Mixing and Dispensing Systems C-DS / C-DS+

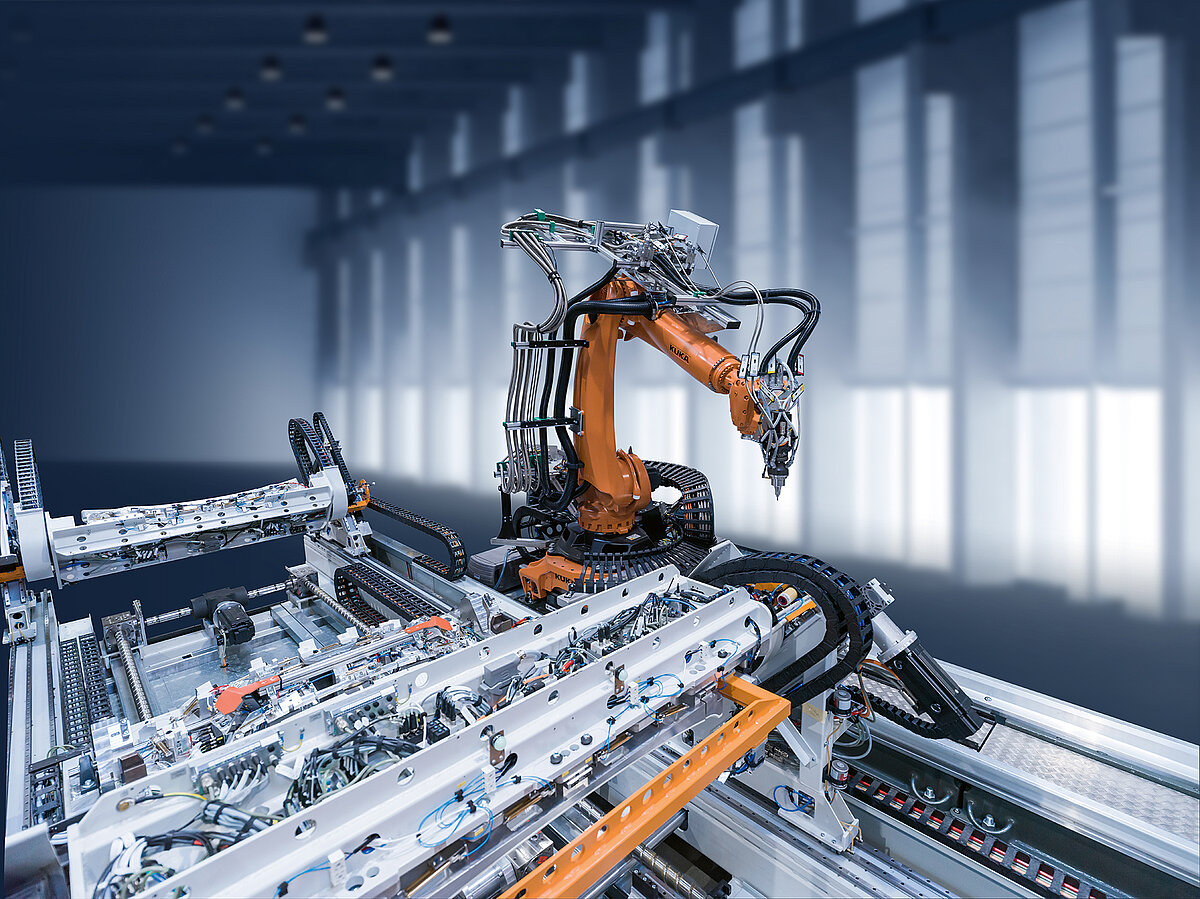

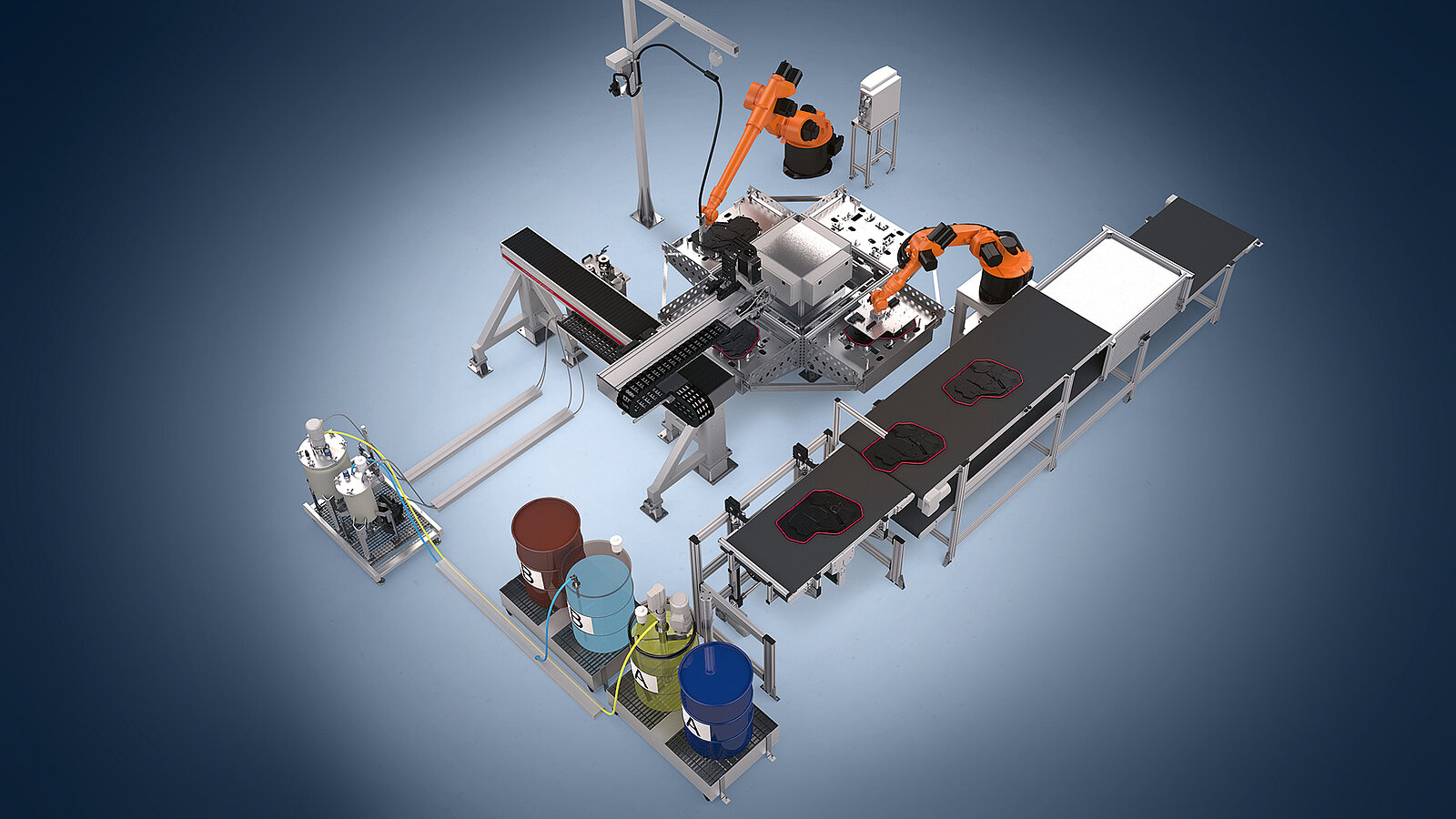

Versatile use - from manual workstations to semi automated setups and fully automated robotic systems.

Mixing and Dispensing Systems

For reliable sealing, potting, bonding, and heat conducting applications

Our mixing and dispensing systems deliver precision for sealing, potting, bonding, and thermal management - also under complex production requirements. With advanced dosing technology and fully automated solutions, we ensure maximum process reliability and efficiency. Whether you work with one‑component or multi‑component materials, we design custom systems that keep your production future‑ready. Optimized for performance, accuracy, and flexibility.

Rotary table with component

Component pre-treatment

Component handling

Conveyor belt

Dispensing

Material circulation

Day tank

Material preparation

Supply container

Barrel transfer station

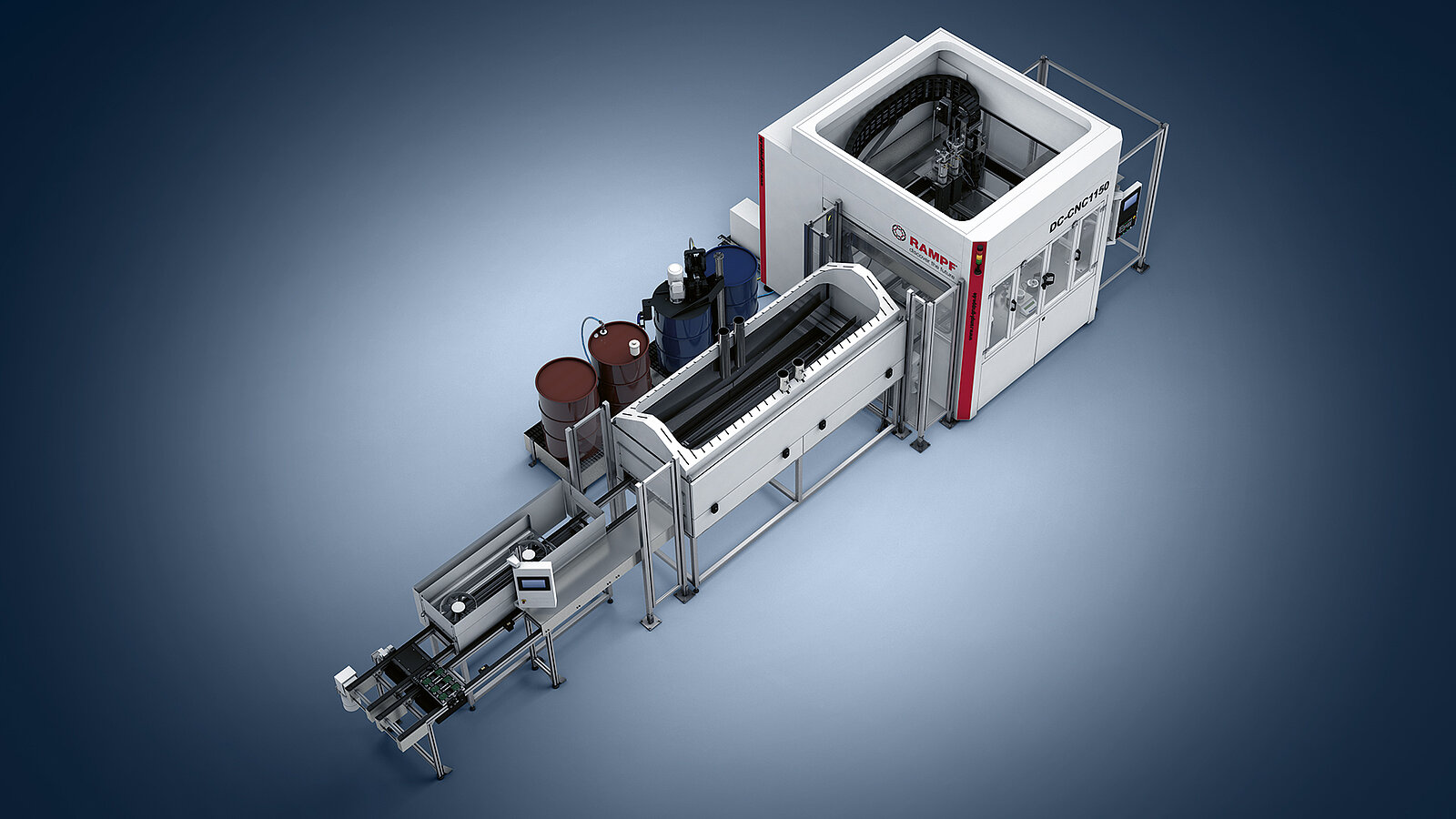

Day tank

Material preparation

Material circulation

Component inspection

Delivery container

Barrel transfer station

Conveyor belt

Component handling

Component pre-treatment

Component post-treatment

Pre-casting

Degassing

Final layer casting

Global Support. Anytime. Anywhere.