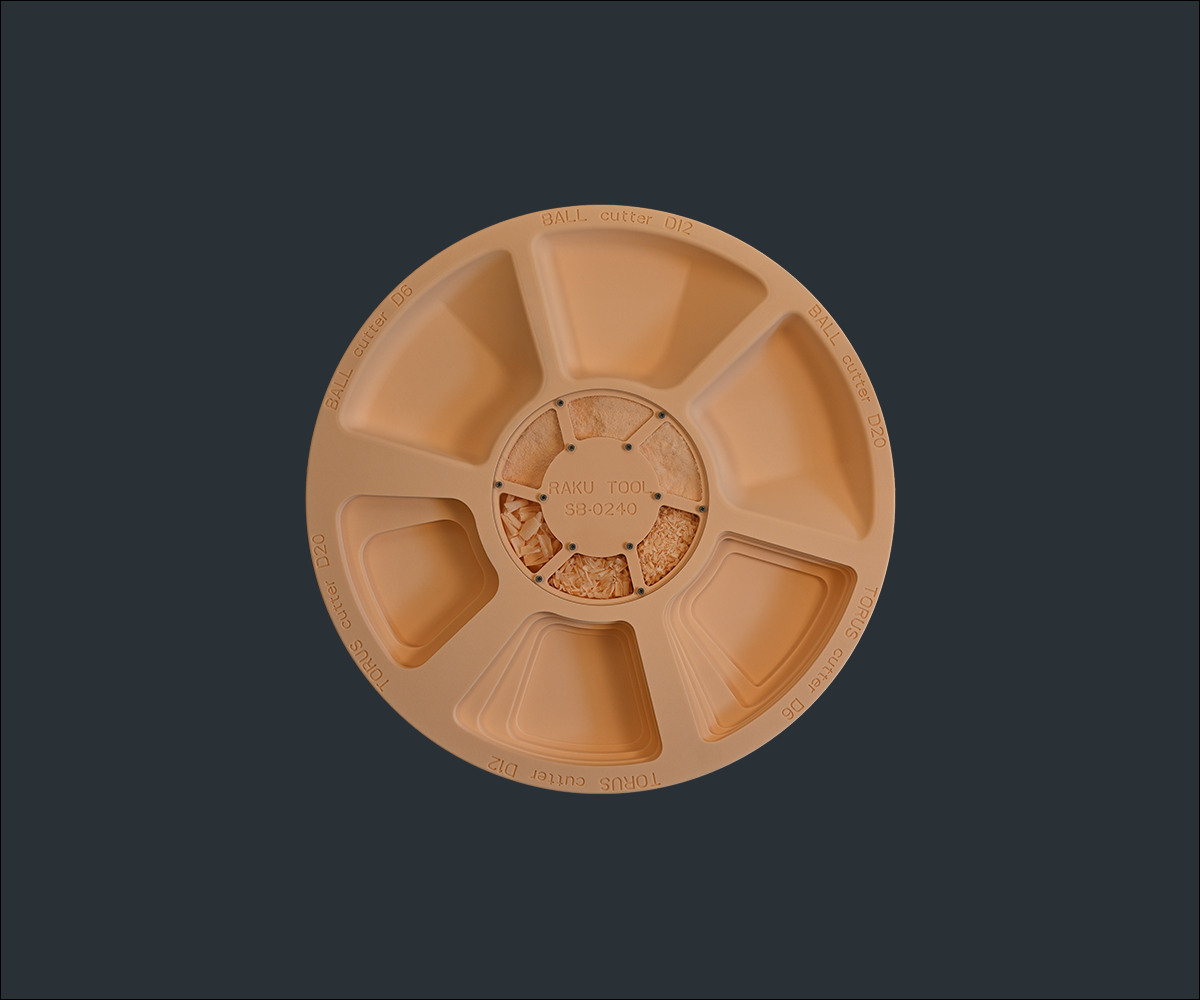

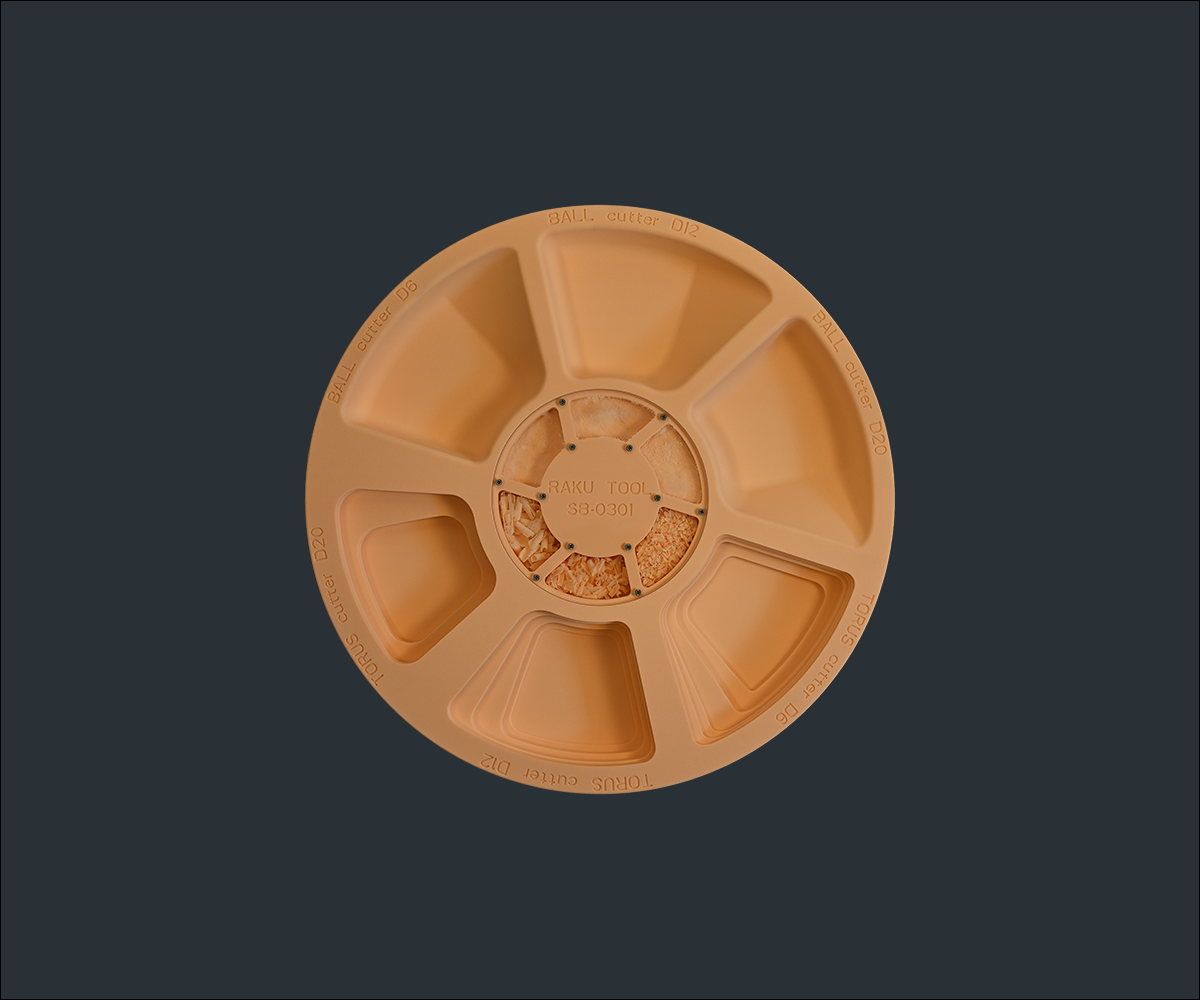

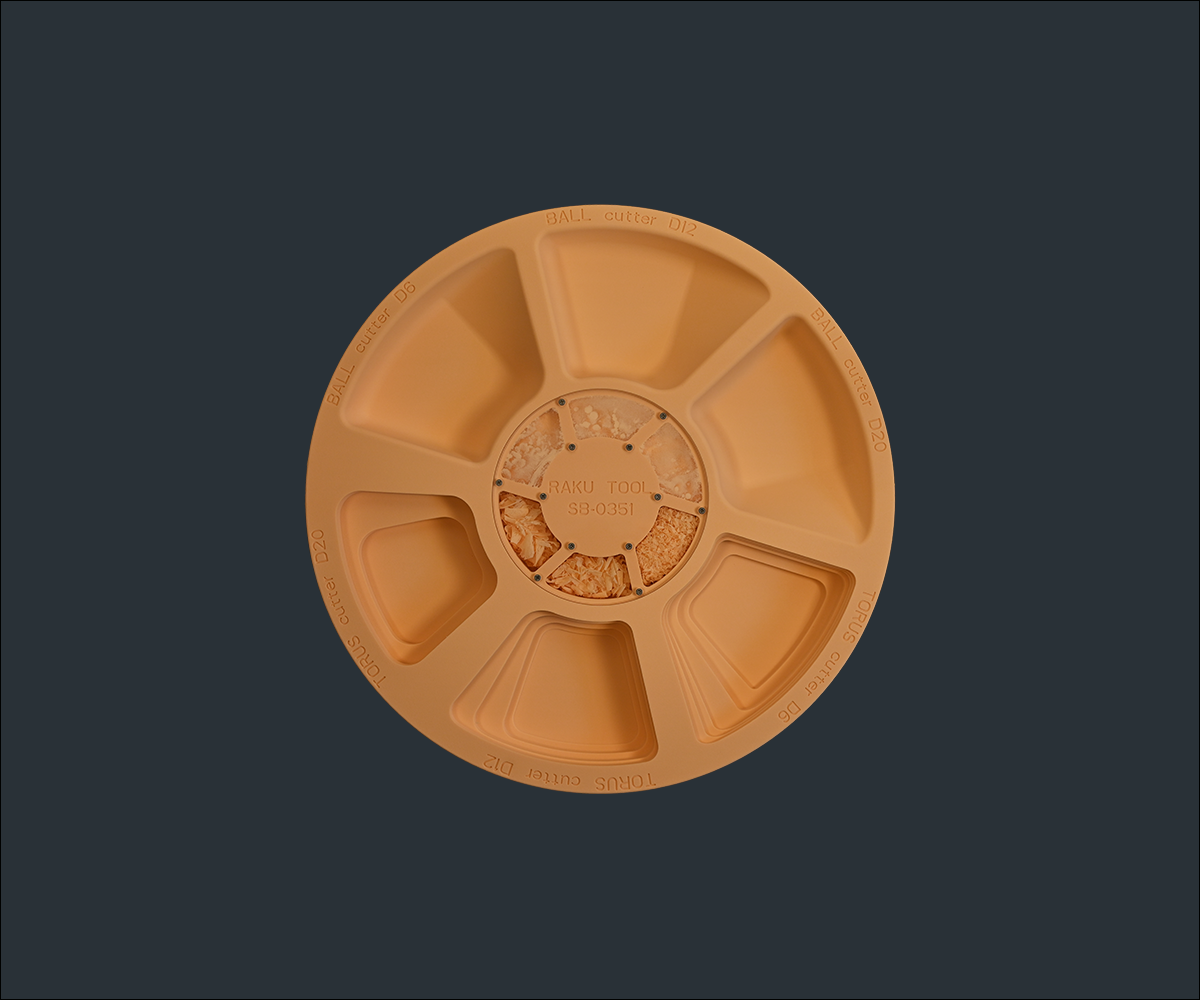

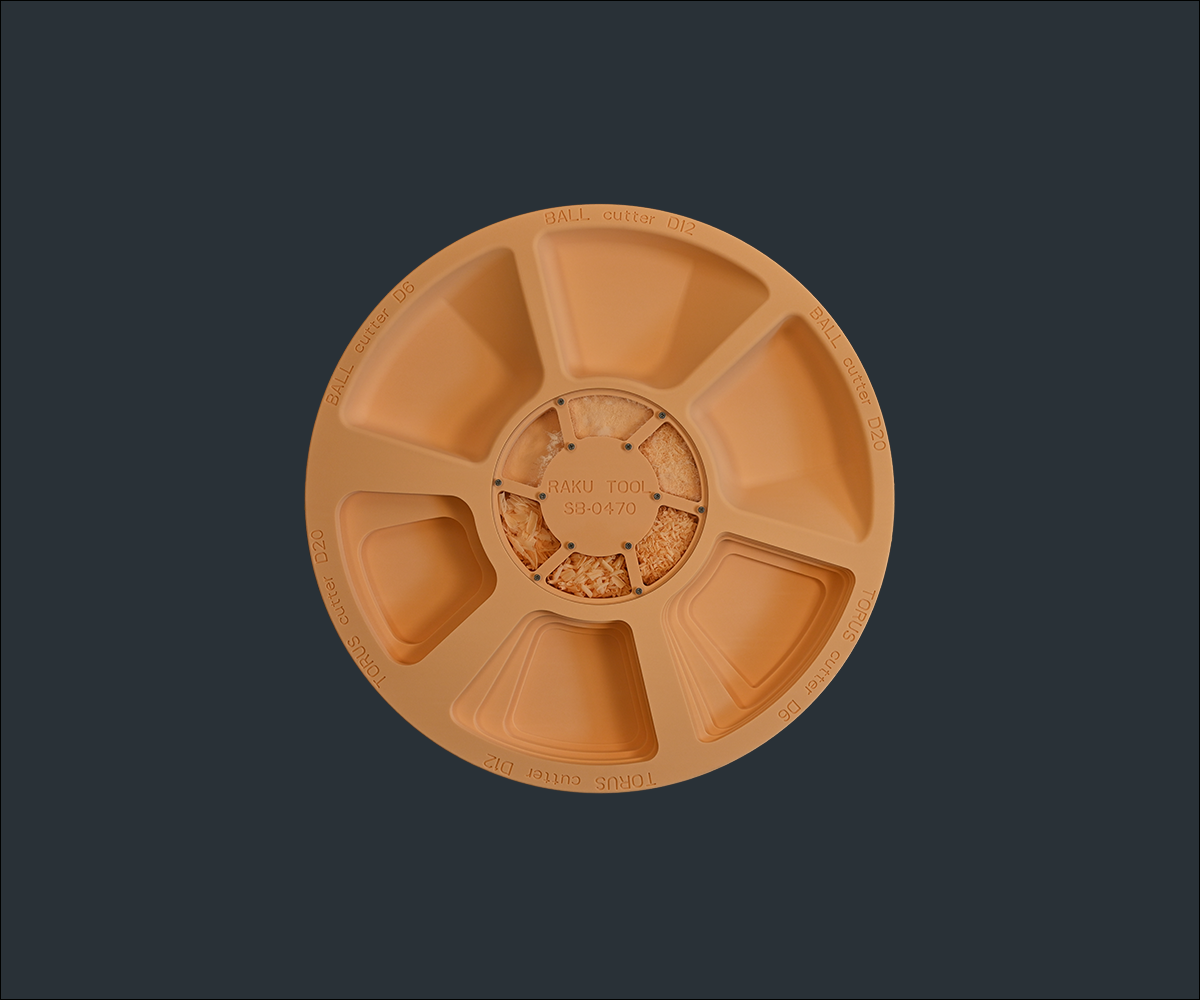

- Styling Board Materials (SB) – lightweight, precise, easy to machine: PU semi-finished products with extremely fine surface structure. Ideal for negative molds for casting, substructures for pastes, CNC test runs, design and form studies, styling, master and data control models, and negative molds. Apricot-colored versions available. Excellent manual and CNC machinability.

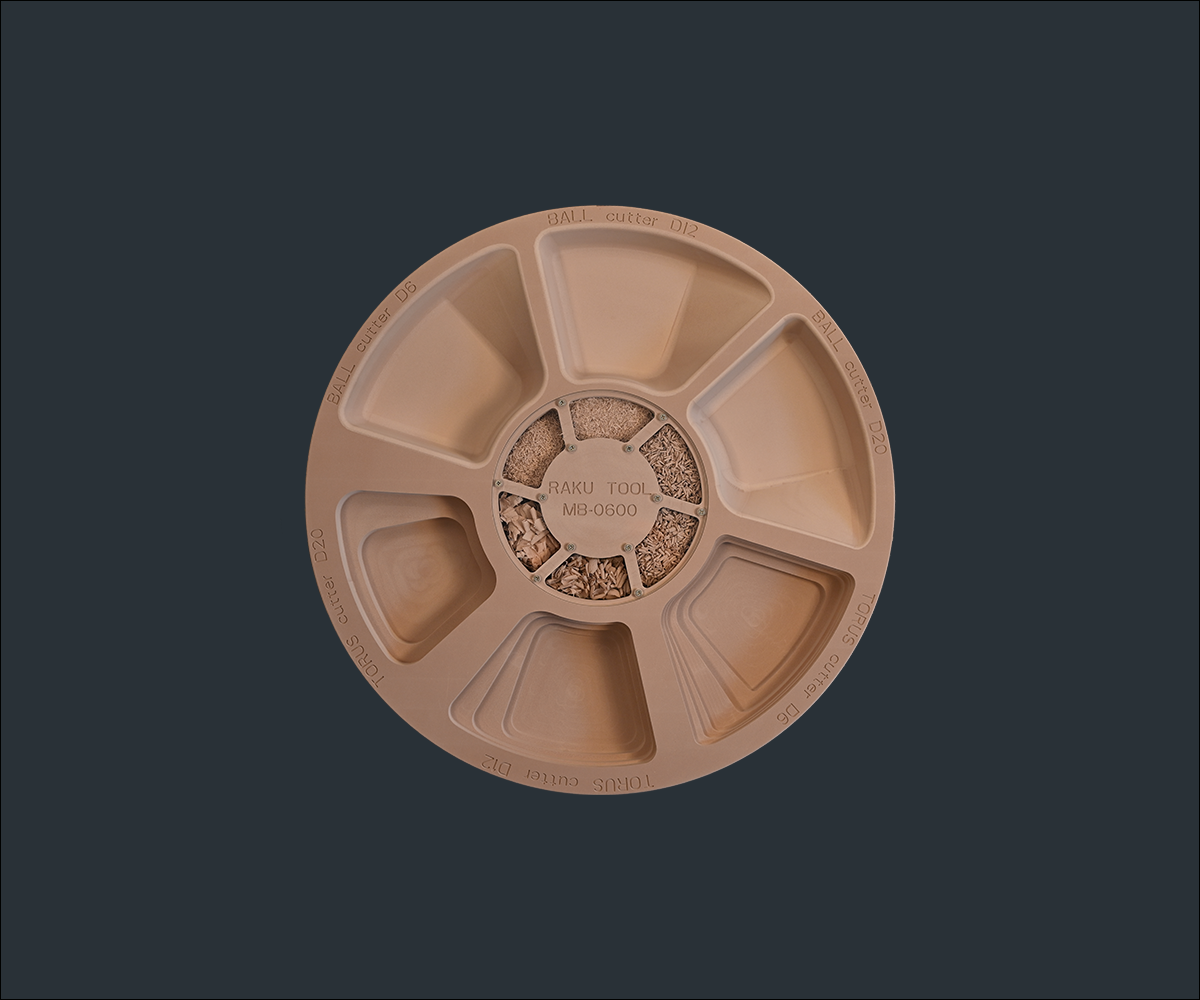

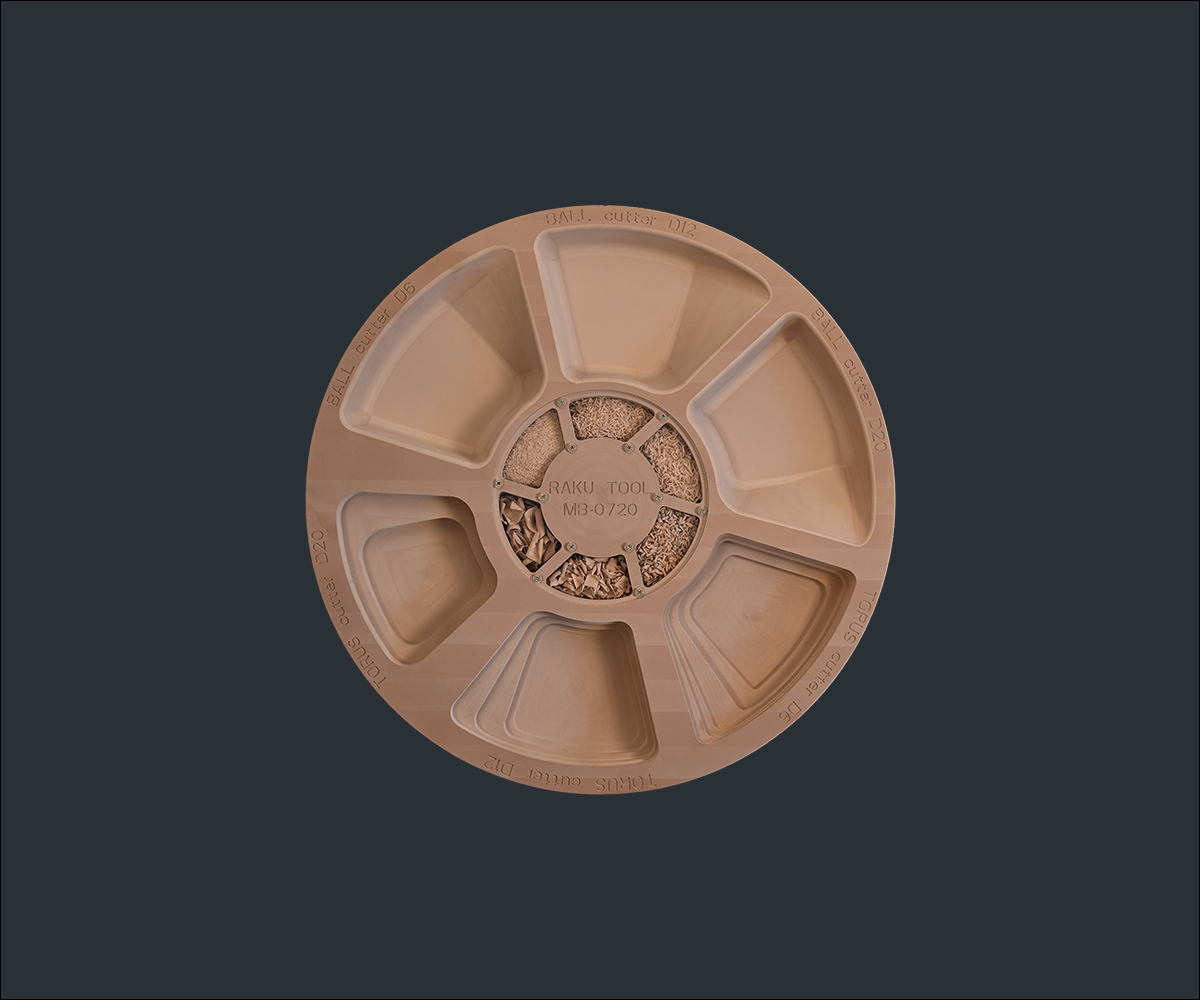

- Model Making Board Materials (MB) – dimensional stability for masters and presentation models: PU model making boards with clean chip formation, stable geometry and homogeneous surfaces. Density range 0.6–0.72 g/cm³. Perfect for master models, cubing and presentation models, design and form studies; adhesives matched in color and hardness.

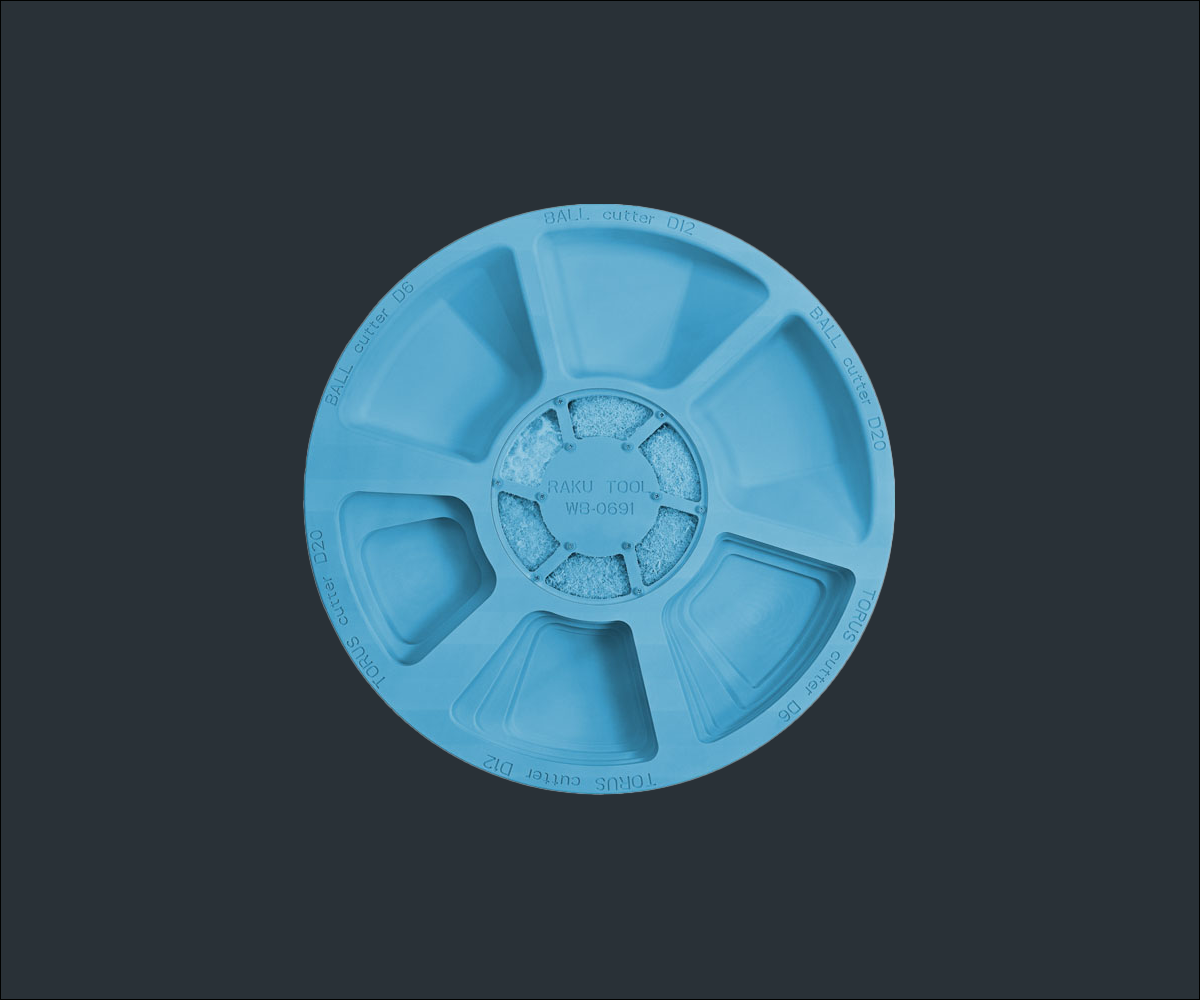

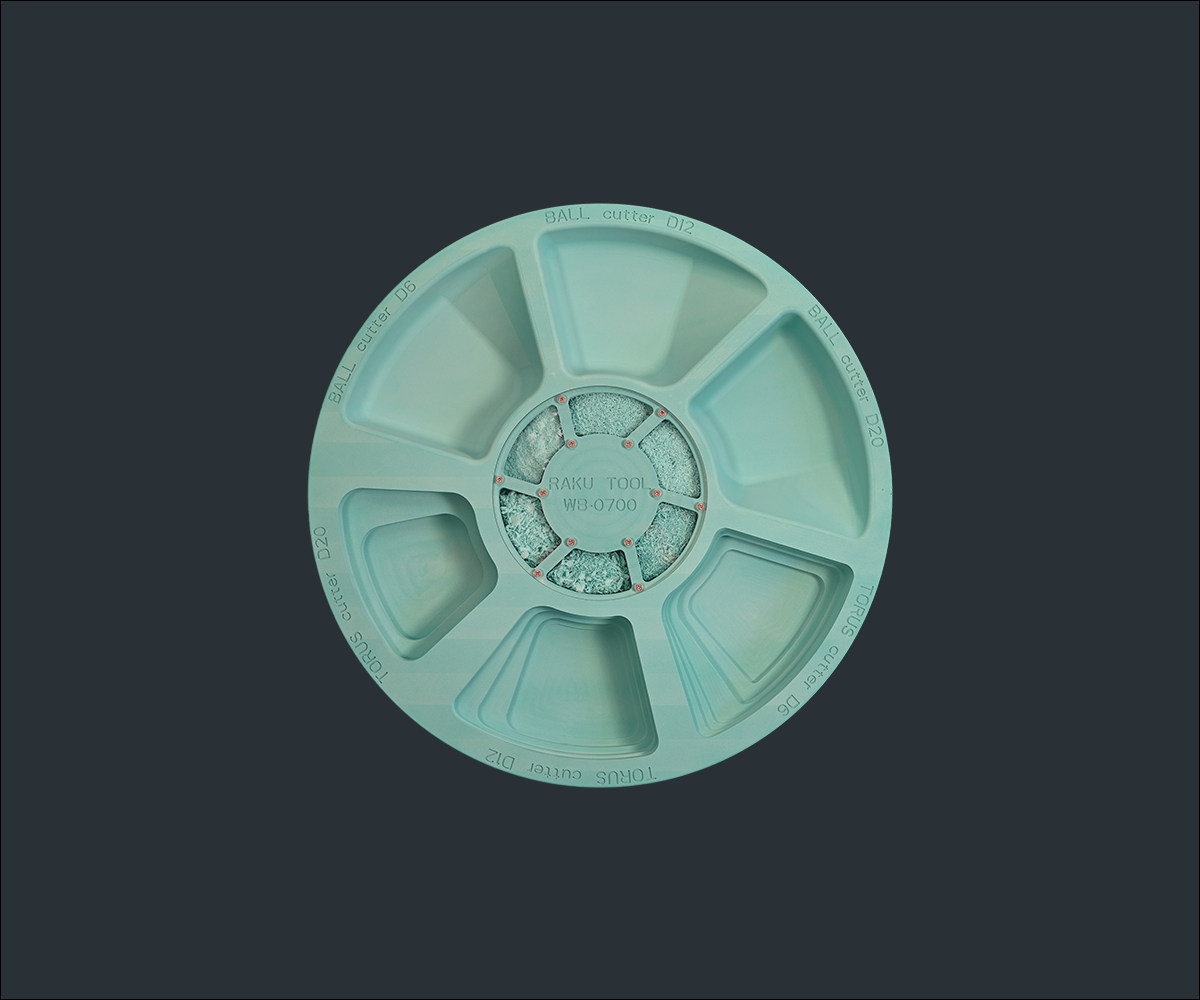

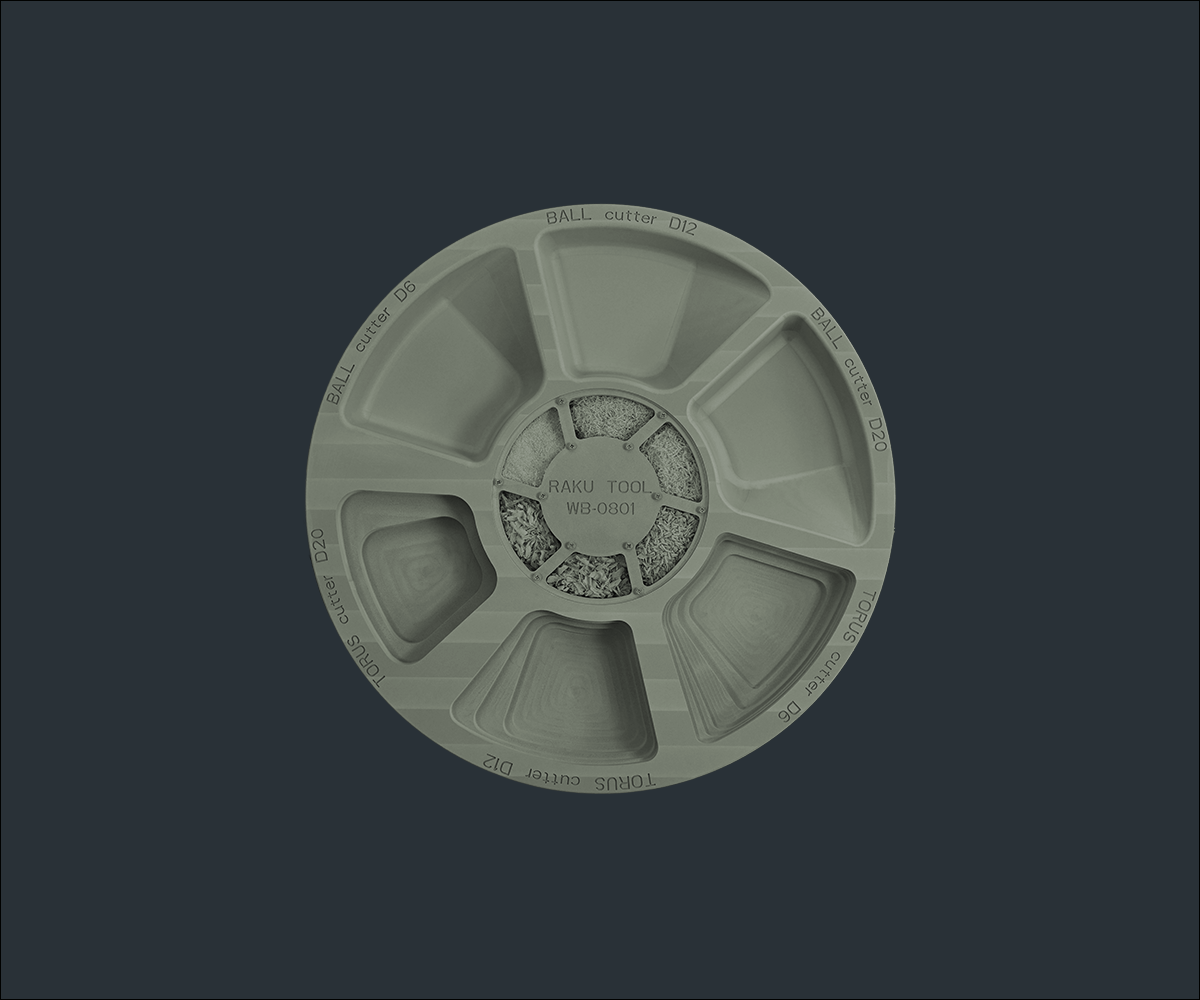

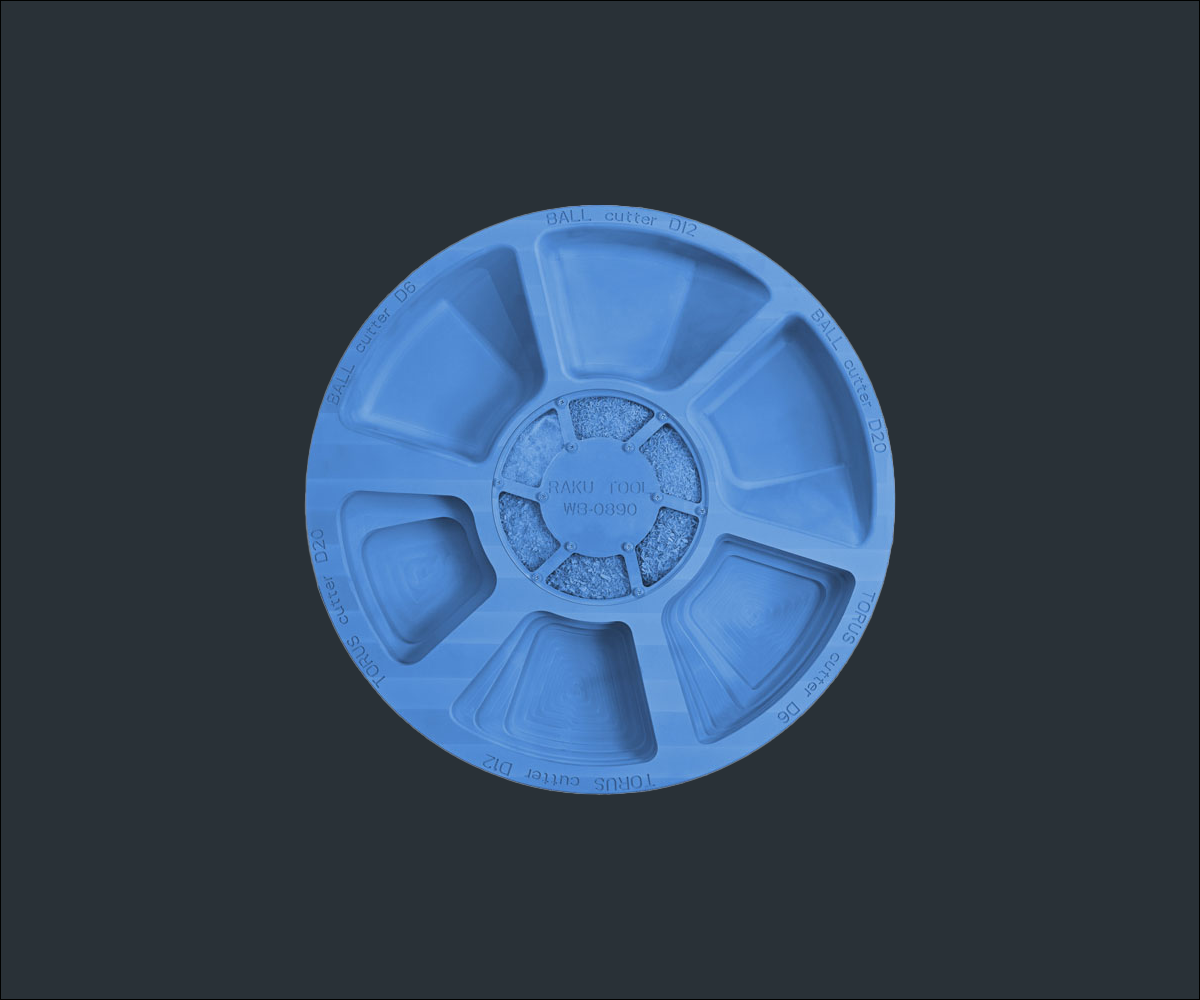

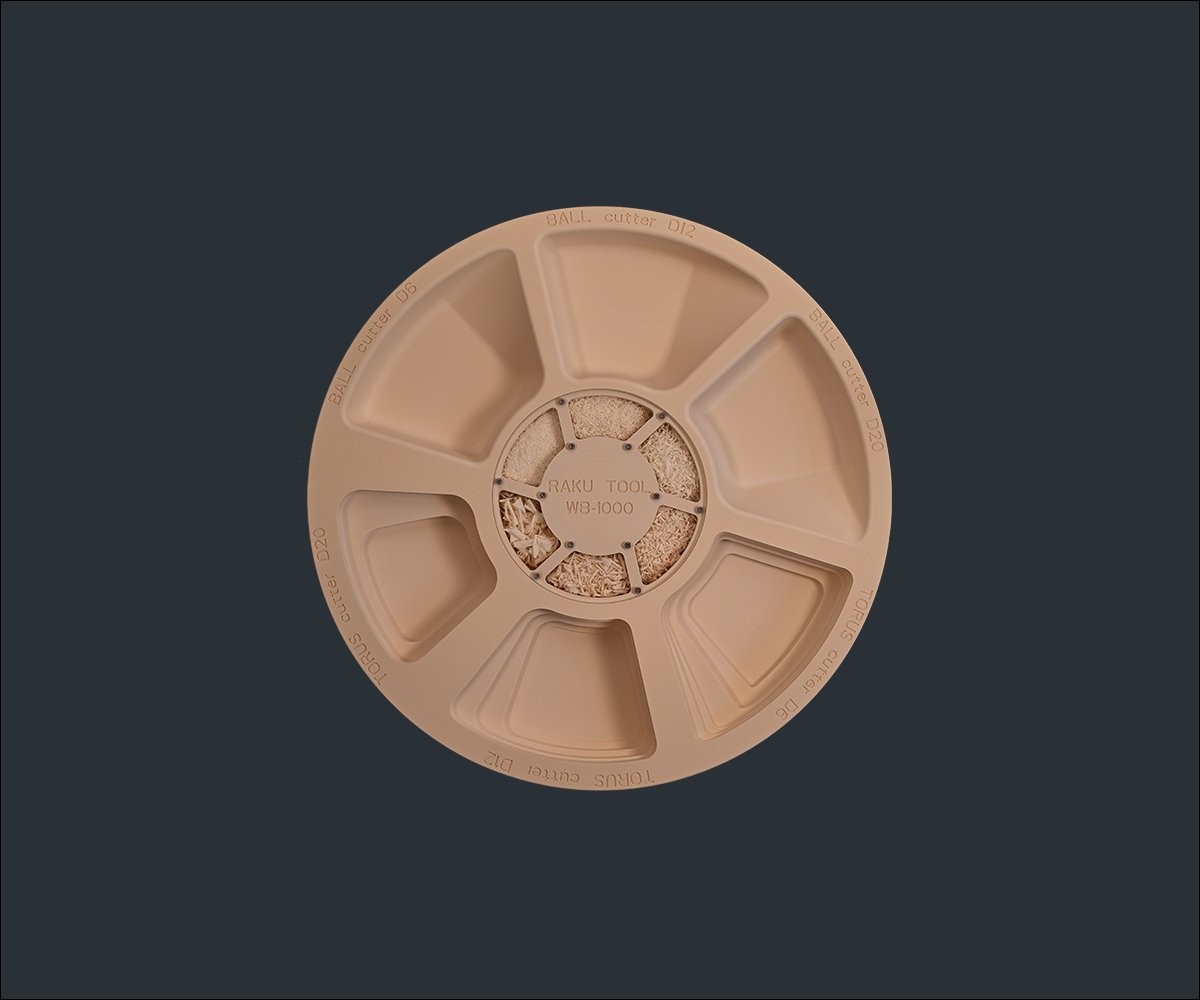

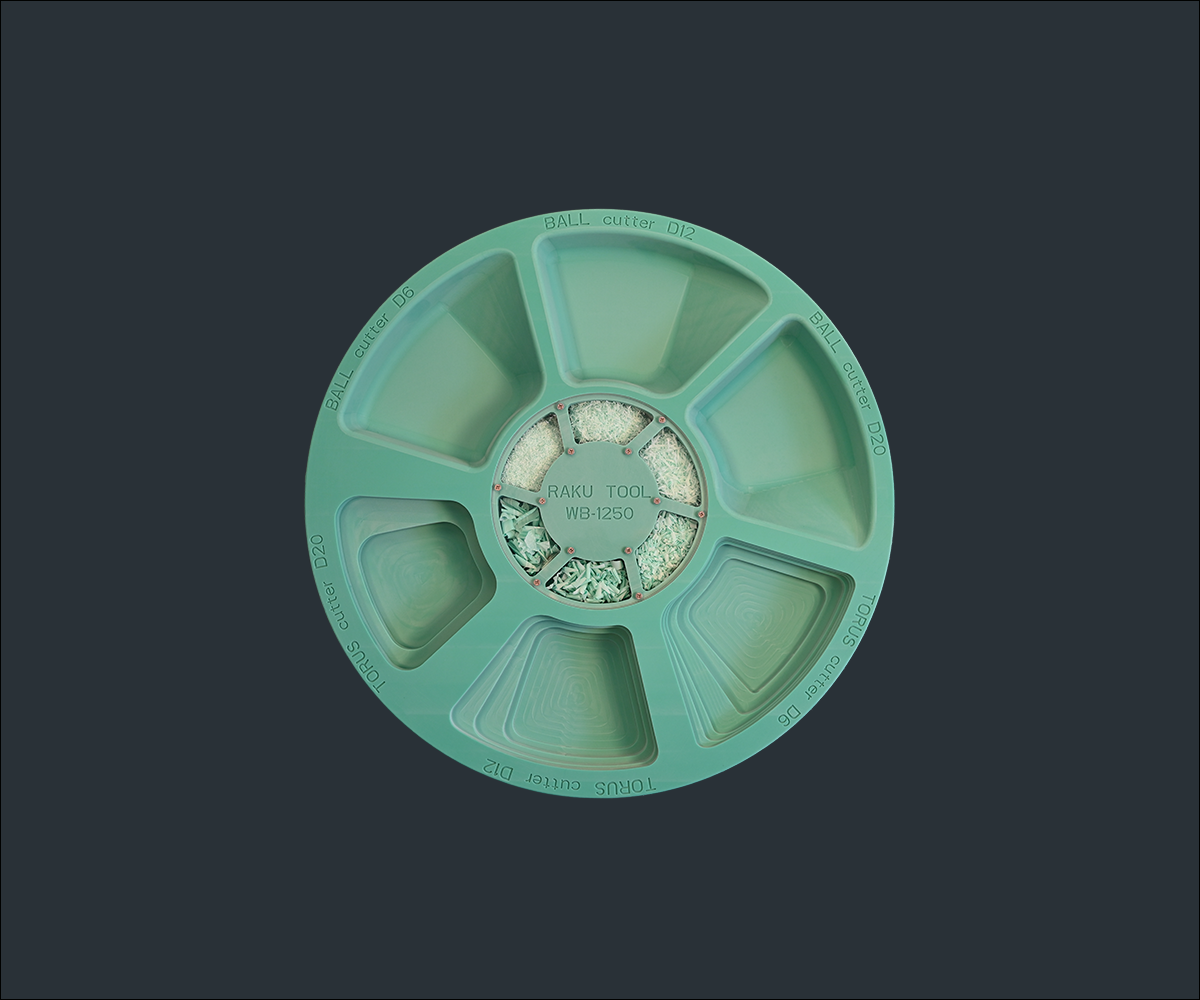

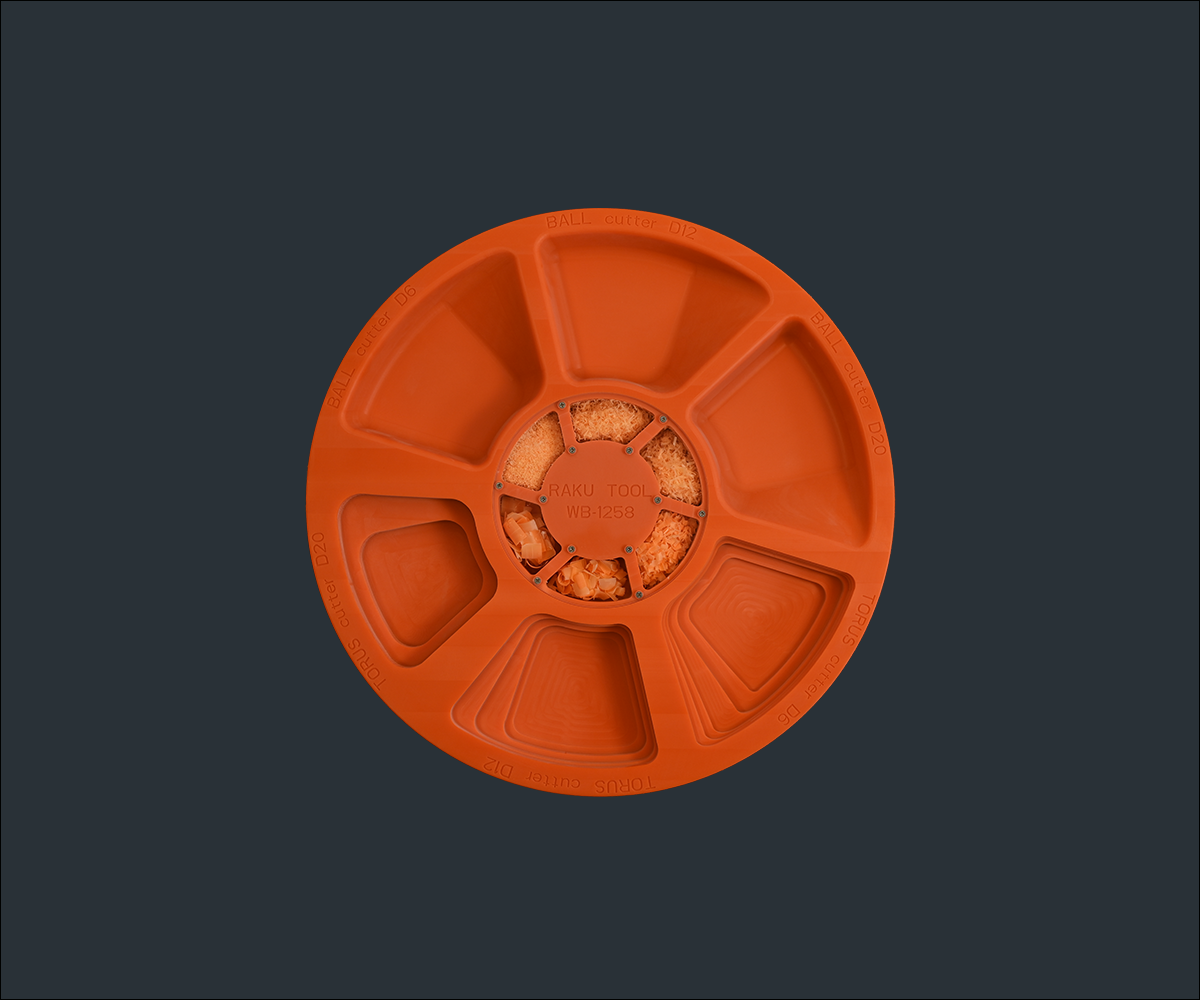

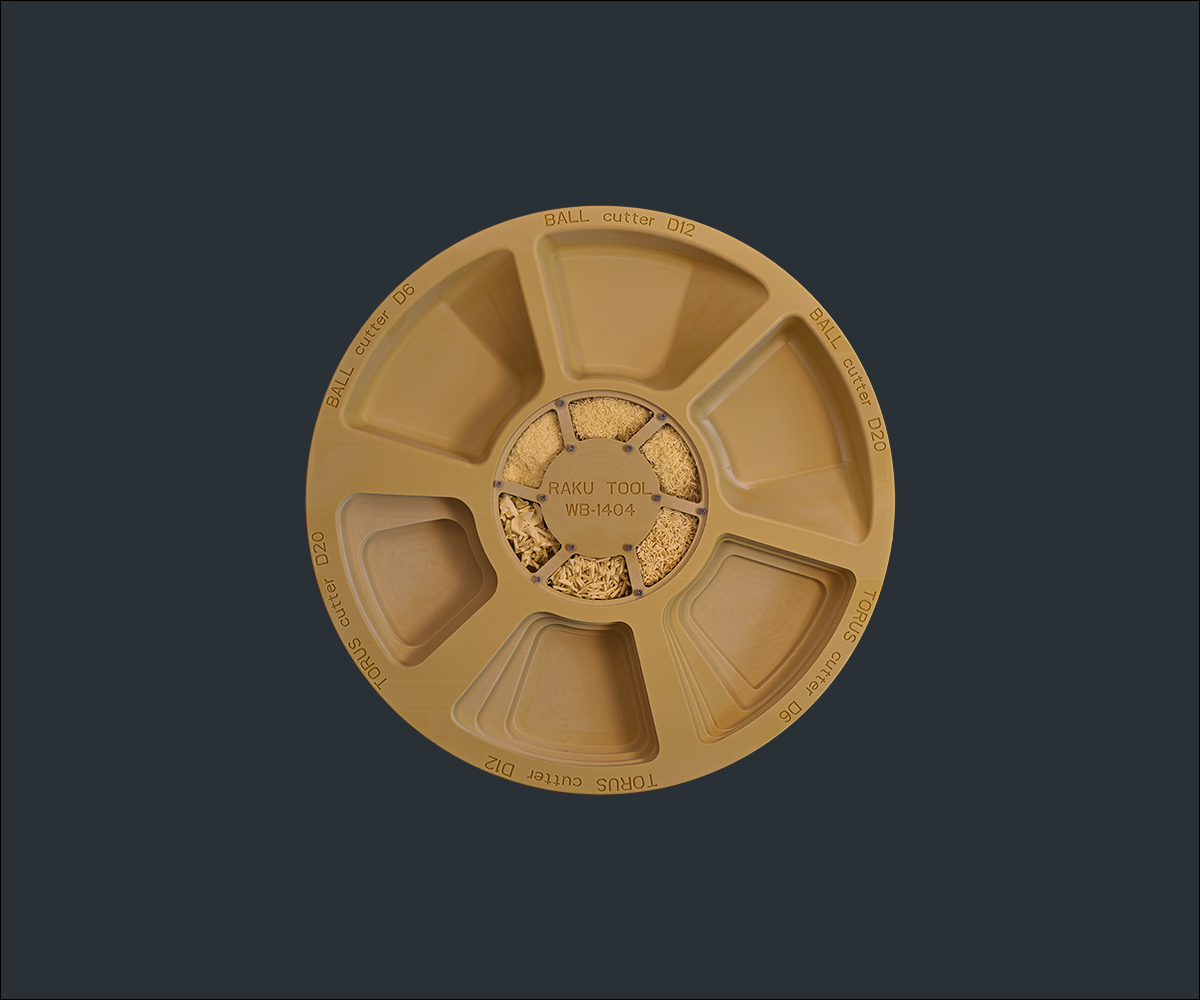

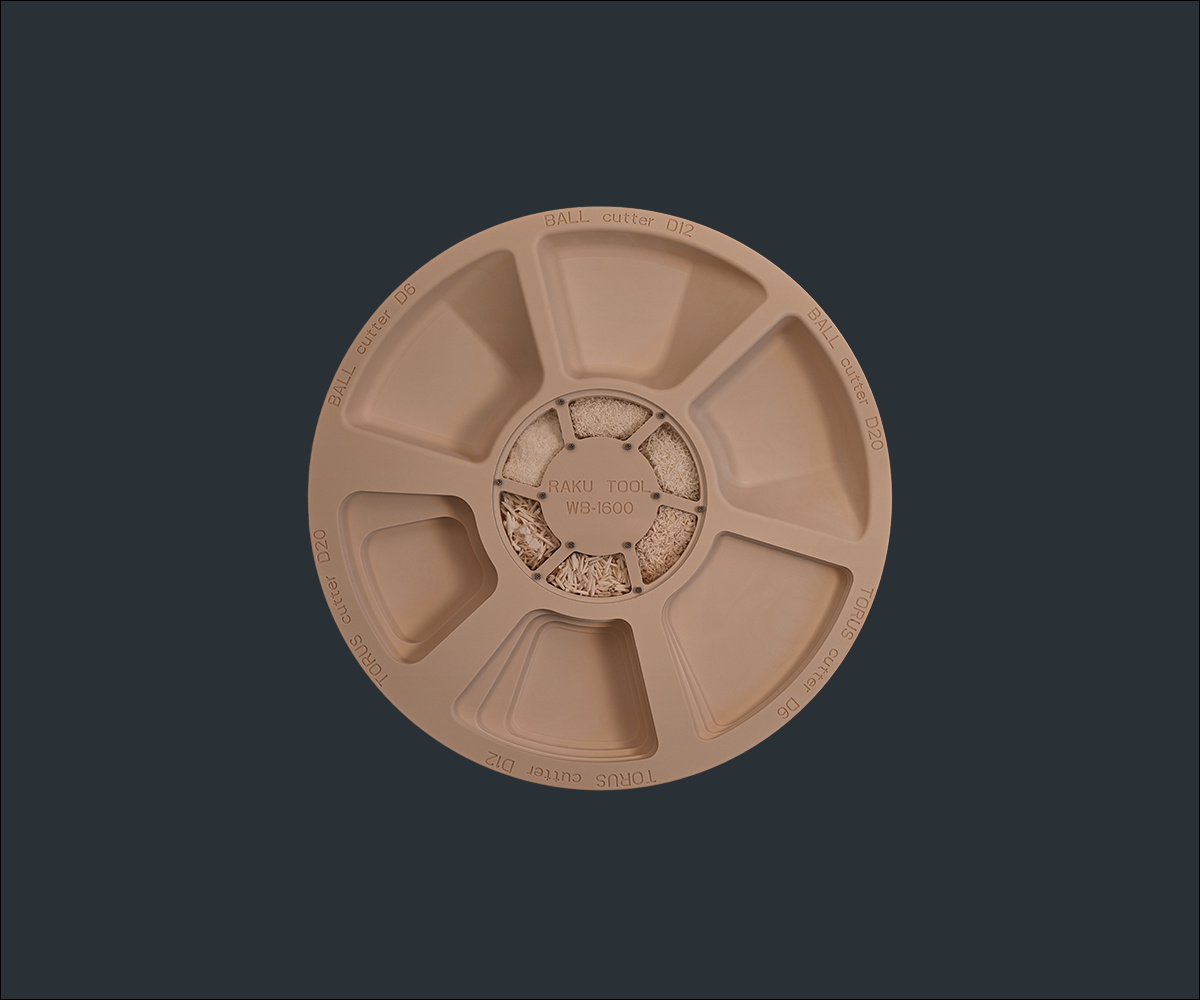

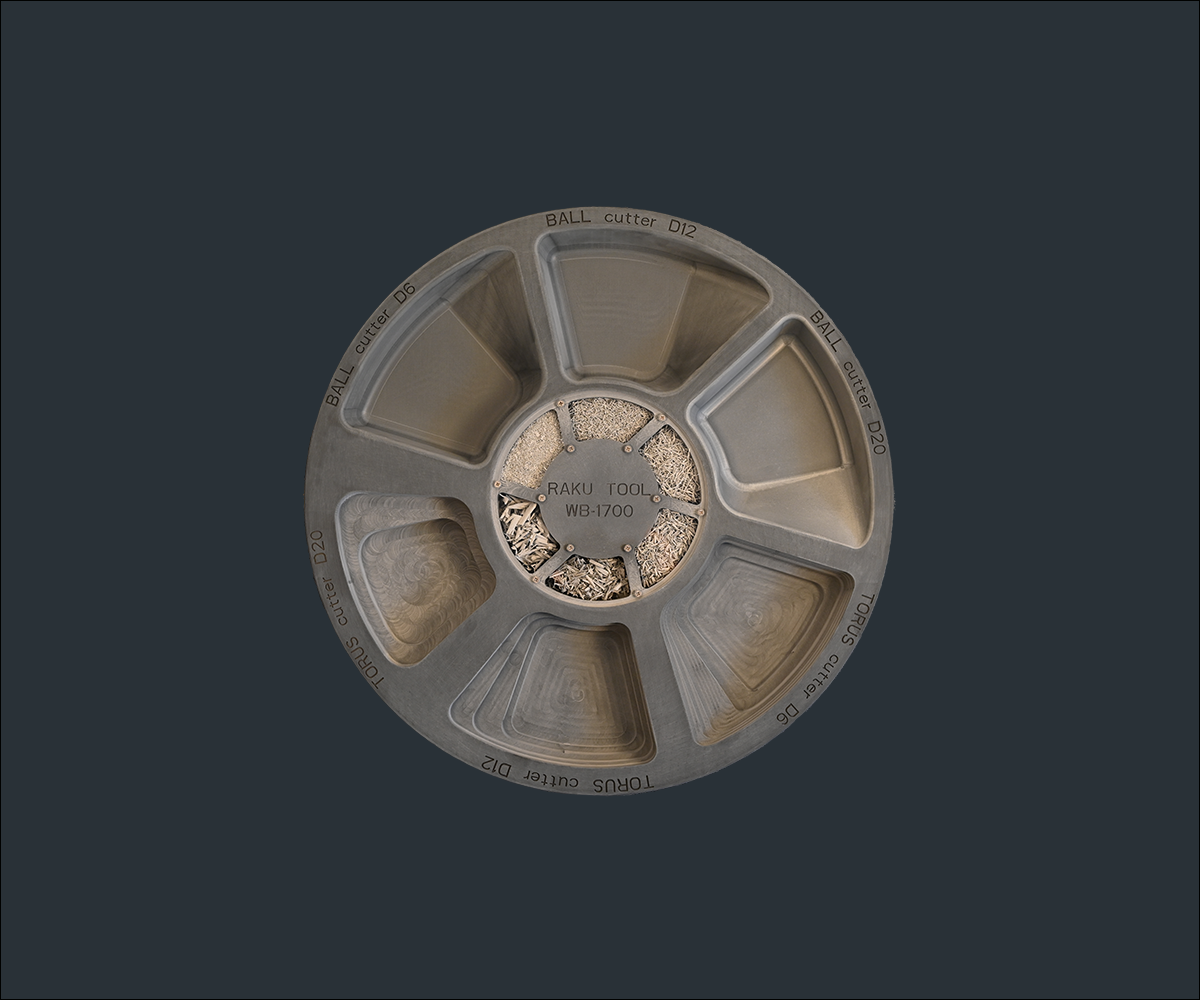

- Tooling Board Materials (WB) – epoxy and PU for demanding applications: density ranges 0.69–1.7 g/cm³, high dimensional stability, fast CNC machining. Ideal for metal forming, hammer tools, foundry tooling, molds, jigs, and layup tools. Our epoxy variants are the benchmark for layup tools in composites (prepreg), proven in automotive and aerospace.

- Adhesives – perfectly matched: 1-component and 2-component systems based on epoxy and PU. Excellent adhesion, flow behavior, easy machining, fast room-temperature cure. Precisely matched to the color and hardness of each polyurethane tooling board.

- Repair Filler – fast rebuild and repair: 2-component epoxy fillers, with properties and color perfectly aligned to the corresponding materials. Easy to machine, fast curing; hardener also available separately and compatible with standard Board Material adhesive resins.

Your Key Benefits

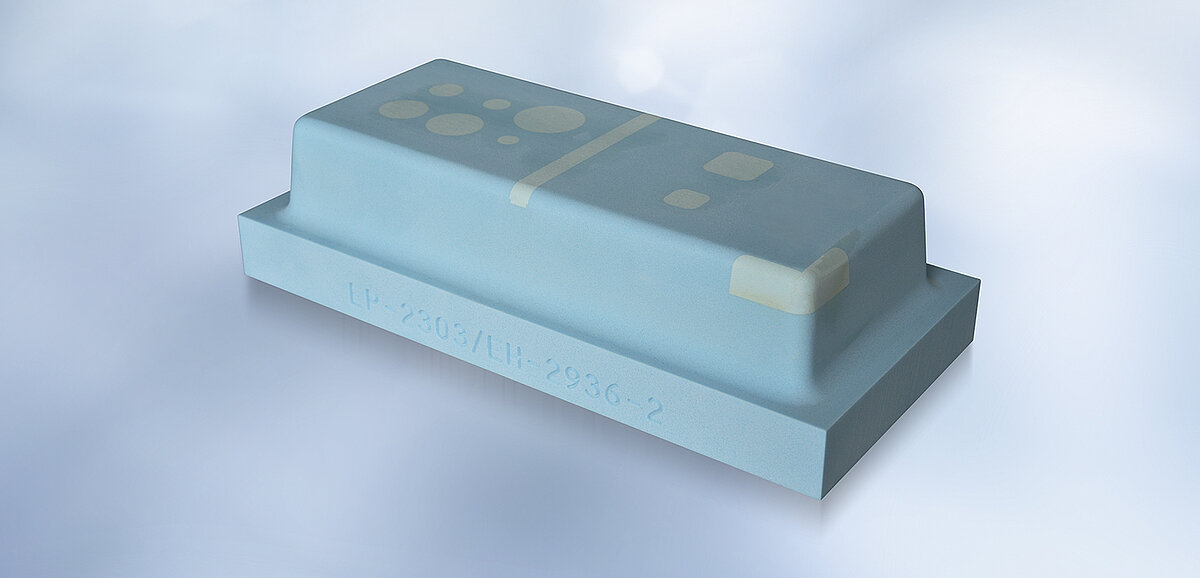

Styling Board Materials (SB) – Lightweight, Precise, Machinable

Polyurethane semi-finished products with ultra-fine surface structure – ideal for design and form studies, data control models, and negative molds. Apricot-colored versions available. Outstanding manual and CNC machinability.

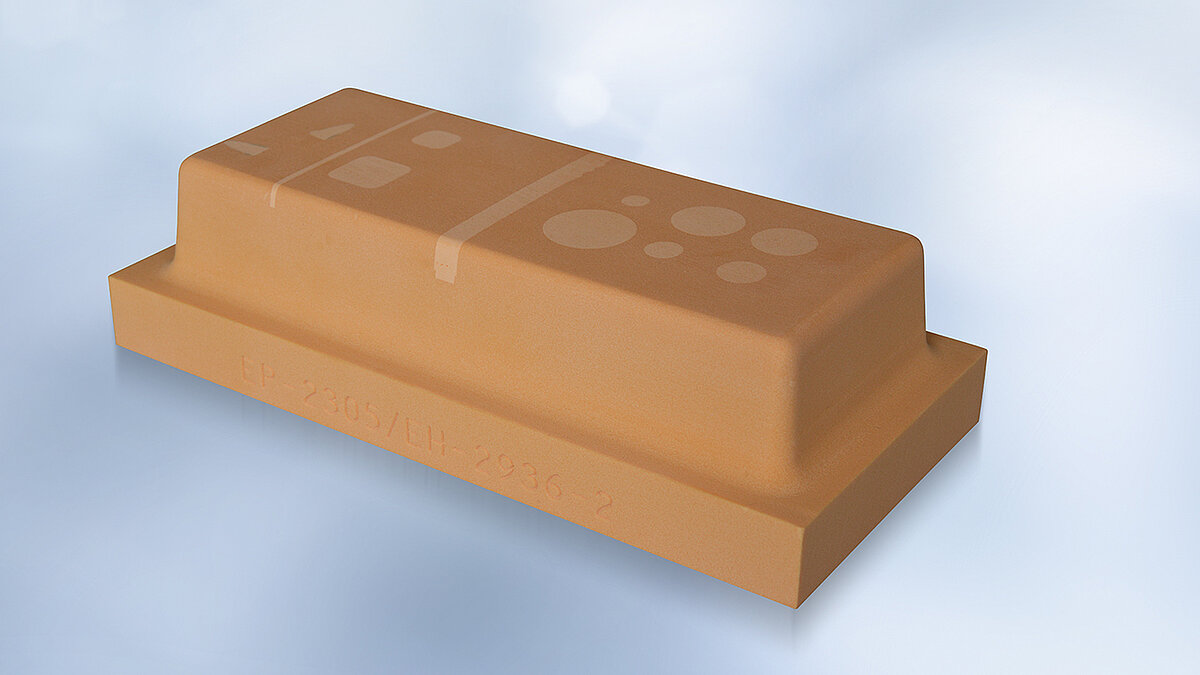

Modeling Board Materials (MB) – Dimensional Stability for Master and Presentation Models

Polyurethane model boards with clean chip formation, stable geometry, and homogeneous surfaces. Density range 0.6–0.72 g/cm³. Ideal for master models, cubing and presentation models; adhesives matched in color and hardness.

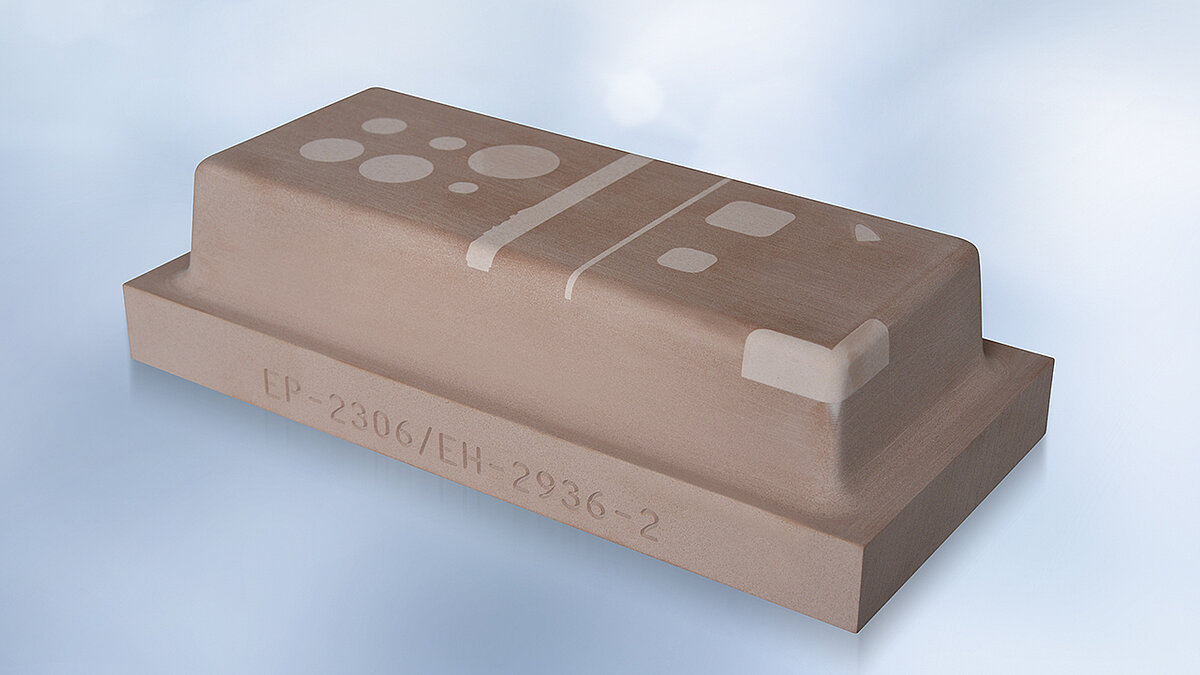

Working Board Materials (WB) – Epoxy and PU for Demanding Applications

Density ranges 0.69–1.7 g/cm³, high dimensional stability, fast CNC machining. Two epoxy variants serve as the benchmark for composite layup tools (prepreg), trusted in automotive and aerospace.

Adhesives – Precisely Matched

1-component and 2-component epoxy and polyurethane systems offering excellent adhesion, ideal flow properties, easy processing, and fast room-temperature curing. Precisely aligned with the color and hardness of each board.

Global Support. Anytime. Anywhere.