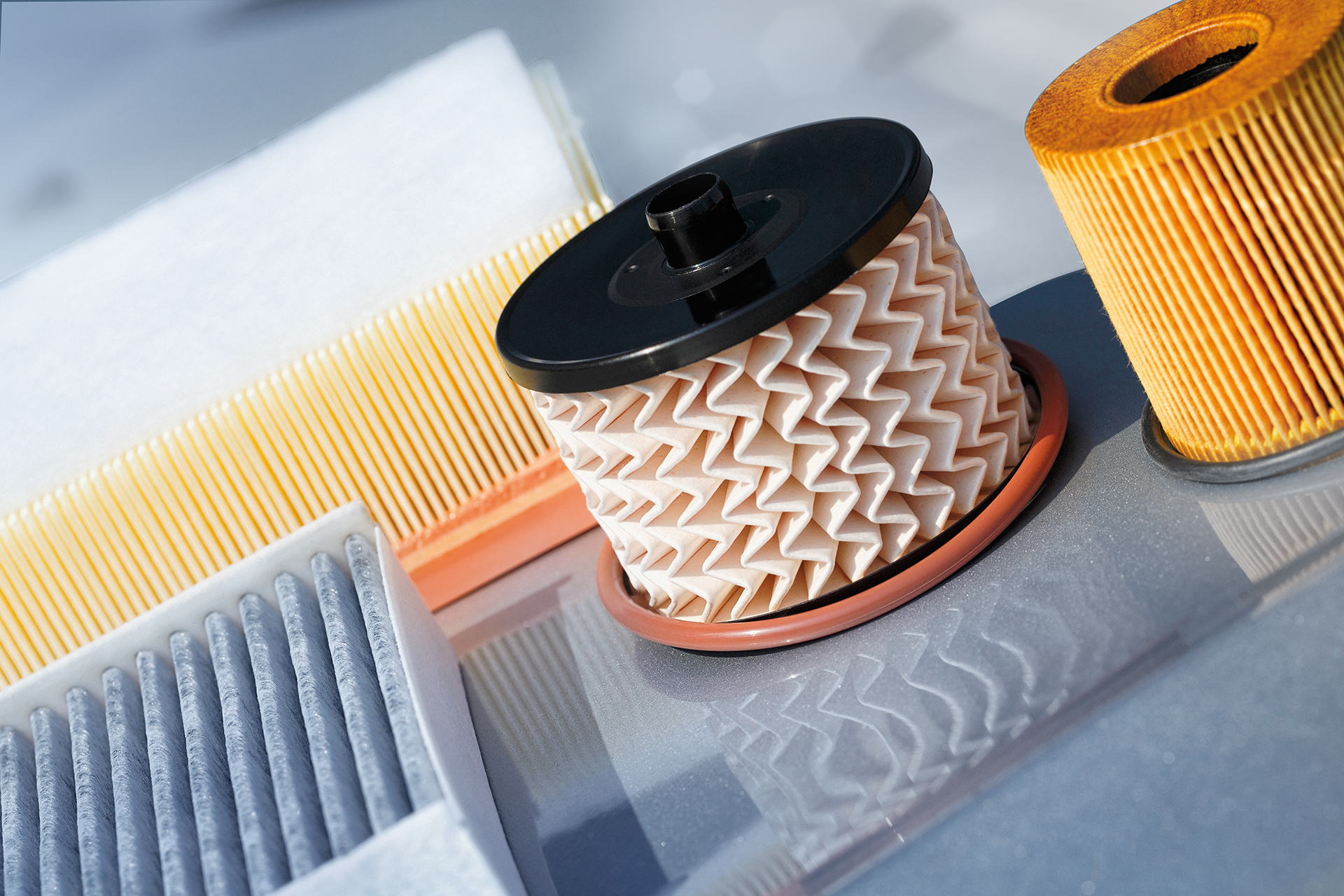

Adhesive and Sealant

For Robust, Long Lasting Bonds

Bonding is the key technology of the 21st century – efficient, flexible, and highly reliable. With our innovative adhesive and sealant solutions, you can permanently bond a wide range of materials while reducing costs through automated processes. Whether automotive, furniture, electronics, or building supply industries – our industrial adhesives deliver outstanding strength, temperature resistance, and chemical durability, plus excellent adhesion on various substrates. Rely on solutions that optimize your production and ensure your components are permanently bonded.

Properties of Our Adhesive and Sealant

- High strength and adhesion: Secure bonding of substrates such as wood, plastics, metal, glass, and more; RAMPF recommends prior adhesion testing on the intended materials.

- Temperature and chemical resistance: Reliable also under extreme conditions

- Flexible processing: Compatible with manual and automated applications

- Broad portfolio: One-component and two-component polyurethane, epoxy, and silicone systems; one-component and two-component silane-modified polymers (SMP) for specialized requirements

Material Types

Low to high viscosity

Good adhesion to metal/wood and plastic

Universally applicable over medium to large areas

Rapid complete curing for short process times

Workhorse with a wide adhesive spectrum

Temperature resistance from -40 to +100 °C

Low shrinkage

High abrasion resistance

Soft elastic to very hard systems

High mechanical and chemical resistance

Certified to VDI 6022

Learn more!

Exposure time from a few minutes to several hours

Highly flexible elastic bonding and sealing (elongation at break for 2C systems: approx. 300%; 1K > 300%)

Extremely water-repellent

Universal adhesion, also to metals

Excellent chemical resistance

Outstanding temperature resistance from -60 to over +200 °C

High UV stability

Optimum physical properties, virtually constant over the entire application temperature range

Learn more!

Short to long pot life, from 5 to 110 min

Exposure time of 5 to 150 min

Good adhesion to aluminum and other metals

High temperature resistance from -55 to +180 °C

Excellent chemical resistance

Cures at room temperature

Systems with rapid curing for short process times

Learn more!

Strong adhesion, reliable sealing performance, and high formulation flexibility:

Tailor‑made silane‑modified polymers from RAMPF stand for maximum performance and quality in machine and metal engineering, building technology, the automotive and transportation sectors, the white‑goods industry, marine applications, and construction.

Find here more information on processing diisocyanates according to REACH, Annex XVII, Entry 74:

Global Support. Anytime. Anywhere.