Epoxy Casting Resin for Tooling and Model Making

High Strength, Fast Curing

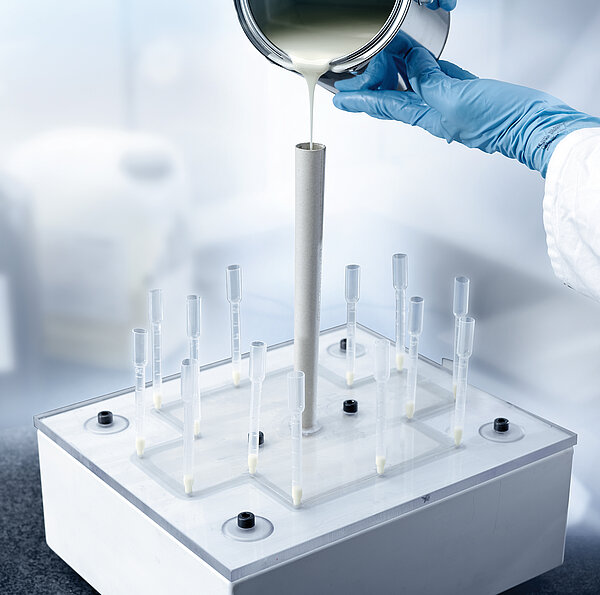

RAKU® TOOL liquid systems deliver high-performance, high‑quality, and consistently reproducible results for tooling, mold making, model construction, and composites. Our epoxy casting resin systems, polyurethane systems, and polyurea systems support solid and face casting, laminating, resin infusion, and rapid prototyping. Adjustable pot lives, reliable room‑temperature or post-curing, and easy customization with coloring pastes and fillers ensure dimensionally stable molds, tools, and parts with exceptional surface quality.

Liquid Materials for state-of-the-art modeling

RAKU® liquid epoxy & polyurethane systems encompass a large selection of innovative and efficient products for various manufacturing techniques, build-up methods, and applications. Our chemists also develop customized systems quickly and economically. Dedicated and prompt technical support is provided by our team of experts.

Find out more about our liquid materials for state-of-the-art modeling

Properties and Functions

- Versatile systems: Epoxy solutions, polyurethane solutions, and polyurea solutions for a wide range of applications.

- Optimized curing: Adjustable pot lives and temperature resistance for maximum process flexibility.

- Excellent surface quality: From rigid to flexible, abrasion-resistant to polishable.

- High chemical and abrasion resistance: For durable, high-performance components.

- Easy processing: Excellent degassing behavior and fast demolding.

Your Key Benefits

- Epoxy casting resin, polyurethane casting resin, and polyurea casting resin

Solid and face casting, flexible pot lives, high temperature resistance; excellent workability. - Fast Cast systems

Short curing cycles, rapid demolding, high strength; ideal for models, core boxes, and pattern plates. - Rapid Prototyping

2‑component PU systems for functional prototypes and small series, easy and quick imitation of thermoplastics like PE, PP und ABS. - Laminating resins (Epoxy)

Excellent wetting properties for complete fiber impregnation, stiff to ultra-strong laminates for automotive, aerospace, and marine applications.

- Gelcoats and coupling layers

Premium surfaces, excellent layer adhesion to backing, polishable, and highly durable. - Resin infusion

Long pot life, high temperature resistance, efficient fiber impregnation under pressure and vacuum – ideal for high‑performance composites using infusion resin. - Additives: Color pastes and fillers

Tailored color, weight, flow behavior, and mechanical properties.

Gelcoats

Perfect surfaces for the highest demands. RAKU® TOOL gelcoats deliver excellent mechanical and chemical performance for molds and components. A thin application creates surfaces ranging from rigid to flexible, abrasion-resistant to polishable – easy to apply and highly precise. Ideal for model making, tooling, and demanding industrial applications.

Epoxy Systems

Coupling Coat

A strong bond for perfect results. The RAKU® TOOL coupling layer ensures optimal adhesion between surface resin and backing structure. Easy application, uniform thickness, and outstanding heat resistance – ideal for molds, tools, and durable parts.

Epoxy Systems

Laminating Resins

Lightweight, stable, and versatile. RAKU® TOOL laminating resins produce high-strength molds and components across industries like aerospace, automotive, and model making. Solvent-free, easy to process, and with excellent wetting properties for maximum strength and precision.

Epoxy Systems

Laminating Pastes

Maximum stability in a single step. RAKU® TOOL laminating pastes enable fast, efficient production of molds, jigs, and fixtures. Easy to mix, simple to apply, and capable of high layer thickness in one pass – robust and precise at room temperature.

Epoxy Systems

Infusion Systems

Engineered for high‑strength, lightweight structures. RAKU® TOOL infusion systems offer excellent wettting properties, flowability, and temperature resistance. Perfect for composite manufacturing under pressure and vacuum, delivering top-quality fiber-reinforced parts with infusion resin.

Epoxy Systems

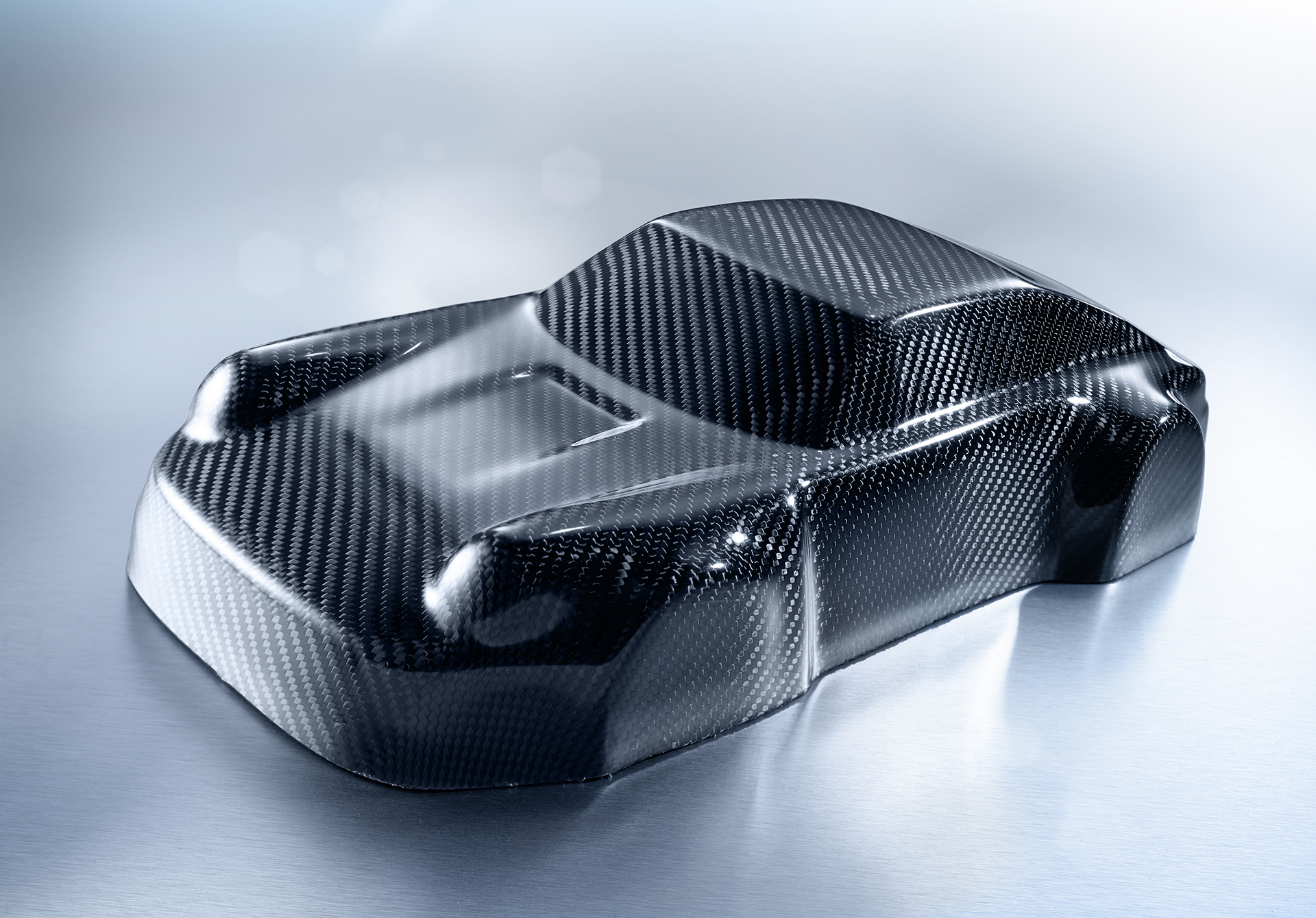

Casting Resin

Precision in every detail. RAKU® TOOL epoxy casting resin offers outstanding processability, excellent chemical resistance, and stable surfaces. Whether solid or face casting, you benefit from dimensional accuracy, adjustable pot lives, and dependable curing. Ideal for model making, jigs, foundry patterns, and prototyping using high-performance casting resin.

Epoxy Systems

Fast Cast Systems

Speed meets quality. RAKU® TOOL fast‑cast resins deliver short demolding times and high strength – perfect for prototypes, foundry models, and pattern plates. Easy to mix, fast curing, and reliable for efficient workflows.

Polyurethane Systems

Rapid Prototyping Casting Resins

Fast, precise, and short run to series production. RAKU® TOOL rapid prototyping casting resins simulate thermoplastics such as PP, PE, ABS, or rubber. Perfect for functional prototypes and small series that require high material fidelity and short development times. For designers, developers, and manufacturers who want to achieve market-ready results faster.

Polyurethane Systems

Global Support. Anytime. Anywhere.