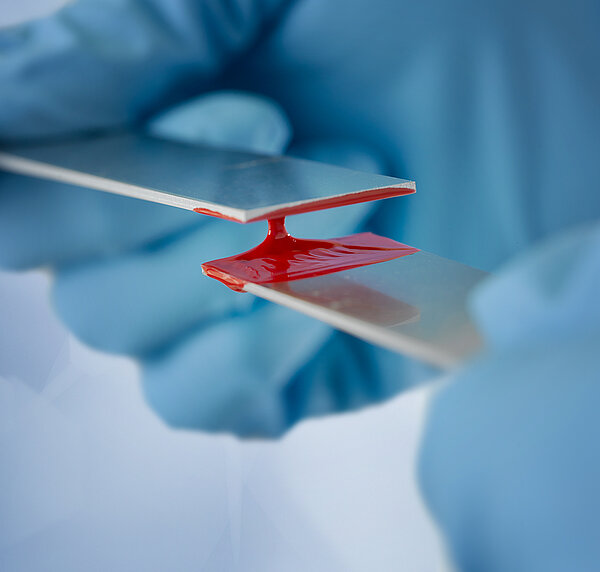

Industrial Adhesive Solutions for Strong, Lasting Bonds

Efficient, Precise, Process Reliable

RAMPF supplies industrial adhesive systems under the brands RAKU® PUR (polyurethane), RAKU® POX (epoxy), and RAKU® SIL (silicone) for durable bonding across a wide range of substrates. These adhesives deliver high strength, excellent adhesion, temperature and chemical resistance, and integrate seamlessly into both manual and automated bonding processes.

Properties and Functions

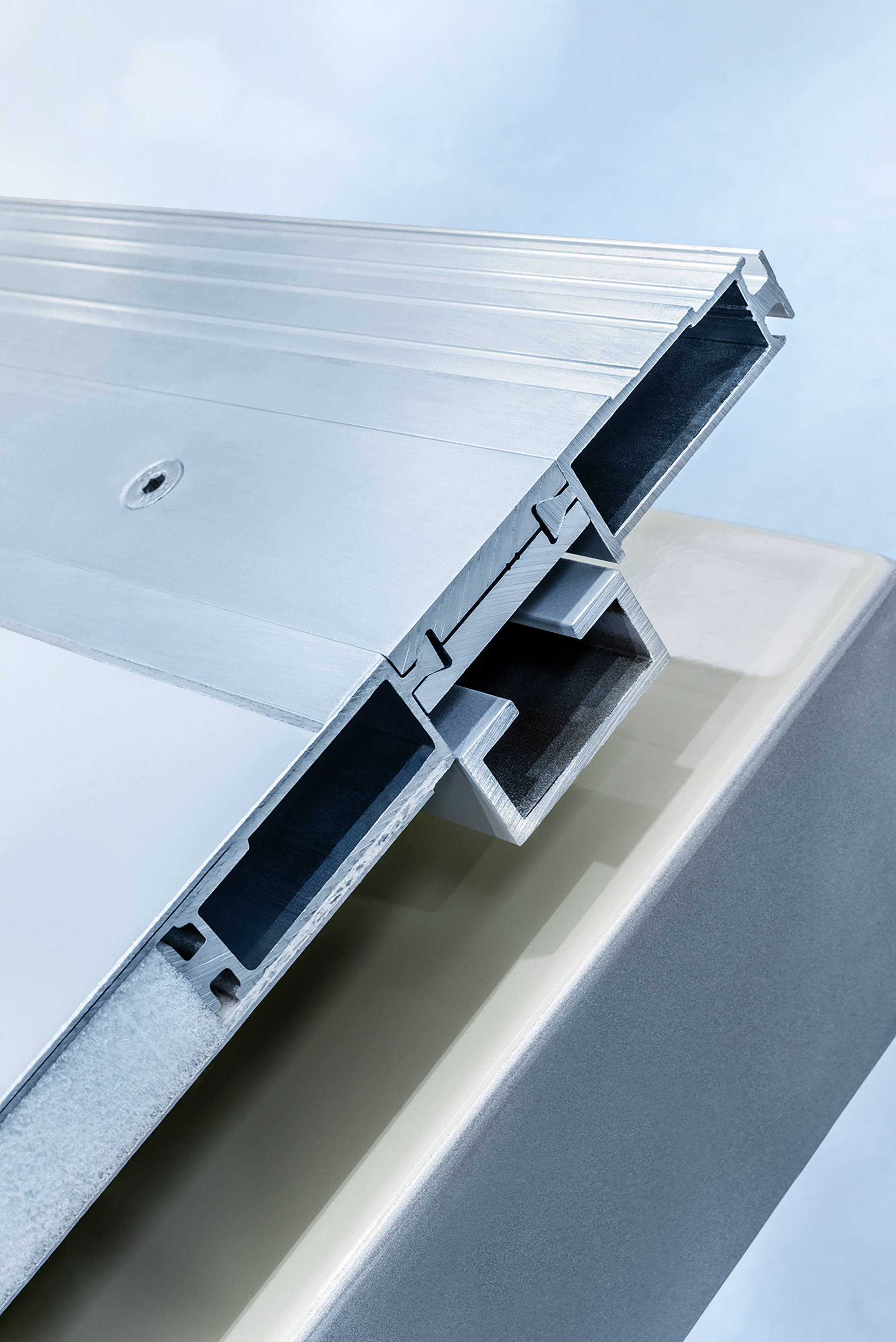

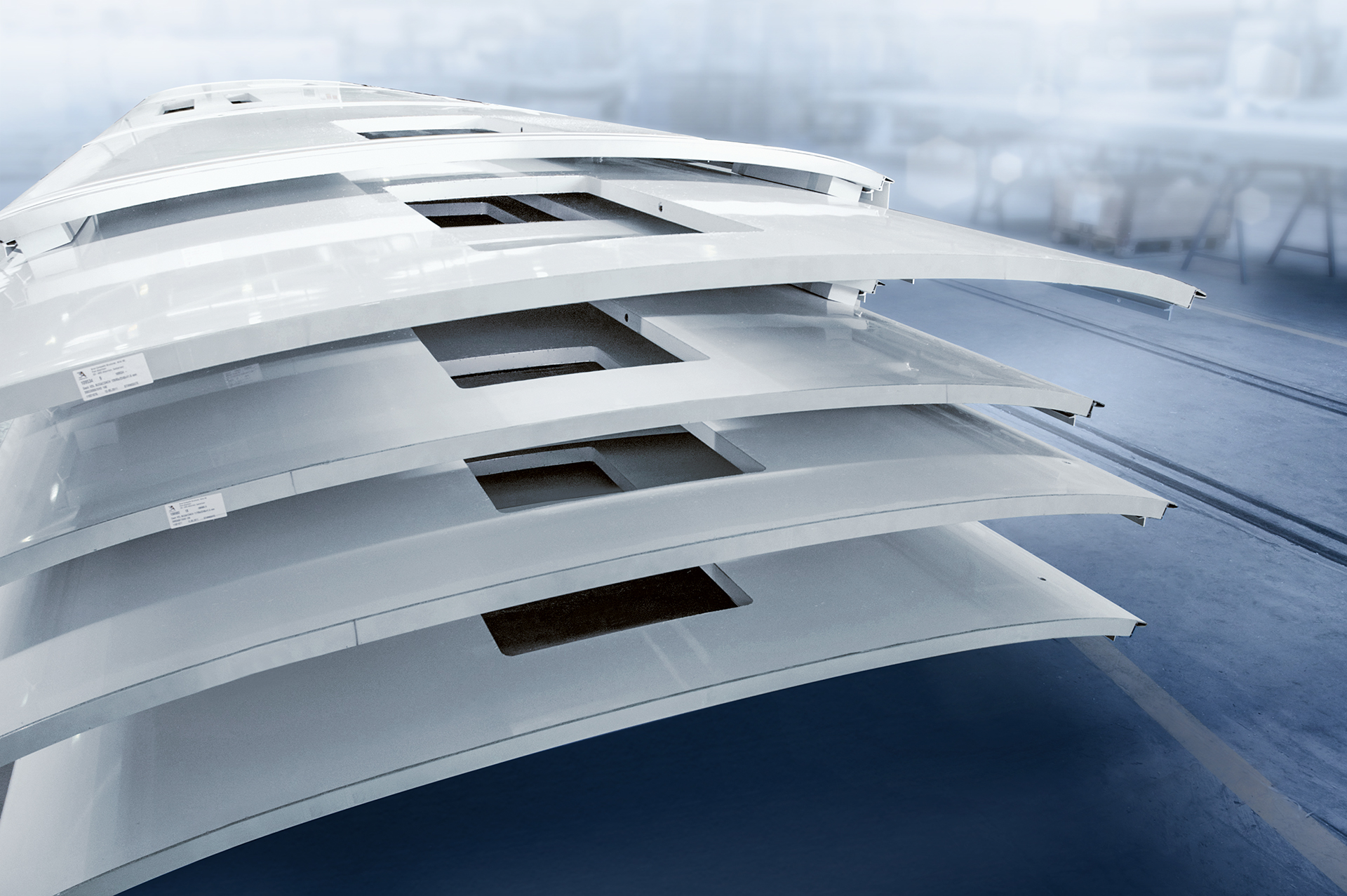

- Wide substrate compatibility: Reliable bonding with optimal adhesion on wood, plastics (including acrylic glass and Plexiglas), aluminum, metals, and mineral-based materials.

- Mechanical performance tailored to your needs: From high-strength to elastic – industrial adhesives engineered for shear, peel, and impact loads, plus NVH (Noise, Vibration, Harshness) reduction in components.

- Resistant in harsh environments: Stable strength and maximum sealing performance under temperature fluctuations, humidity, media exposure, and chemicals.

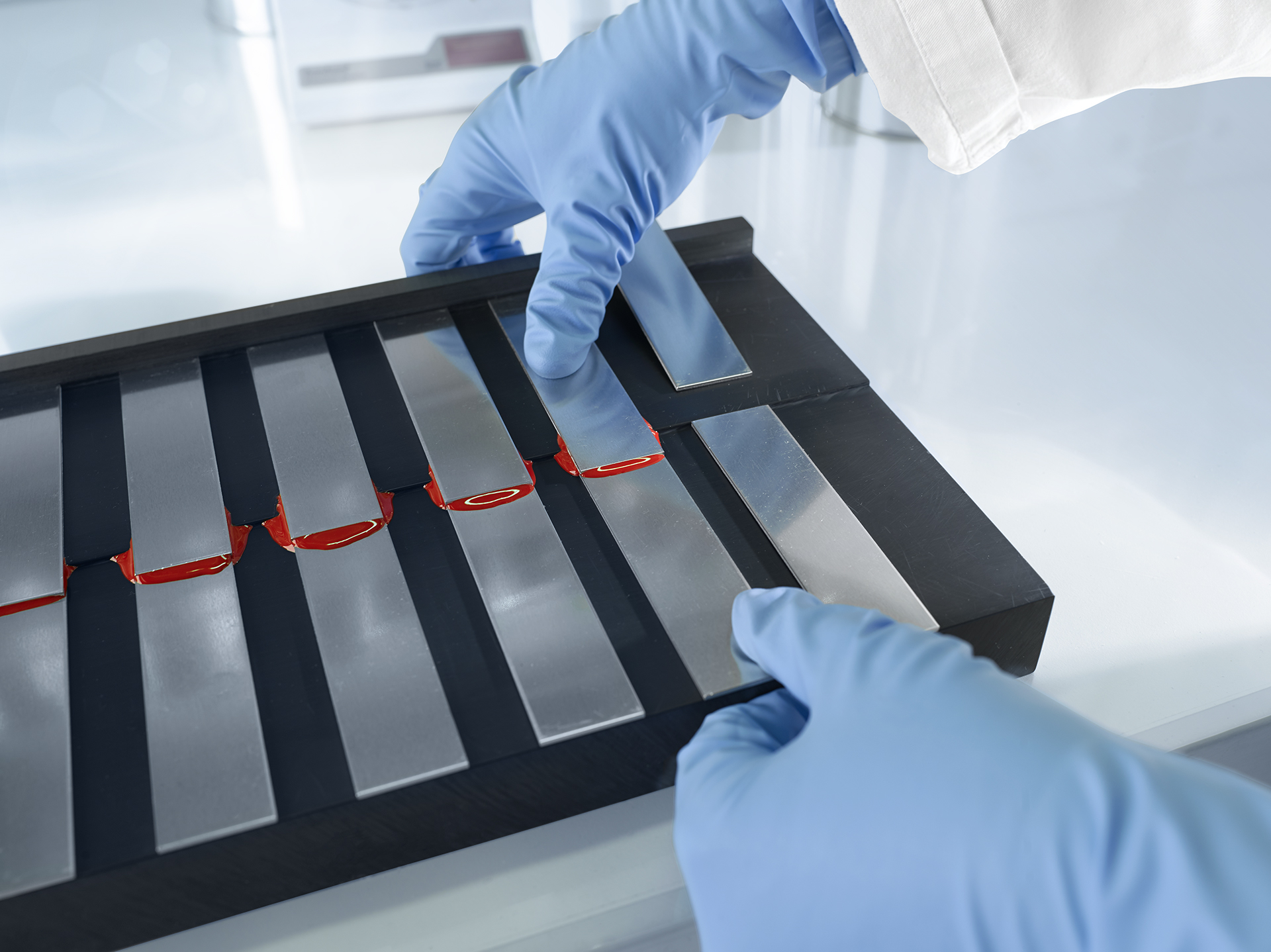

- Process‑safe dispensing: Easy handling of one‑component and two‑component industrial adhesive systems using dispensing equipment, rollers, slot dies, or manual application. Defined pot life and open time ensure repeatability and production reliability.

- Bonding and sealing combined: RAKU® SEAL sealants and structural adhesive systems in one perfectly aligned process – fewer parts, more functionality.

- Industry diversity: Automotive (interior and exterior), home appliances, wood and furniture, facade and balustrade elements, sandwich panels for buses, caravans, refrigerated vehicles, consumer electronics.

Your Key Benefits

- Application consulting and feasibility analysis: evaluation of substrates and load profiles.

- Material selection and formulation: optimized RAKU® PUR / POX / SIL systems aligned with substrates, processes, and standards.

- Prototyping and testing: tensile tests, peel tests, impact shock tests, plus climate cycling, media resistance, and long-term data.

- Surface preparation: cleaning, activating, and priming for maximum adhesion and reproducibility.

- Process design and automation with RAMPF: layout, cycle time, quality.

- Dispensing and application technology: parameter configuration for one‑component and two‑component industrial adhesive systems on machines, rollers, slot dies; inline monitoring.

- Quality assurance: documentation, traceability, series approval.

- Scaling and production ramp‑up: from lab to pilot to full series – worldwide.

- Training and support: operator training, maintenance training, and quality‑assurance training - on-site or digital.

Material Types

Low to high viscosity

Good adhesion to metal/wood and plastic

Universally applicable over medium to large areas

Rapid complete curing for short process times

Workhorse with a wide adhesive spectrum

Temperature resistance from -40 to +100 °C

Low shrinkage

High abrasion resistance

Soft elastic to very hard systems

High mechanical and chemical resistance

Certified to VDI 6022

Learn more!

Offene Zeit von wenigen Minuten bis mehrere Stunden

Elastisches Kleben und Dichten mit hoher Flexibilität (2K-Systeme: Bruchdehnung ca. 300 %, 1K > 300 %)

Extrem wasserabweisend

Universelle Haftung, auch auf Metallen

Hohe Chemikalienbeständigkeit

Höchste Temperaturbeständigkeit von -60 bis über +200 °C

Hohe UV-Stabilität

Beste physikalisch Eigenschaften nahezu konstant über den gesamten Anwendungstemperaturbereich

Mehr erfahren!

Short to long pot life, from 5 to 110 min

Exposure time of 5 to 150 min

Good adhesion to aluminum and other metals

High temperature resistance from -55 to +180 °C

Excellent chemical resistance

Cures at room temperature

Systems with rapid curing for short process times

Learn more!

Find here more information on processing diisocyanates according to REACH, Annex XVII, Entry 74:

Talk to Our Experts Now!

Let our specialists evaluate your application – complete with material recommendations, process concepts, and sample parts.

- Book an adhesive bonding trial: Realistic component tests in our technical center with full documentation.

- Request data sheets: Technical parameters, processing guidelines, approvals.

Contact us now to secure the industrial adhesive systems you need for series production and scalable growth.

Global Support. Anytime. Anywhere.