Your Dosing System Partner

For Maximum Efficiency and Process Reliability

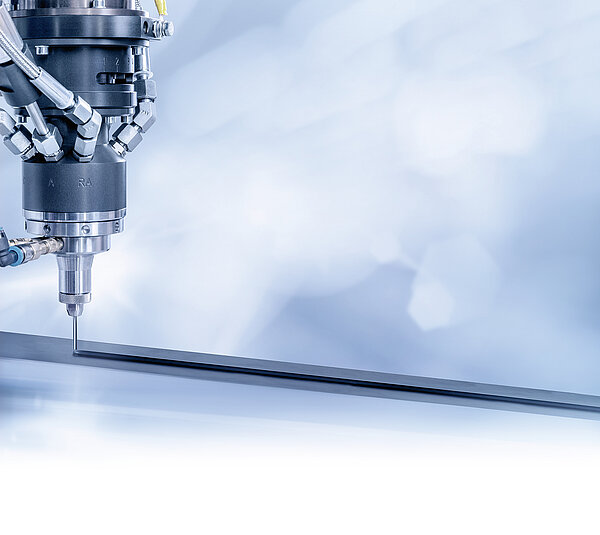

As a leading Dosing System manufacturer, we develop customized solutions for precise mixing, filling, and metering of single-component and multi‑component reactive plastics. Whether polyurethane, epoxy, or silicone: our systems deliver accuracy, process stability, and efficiency. From compact mixing and dosing systems to high‑performance industrial units, our technology optimizes your workflow and ensures consistent product quality.

Properties and Functions of Our Dosing Systems

- Precise mixing technology: Dynamic, static, and dynamic‑static mixing systems for high‑viscosity, abrasive, and shear‑sensitive materials.

- Flexible metering technology: Metering pumps, displacement pumps, and vacuum drum presses for variable output and bubble‑free processing.

- Durable components: Stainless‑steel mixing chambers, premium metering valves, ceramic valve technology, and wear‑resistant coatings for maximum lifetime.

Your Key Benefits

Dynamic

With servo‑driven ceramic valve technology, the MS‑C sets new standards in reproducibility. The separation of valve and mixing chamber levels makes the system extremely maintenance‑friendly.

Models:

- MS‑C 76 – 0.1–2 g/s, flexible for reactive materials

- MS‑C 100 – 2–120 g/s, various mixing chamber geometries available

The MK system is deployed used thousands of times worldwide and stands for reproducible, clean metering with pneumatically controlled needle‑seat valves. Stainless‑steel chambers, temperature‑controlled options, and advanced sealing ensure consistent results.

Models:

- MK 107 – 1–10 g/s, up to 3 component valves plus purge and air valves

- MK 108/111 – 0.01–1.5 g/s, compact for ultra‑precise small shot applications

- MK 200 – 5–200 g/s, ideal for pasty adhesives, industrial pastes, and shear‑sensitive materials

Static

Reliable for High Viscosity and Abrasion

Models:

- MS‑S – for pasty materials, pressure‑resistant disposable mixers, clean thread break

- MS‑SC – membrane valves for highly abrasive media, no moving parts in contact with the material

MS-SC mini

Static-Dynamic

The MSC–SD combines static and dynamic mixing in an autonomous system, enabling maximum efficiency and flexibility through automatic mixing chamber exchange.

The patented MS‑C technology in the drive module ensures the highest level of process stability.

Delivers consistent dosing—independent of fillers or viscosity.

Advantages:

- Variable volumes and cycle times

- Multiple chamber sizes

- Efficient, intelligent drive system

Ideal for medium‑ to high‑viscosity materials and fast material changes.

Advantages:

- Bubble‑free bonding and sealing

- Maximum material utilization

- Increased process stability

Perfect for dosing units handling low‑abrasive fillers. Optimized tooth geometry and coatings extend service life.

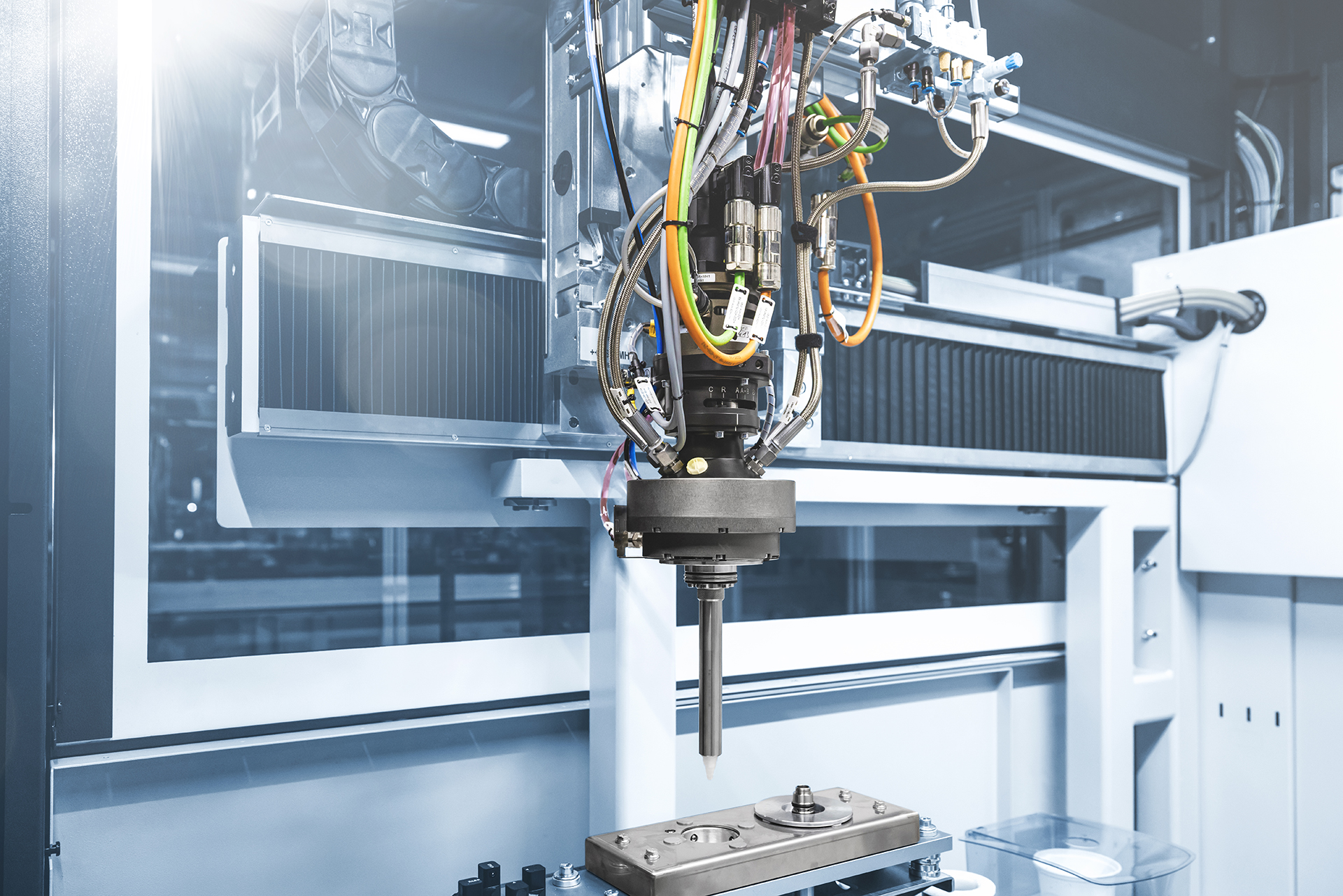

We are the market leader for high-performance, low-maintenance process technology for sealing, casting, and bonding a wide variety of polymer systems. We know that every production process places unique requirements on a dispensing system’s components. By precisely coordinating material transport and preparation systems, mixing technology, and dispensing solutions, we ensure perfect dispensing results.

Your Benefits

- Dynamic mixing technology for optimum reactivity of materials with different viscosities

- Reliable production thanks to standardized process technology integrated into a holistic solution

- You benefit from the experience we have gained from over 3,300 projects

HMI user interface for optimum connectivity and user guidance

We use controllers from Siemens and Beckhoff to optimize the efficiency, speed, and reliability of our dispensing systems and robots. Thanks to the newly developed RAMPF HMI, our customers also have a universal user interface at their disposal. This ensures platform-independent connectivity with all common mobile devices and allows for a universally adapted visualization for ease of use. The small number of user levels makes for a simple, intuitive, and easy-to-navigate operating concept.

Your Benefits

- One partner for the entire automation process

- Standardized graphical user interface for easy use and quick maintenance

- Installation and maintenance with certified service staff – worldwide

Global Support. Anytime. Anywhere.