Automotive Sealing Systems:

Maximum Safety & Efficiency for Your Production

Excellent recovery capability and aging resistance ensure a long service life of the sealing foams

Applied in a groove or directly on the flat surface of the component

Compliance with the highest fire protection standards

Excellent sealing against spray water and other liquids

Reliable compensation of component tolerances while maintaining consistently high sealing quality

Outstanding adhesion properties on a wide range of materials ensures strong bonds between foam gasket and component

Your Key Benefits

For interior applications, we offer specially developed, low-emission systems that comply with VDA 270, VDA 275, and VDA 278.

Our sealing systems are approved by leading automotive manufacturers for use in both interior and exterior applications.

Sealing foams with low Shore hardness enable for very low installation forces.

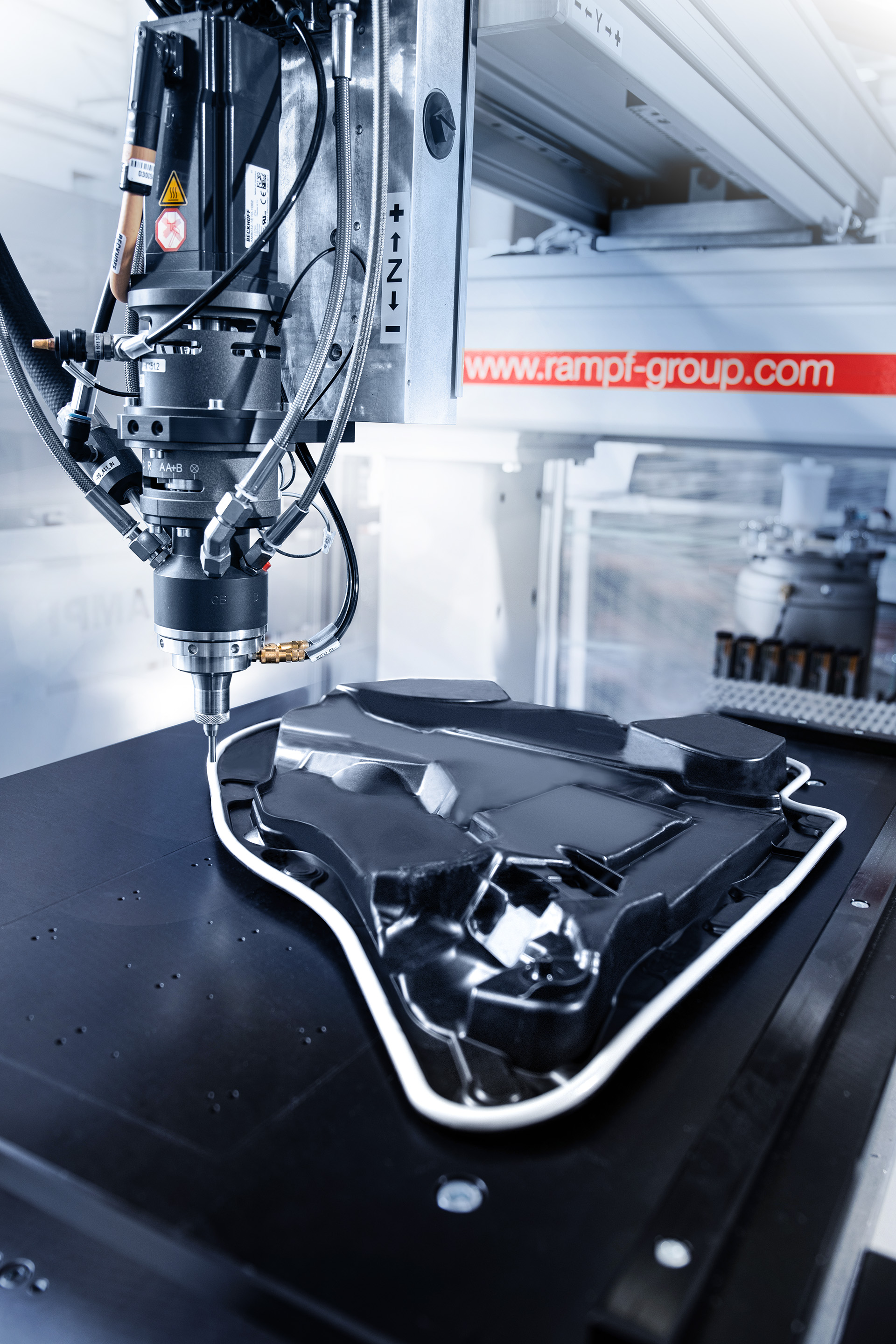

The polyurethane sealing foams are applied directly to the door module in a fully automated process, ensuring consistently high quality.

The fast-curing foam gaskets based on Speed Technology enable further handling of the components after only a very short time.

Two‑component PU foam gaskets provide reliable sealing for automotive headlights and brake lights by delivering long‑lasting protection against moisture, dust, and chemicals.

With their excellent resilience and superior ageing resistance, our polyurethane‑ and silicone‑based sealing systems are trusted across a broad spectrum of automotive applications.

Global Support. Anytime. Anywhere.