Minimal carbon footprint. Maximum vibration damping. EPUMENT® mineral casting.

Protecting the climate and the environment does not run contrary to either economic or technical interests. In fact, climate-friendly solutions are the economic basis for a sustainable future. The order of the day is to cut environmentally damaging emissions and, where possible, to avoid them completely.

After all, these emissions will be key to pricing policy and the competitiveness of products in the future. We can only reduce emissions when we know what is causing them. RAMPF Machine Systems therefore tasked an independent agency with examining EPUMENT® mineral casting and ascertaining this material’s carbon footprint.

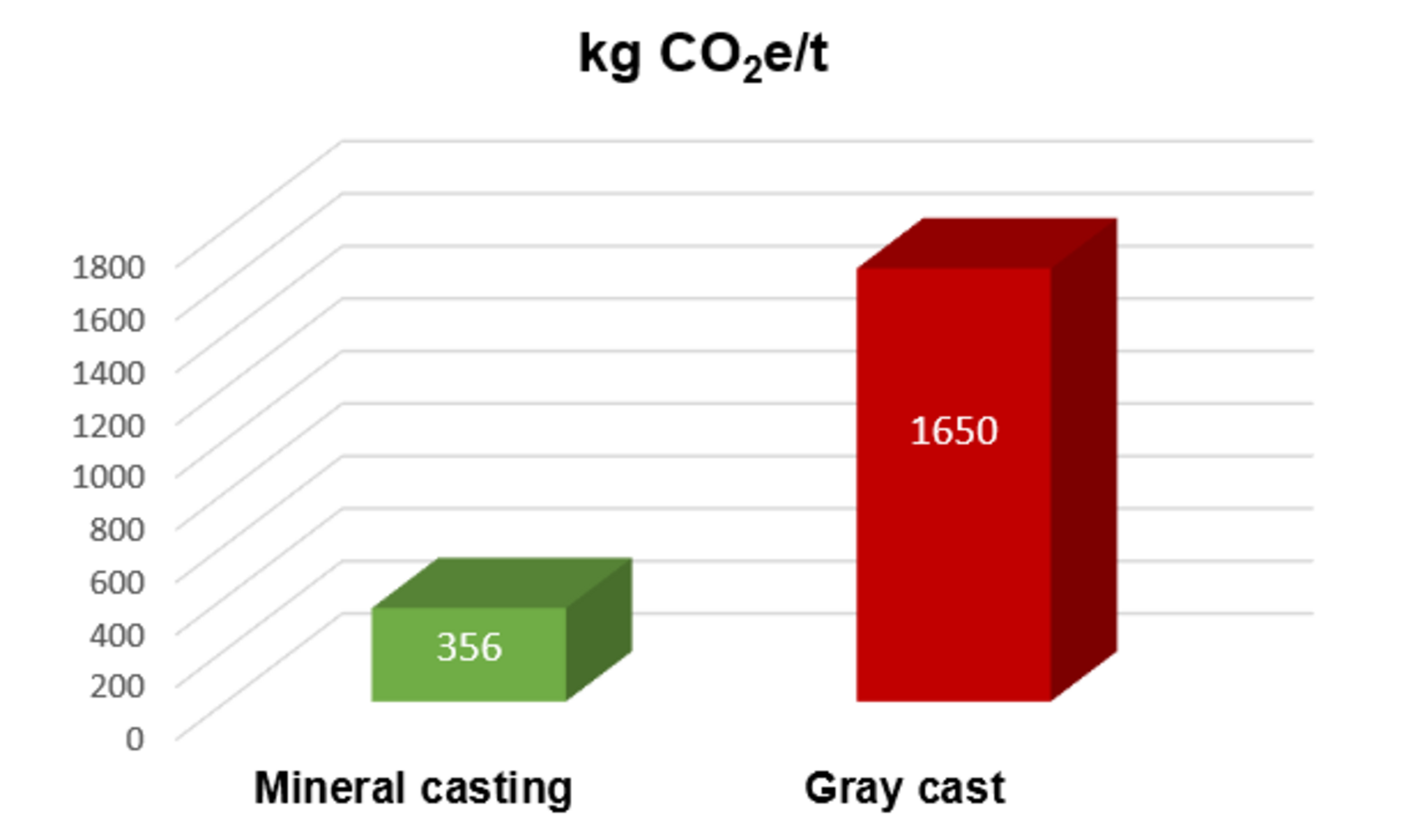

At approximately 360 kg CO2e per metric ton, the superiority of RAMPF mineral casting to other machine bed materials is abundantly clear. For example, the emissions per metric ton of mineral casting are 4.5 times lower than those per metric ton of gray cast iron!

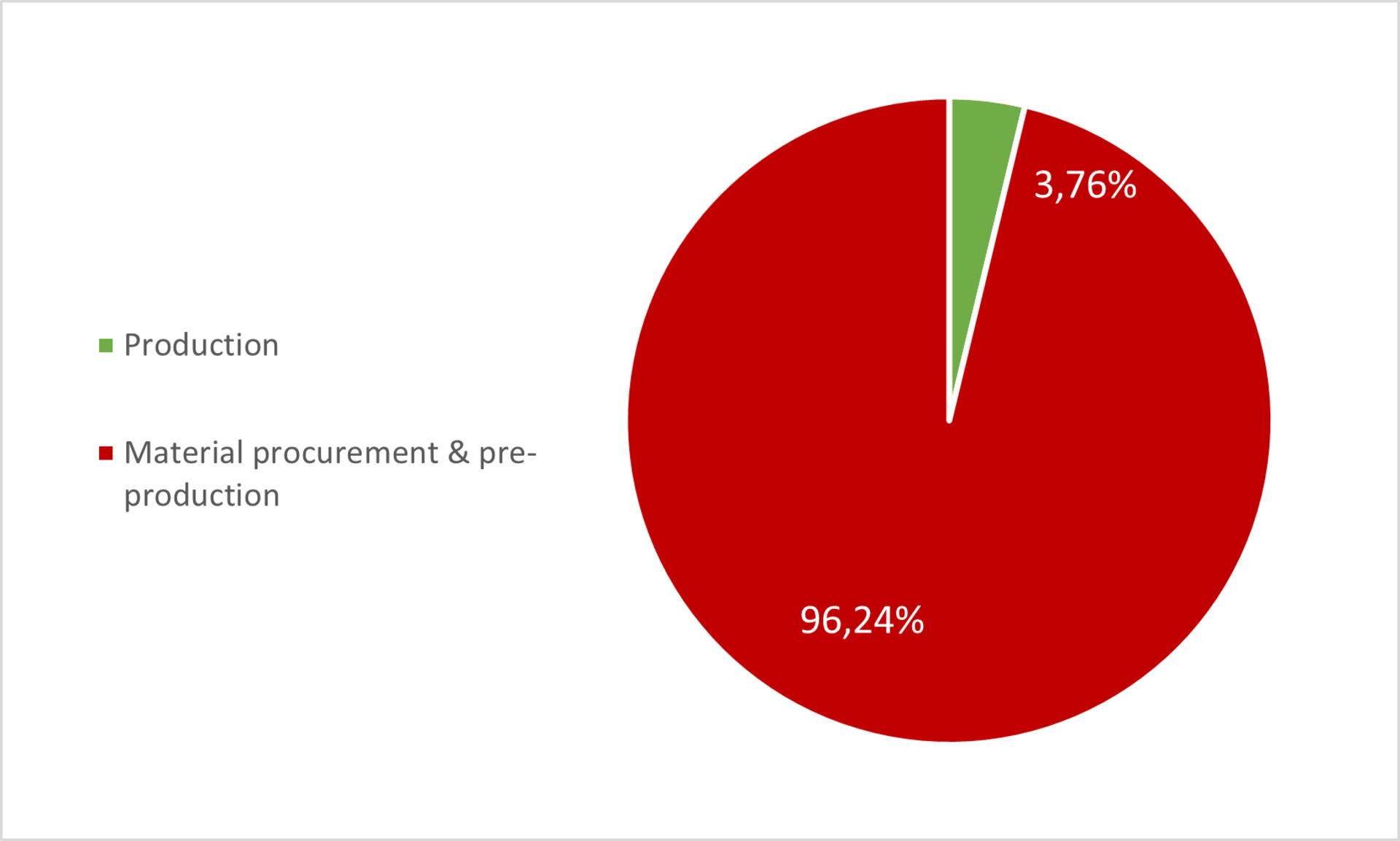

Proportion of emissions and targeted optimization

The actual manufacturing process for EPUMENT® mineral casting only accounts for just under 4 percent of the total emissions – the procurement of materials accounts for the remaining 96 percent.

This information is hugely important to RAMPF. It tells us how we can further minimize the carbon footprint of our mineral casting and make this material even more sustainable.

Accordingly, our developers are working on obtaining raw materials from renewable resources.

EPUMENT® mineral casting from RAMPF combines exceptional performance and vibration damping with outstanding eco credentials.

As a result, using mineral casting as a machine bed material significantly optimizes the carbon footprint.

Your Key Benefits

Global Support. Anytime. Anywhere.

Germany’s Supply Chain Due Diligence Act (LkSG)

Companies with 3,000 or more employees from 2023, and companies with 1,000 or more employees from 2024.

Mechanical and plant engineering companies are being indirectly called upon to improve the environmental situation throughout the entire supply chain and, in particular, to ensure greenhouse gas emissions are reduced.

Companies must carry out comprehensive risk analyses to avoid fines under the LkSG and negative media coverage. To meet their duty of care, companies should set absolute CO2 reduction targets and not exceed these. Choosing only to offset emissions is viewed with criticism.

In the long term, a direct obligation based on the European Commission’s Corporate Sustainability Reporting Directive (CSRD) will be imposed. This envisages even more stringent rules for sustainability reporting.

EPUMENT® mineral casting is a good alternative to metallic materials. It can significantly reduce the carbon footprint of your machine, while also improving its technical features.

By switching to mineral casting from RAMPF, you are making an important contribution to protecting our environment and putting yourself in an excellent position to take further measures relating to climate-neutral production.

It goes without saying that our development team will be more than happy to help you with the design and the switchover from your current setup.