Advanced Composite Engineering Solutions

Engineering Excellence, Optimized for Performance

Engineering Innovation at Every Level

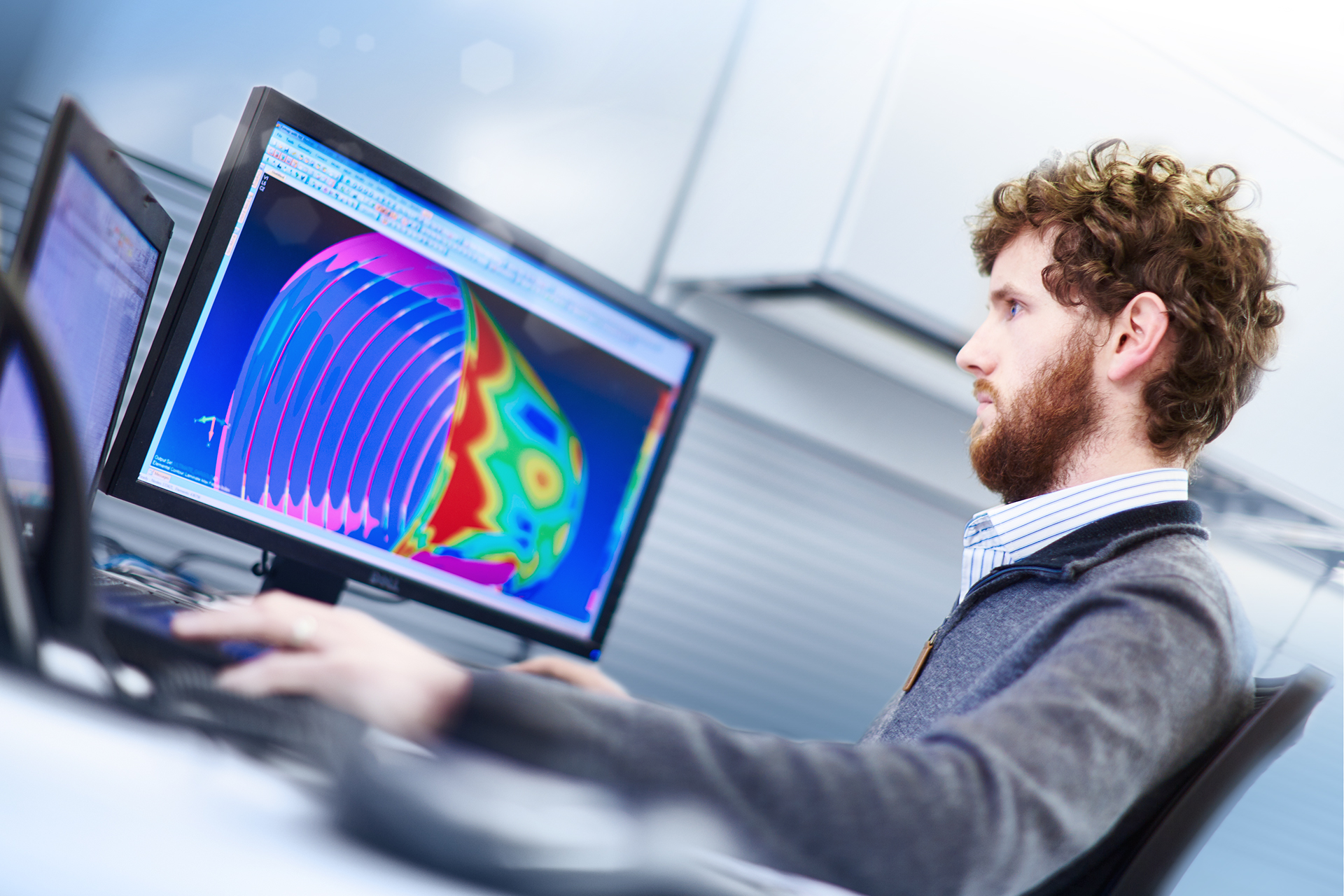

RAMPF delivers composite engineering services that enable high-performance structures across aerospace, defense, and industrial applications. Designed for maximum strength-to-weight efficiency, advanced durability, and design precision, these solutions are trusted by industry leaders requiring mission-critical performance.

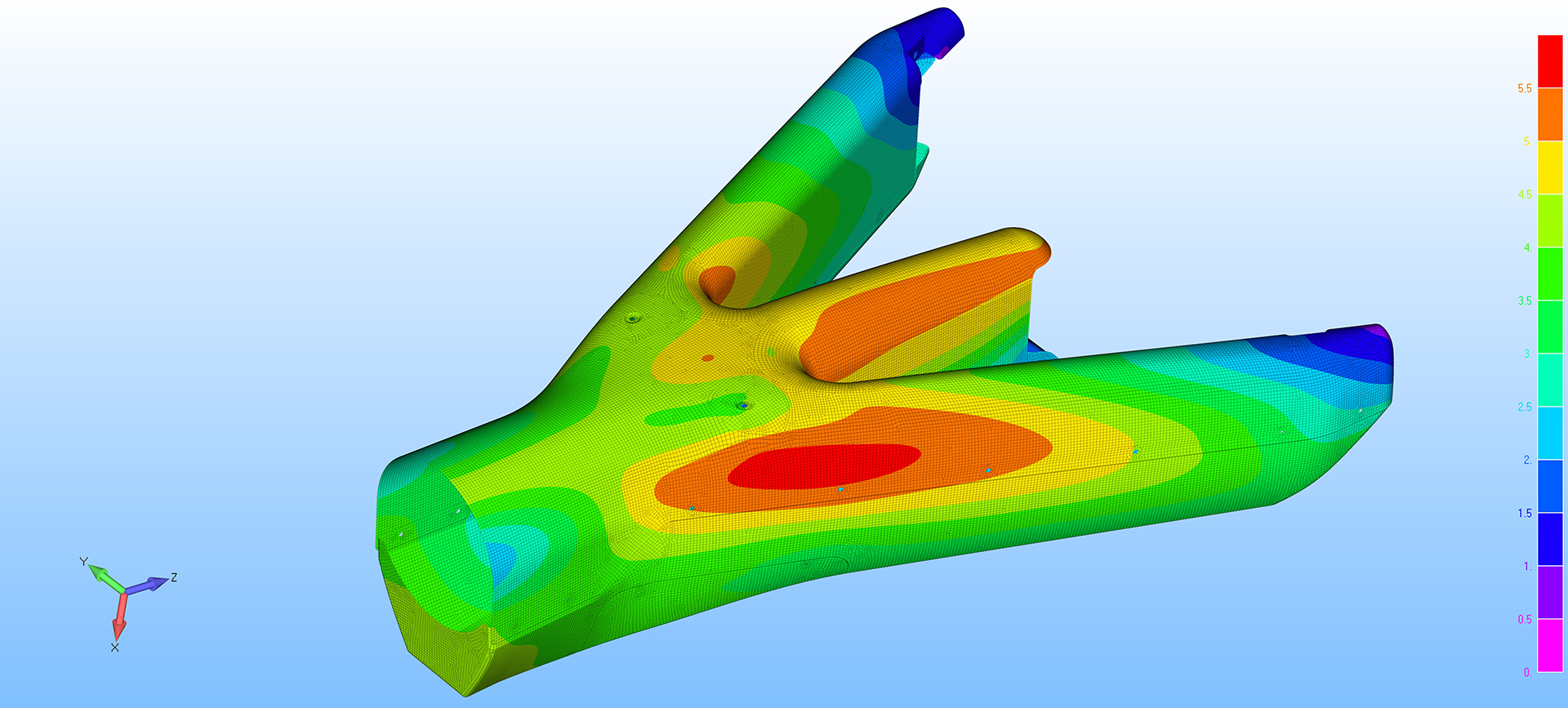

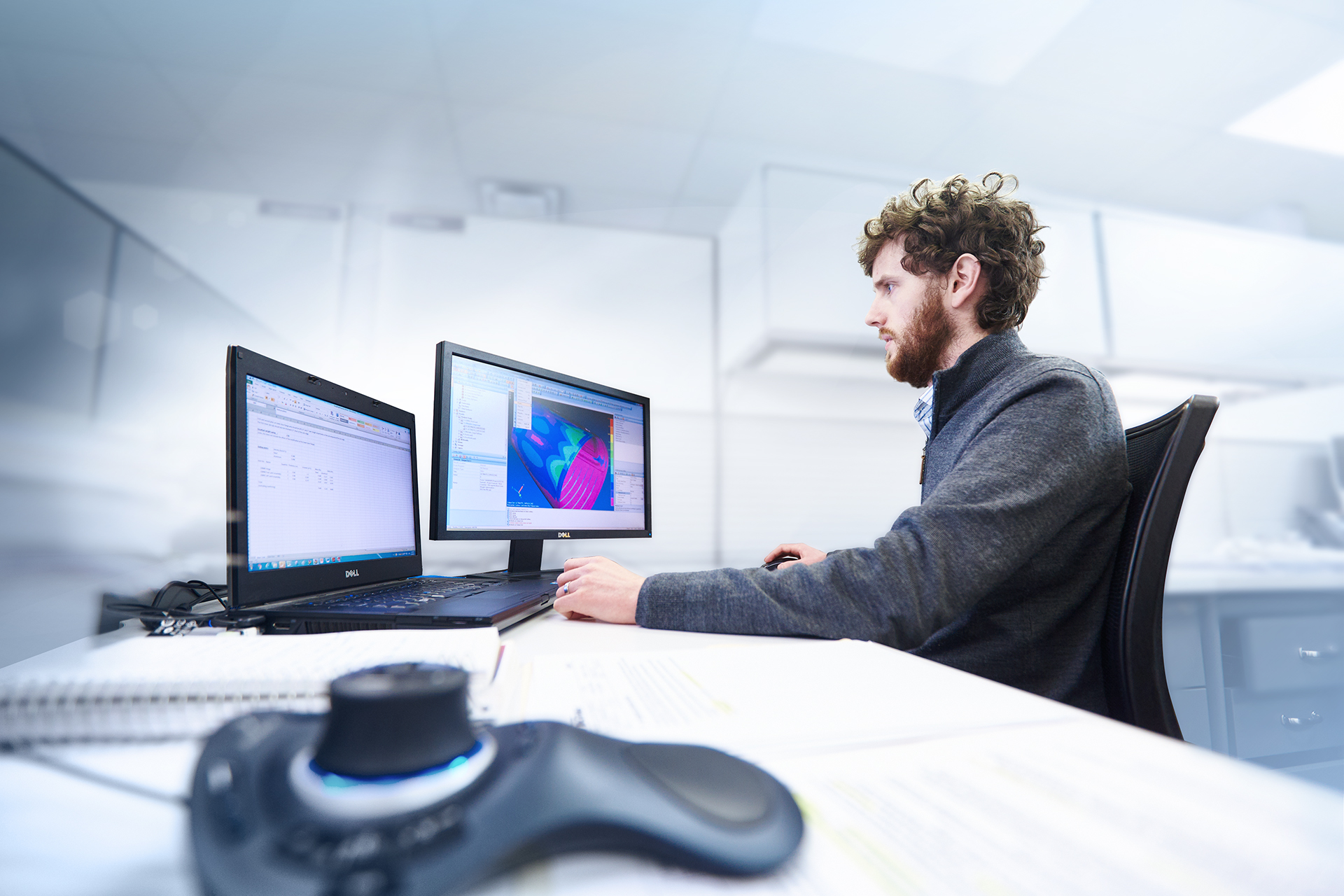

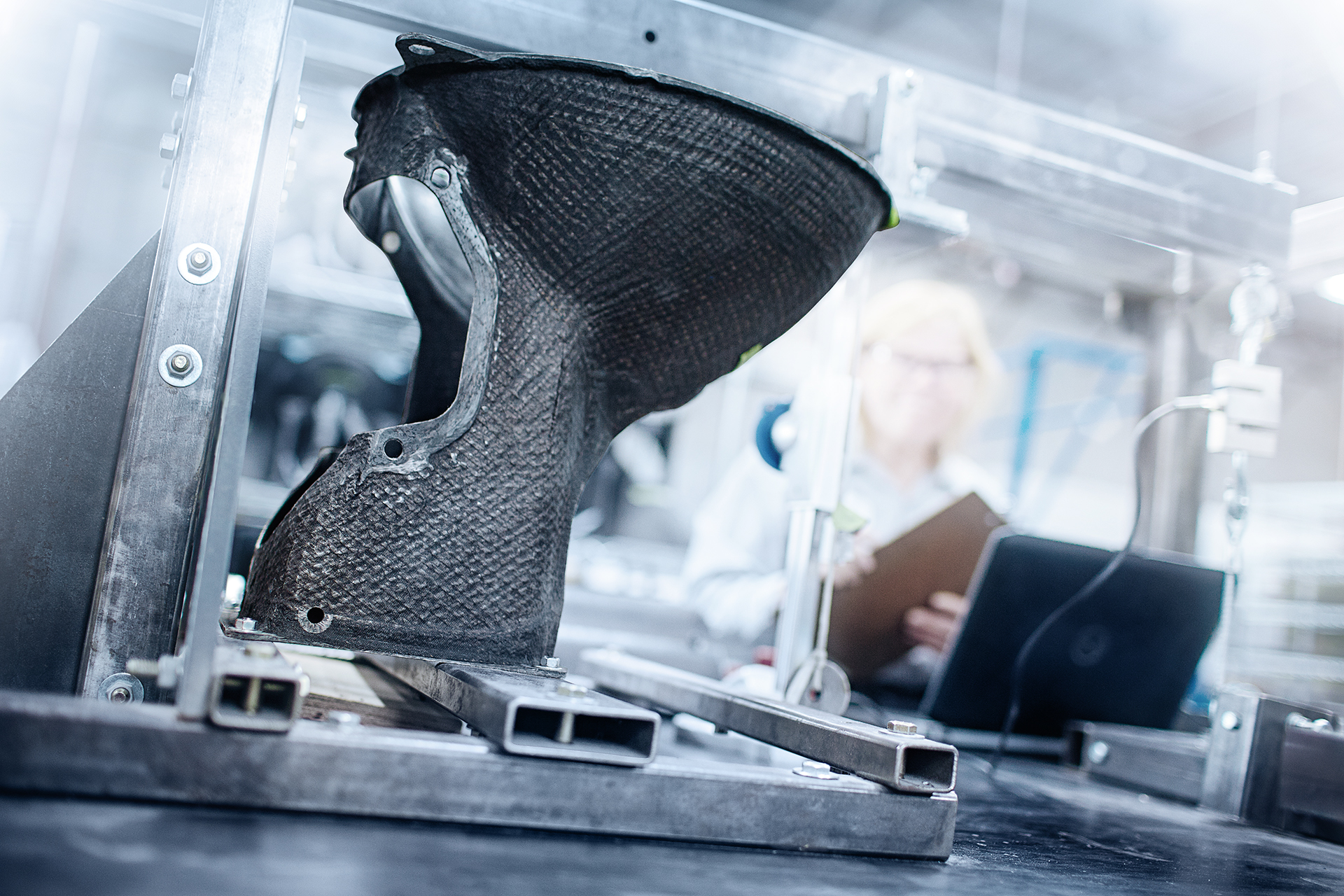

Services span the full engineering lifecycle—from Finite Element Analysis (FEA) and 3D modeling to tooling development and process optimization—all executed with advanced software, vertically integrated systems, and a commitment to production-readiness.

Your Key Benefits

Partnering for Smarter Composite Engineering

RAMPF drives innovation in composite engineering through expertise, precision, and a fully integrated development process. Whether the challenge involves structural analysis, tailored fiber placement, or efficient part manufacturing, solutions are tailored for performance, speed, and scalability.

Enabling the next generation of lighter, stronger, and smarter composites—built for real-world performance.

Global Support. Anytime. Anywhere.