Precision Grinding for Ultimate Accuracy

High Level Contract Grinding for Machine Components

RAMPF delivers a fully integrated service approach centered around advanced Precision Grinding for highly accurate machine and plant components. With a climate‑controlled precision grinding center, powerful grinding machines, and over 35 years of expertise, we manufacture flawless parts—from surface grinding to guideway grinding. Precision, speed, and technical mastery combine into a grinding process that consistently exceeds your quality expectations.

Highest Precision for Demanding Components

- Comprehensive grinding expertise: From grind‑optimized design and tooling development to final assembly, RAMPF supports every step of your Precision Grinding workflow. The result: maximum accuracy and consistent, repeatable quality.

- Advanced grinding machines for complex requirements: CNC and NC precision grinders for components up to 25 tons, ultra‑accurate guideways, and large machine beds. All grinding bodies operate with minimal vibration for stable processes and superior surfaces.

- Versatile manufacturing capabilities: Whether grinding, lapping, measuring, or assembly—our combination of state‑of‑the‑art equipment and experienced specialists ensures premium precision across all materials, including mineral casting, hard rock, steel, cast iron, and ceramics.

Your Key Benefits

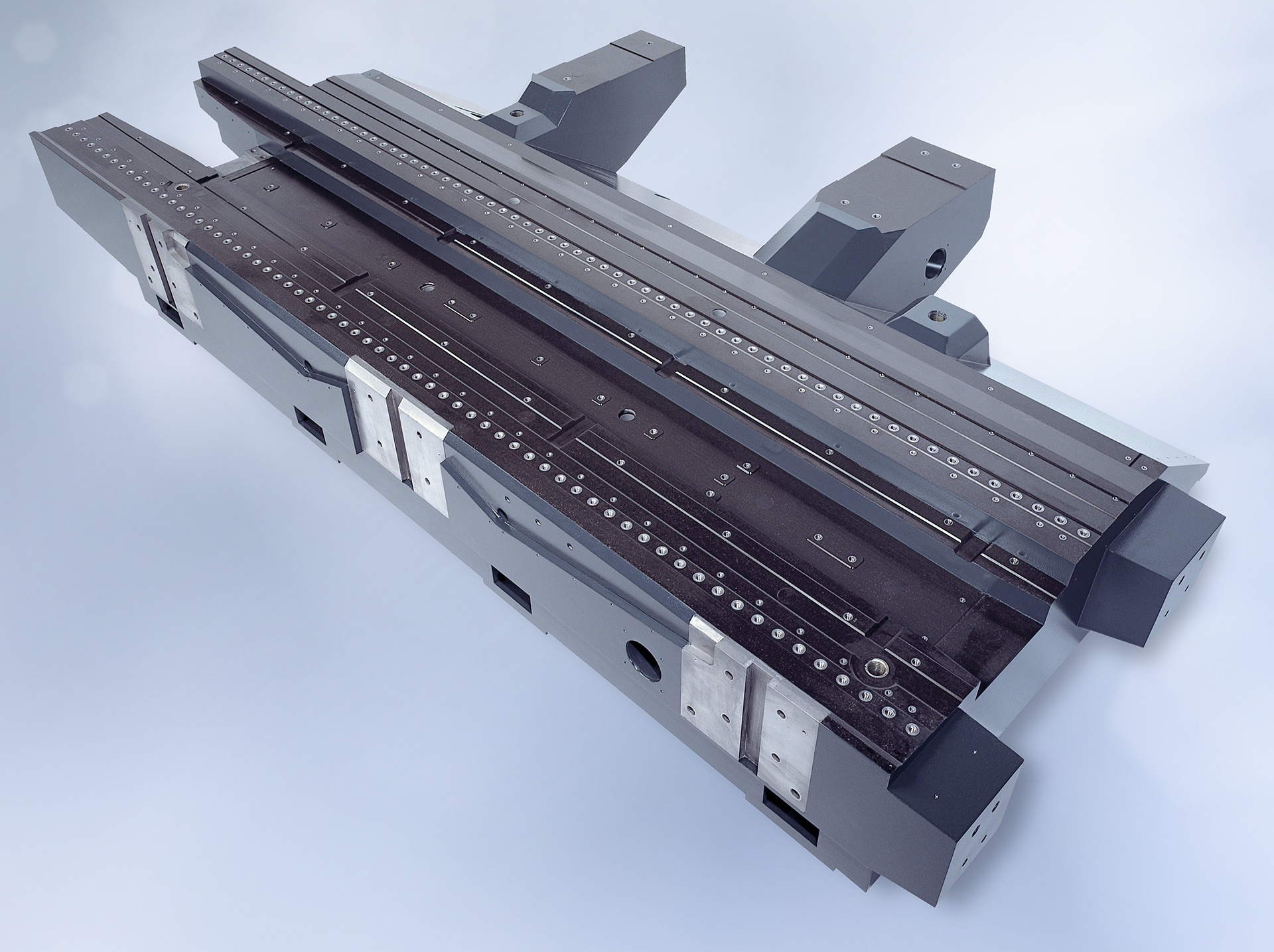

- Surface & guideway grinding: Dimensional and geometrical accuracy for machine beds, frame components, and precision guideways.

- Lapping of functional surfaces: Ultra‑fine finishes for maximum precision and minimal friction.

- Grinding of diverse materials: Machining of steel, cast iron, mineral cast, hard rock, CFRP, ceramics, and more.

Manufacturing and precision grinding of vibration-damping machine beds and machine bed components made of mineral casting. Configuration into system solutions through subsequent assembly, joining, and testing processes.

Flat grinding and guideway grinding for metal machine components with various alloys, tempering and hardness levels, and coatings. Refurbishing or reworking of large components. Flat grinding and guideway grinding for metal machine components with various alloys, tempering and hardness levels, and coatings. Refurbishing or reworking of large components.

End-to-end manufacture of high-precision components for measuring and specialized mechanical engineering made from hard stone, including joining (bonding, screwing), and precision assembly of add-on components.

- Working area LxWxH: 5,000 x 2,000 x 1,350 mm

Max. workpiece weight: 15 metric tons

Equipment

- Universal grinding, drilling, and milling head: 180° swivel range; Pitch 1°

- Hydraulic and electromechanical drive

- Switching accuracy 10 μm

Sinumerik 840 D control system

Extras

- Grinding wheel diameter 700 mm

- Angle, wedge, convex, and concave grinding functions

- Automatic balancing unit and truing device

- Working area LxWxH: 7,000 x 2,650 x 2,000 mm

Max. workpiece weight: 25 metric tons

Equipment

- Universal grinding, drilling, and milling head: 180° swivel range; Pitch 1°

- Hydrostatic table bearing

Sinumerik 840 D control system

Extras

- Grinding wheel diameter 700 mm

- Angle, wedge, convex, and concave grinding functions

- Automatic balancing unit and truing device

Global Support. Anytime. Anywhere.