Model and Mold Making

for Maximum Efficiency and Quality

For more than 40 years, RAMPF has stood for innovative solutions in tooling and mold making. Our materials and systems combine efficiency, precision, and sustainability. With Close Contour products, customized blocks, and pastes, we enable highly efficient manufacturing of models and molds—seamless, dimensionally stable, and resource‑saving. Rely on our expertise for top-tier quality and maximum flexibility.

Your Key Benefits

Close Contour Pastes (CP)

Seamless precision for large-scale models

RAKU® TOOL Close Contour Pastes are two-component epoxy systems for close contour mold making and model production. Applied directly onto the substructure, they cure quickly and can be milled precisely according to your CAD data. The result: homogeneous surfaces, minimal reworking, and maximum efficiency. Ideal for design, styling, and master models, as well as rotor blade and boat models.

Repair Systems for Close Contour Pastes

Precise repairs without compromise: RAKU® TOOL repair systems are perfectly matched to our Close Contour pastes and ensure seamless processing. The easy‑to‑mix, two-component epoxy systems can be applied with a spatula and adhere even at 20 mm layer thickness on vertical surfaces without sagging. With mechanical properties that match the cured pastes, fast curing, and optimal processing at 20–25 °C, you achieve reliable results at every step.

Epoxy Pastes (hand-applied) (EP)

Maximum freedom in manual modeling: RAKU® TOOL epoxy hand pastes are easy to apply, shape, and finish manually. Whether apricot-colored styling paste or brown model-making paste—both offer low density, excellent adhesion, and can be shaped perfectly with woodworking tools. Ideal for design models, styling projects, master models, and molds requiring fast processing and high detail accuracy.

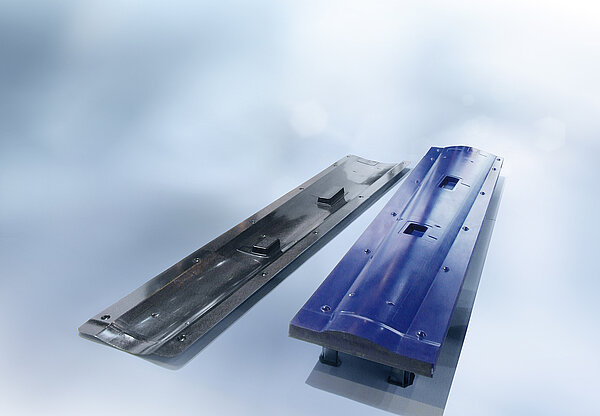

Close Contour Casting (CC)

Precision preforms for maximum efficiency: RAKU® TOOL Close Contour Castings are close contour polyurethane castings produced near net shape. Based on your CAD data, a three-dimensional casting with a fine, seamless surface is created using the specialized casting process at RAMPF Advanced Polymers. With reduced material removal, less finishing work, and fast machinability, you save time, cost, and production waste.

Close Contour Blocks (CB)

Custom block materials for highest precision: RAKU® TOOL Close Contour Blocks are polyurethane or epoxy blocks individually manufactured to customer specifications and delivered as rectangular, unmachined specialty blocks. Their close contour geometry significantly reduces material use and machining effort—ensuring efficient processes, seamless surfaces, and precise results in styling, master, and data control models, tools, fixtures, and thermoforming molds.

Global Support. Anytime. Anywhere.