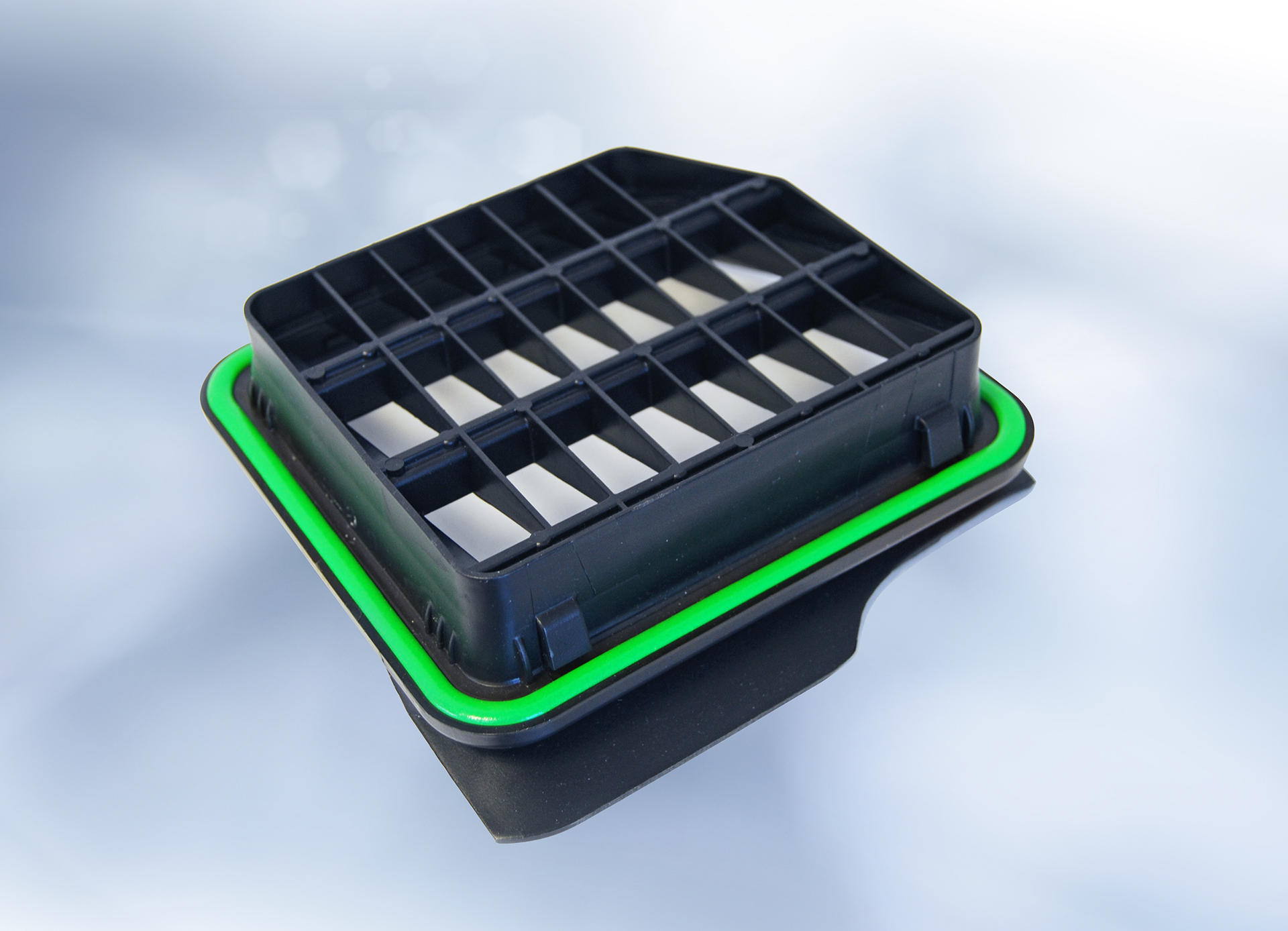

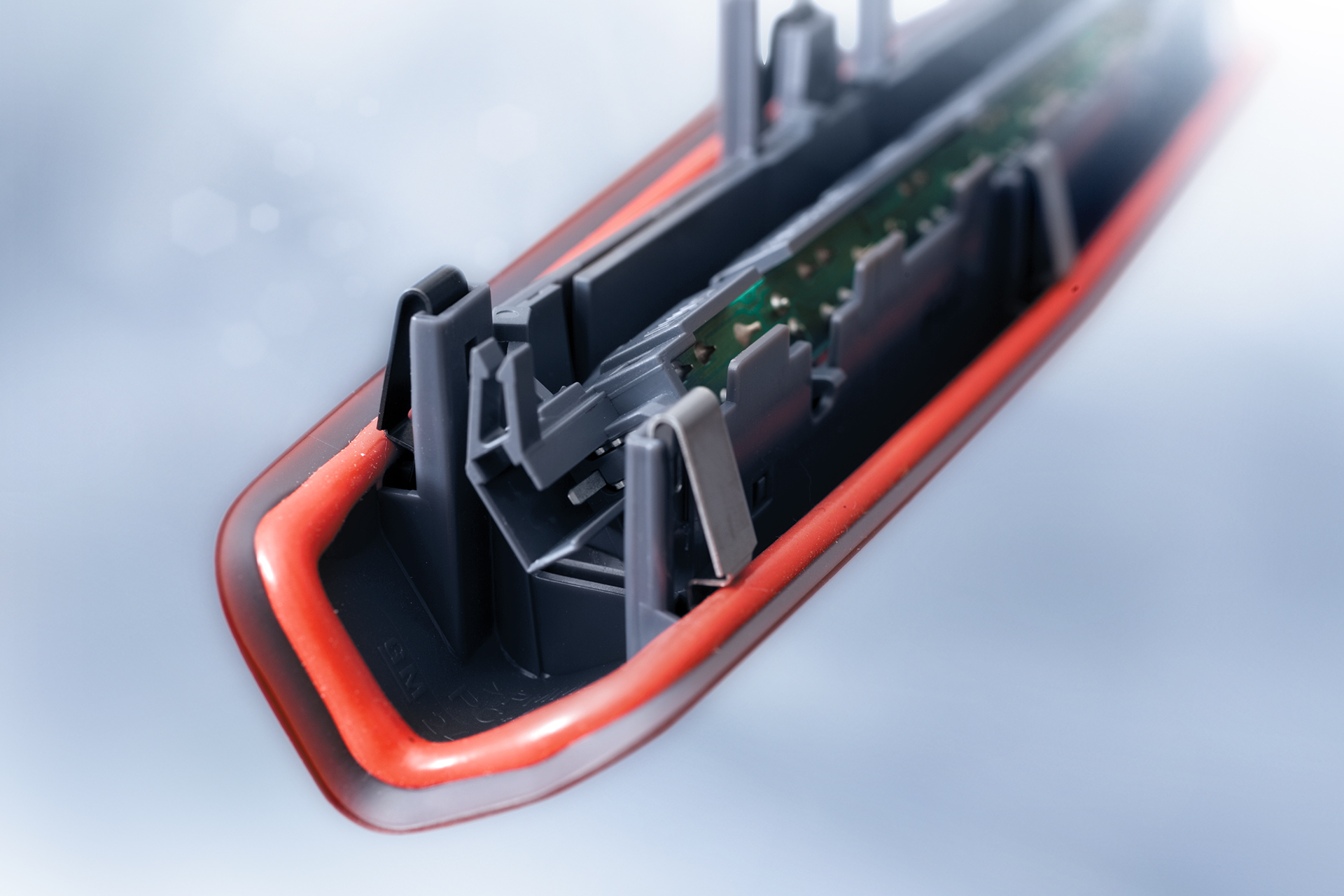

Sealing Foam

For Maximum Tightness and Efficiency

Our sealing foam and elastomer gaskets based on polyurethane and silicone reliably protect your components against moisture, dust, and chemical exposure. Applied directly using state-of-the-art FIPFG and FIPG technology, the foam seal ensures perfect adhesion, fast processing, and long-term durability. Benefit from custom-engineered sealing systems that accelerate your production processes and consistently safeguard product quality.

Properties and Functions

- Perfect Fit: The sealing foam adapts precisely to the geometry of your component.

- Exceptional Resistance: Reliable protection against moisture, chemicals, dust, and extreme temperatures, including standards such as UL94 V0 and FMVSS302.

- Automated Processing: The sealing foam is applied in a highly precise, process-stable system, ensuring consistently high quality at high cycle rates and large production volumes.

- Material Versatility: Polyurethane foam or silicone foam for every requirement, plus customized elastomer gaskets.

Your Key Benefits

Materialtyps

Area of application

Temperature resistance, long-term: from -40 to +100°C; short-term: +140°C

Chemical resistance to fats and oils, detergents, aqueous solutions, etc.

Properties

Outstanding physical properties such as compression set, tensile strength, elongation at break, etc.

Low water absorption

UV-resistant formulations possible

Adhesion

Excellent adhesion to a wide variety of substrates

Coordinated pre-treatment systems available

Structure

Compression rate: 30 – 60%

Flame retardancy

UL 94, FMVSS 302

Mehr erfahren!

Area of application

Temperature resistance, long-term: from -60 to +200 °C; short-term: +300 °C

Exceptional chemical resistance for extreme environments

Properties

Optimum physical properties such as compression set across the entire application temperature range

Extremely water-repellent

Excellent UV resistance

Adhesion

Outstanding adhesion to a wide variety of substrates

With pre-treatment if necessary

Structure

Compression rate: 10 – 30%

Flame retardancy

UL 94. FMVSS 302

Mehr erfahren!

Find here more information on processing diisocyanates according to REACH, Annex XVII, Entry 74:

Global Support. Anytime. Anywhere.