Efficient Dispensing Processes

For Precision Bonding, Sealing, and Potting

Our innovative dispensing processes ensure precise bonding, sealing, and potting of single‑component and multi‑component reactive resin systems. With more than 3,300 completed projects worldwide, we deliver tailored solutions, maximum process reliability, and top‑tier efficiency. From electronics and automotive to industrial manufacturing, our advanced dosing technologies elevate your production to the next level with highly accurate, automated dispensing technology.

Properties and Functions

- Integrated dispensing processes for customized production systems

- Turnkey systems with unified user interface and data management

- Surface activation and measurement technology for secure, stable production

- Modern HMI architecture for intuitive control and transparent process states

- Flexible systems with fast product changeovers

Your Key Benefits

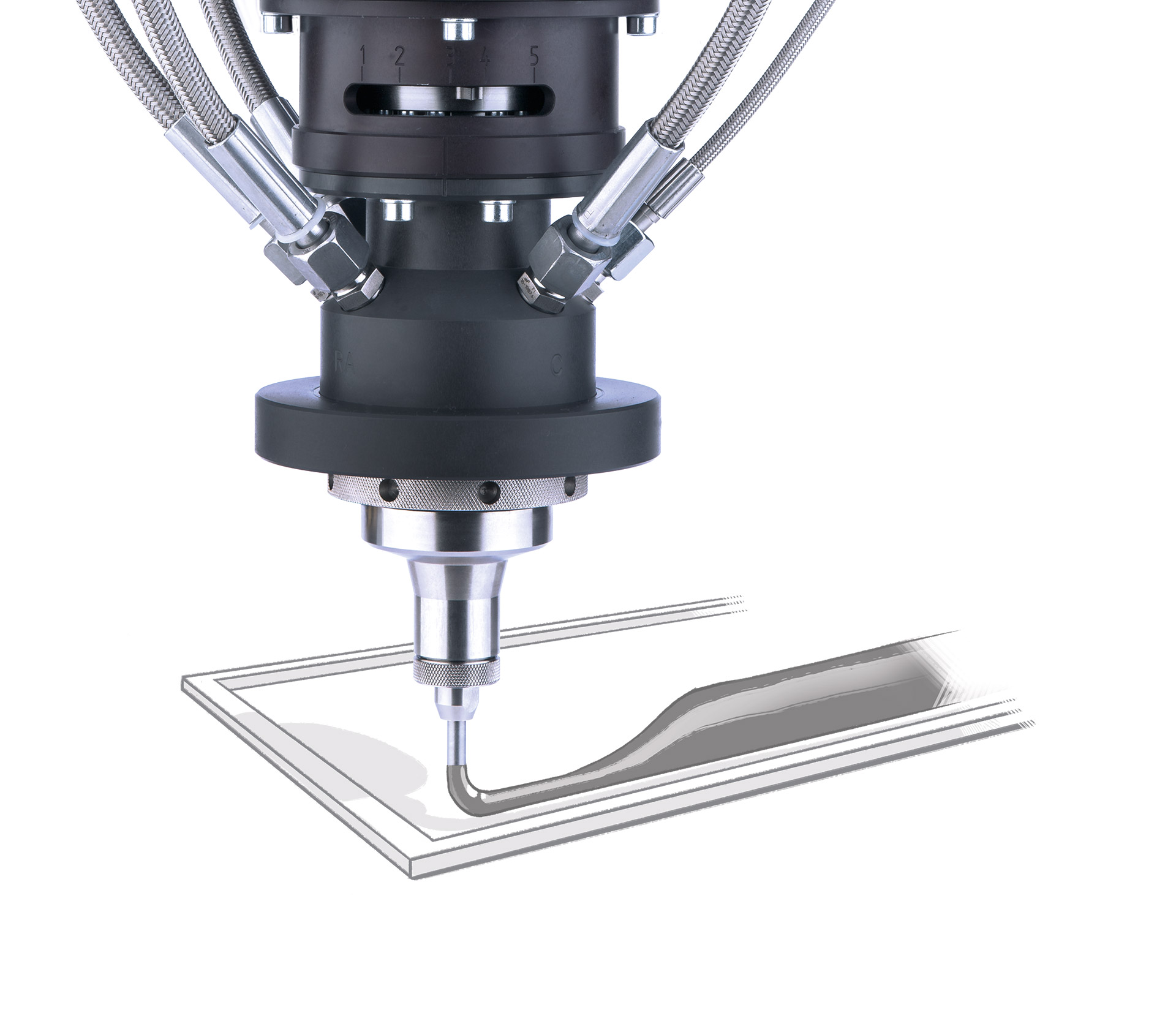

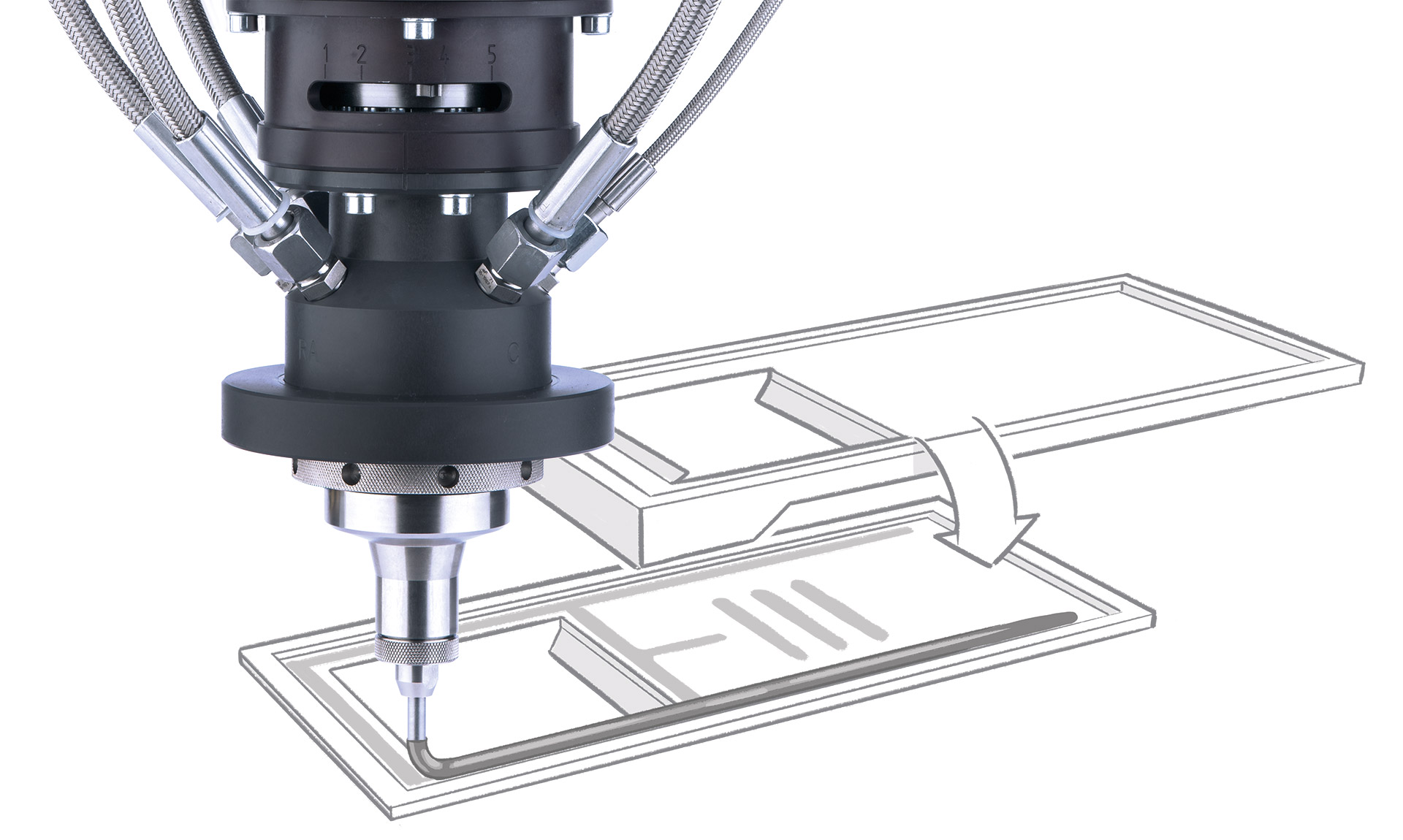

Sealing

We process multi-component reactive polyurethane and silicone foams into sealants. Multi-axis robots apply these to level and curved surfaces fully automatically. After curing, a seamless gasket (formed in place foam gasket = FIPFG) is bonded to the component and provides static protection against dust and moisture. The foams can also be dispensed into a carrier mold and processed further as a custom-fit, cured gasket (molded foam).

VALUE ADDED

- Maximum productivity thanks to customerspecific system design

- Consistent material quality thanks to regulated air load

- Low-maintenance dynamic mixing technology

With dispensing technology and robot-assisted automation solutions, sealing beads made of polyurethane and silicone are applied to a wide variety of components. The elastomers can be applied to flat and curved surfaces. After curing, a non-detachable, elastic gasket (formed in place gasket = FIPG) is bonded to the component and provides static protection against dust and moisture. Flexible production systems with surface activation for improving adhesion, heat treatment, and quality monitoring ensure optimum production results.

VALUE ADDED

- Consistent material quality through dynamic or static mixing processes

- Precise overlapping points thanks to displacement-free shut-off technology

- Integrated systems for improving adhesion, rapid curing, and leakage testing

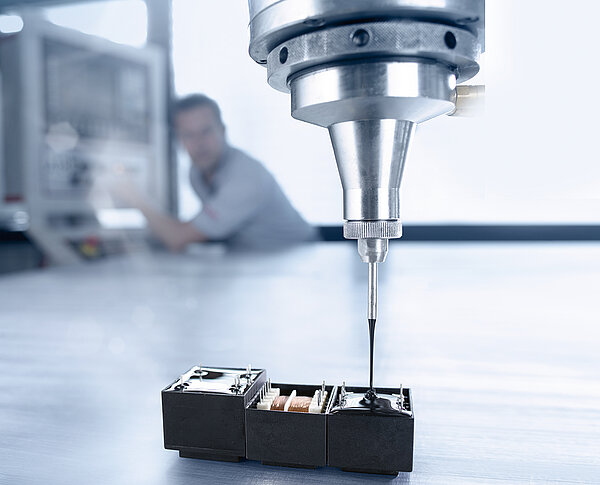

Casting

Sensitive electronic assemblies are permanently protected from contact, moisture, and damage through single-stage or multi-stage casting process, whereby usually two-component casting materials based on polyurethane, silicone, or epoxy resin are used to reliably embed the components. A highly effective material preparation unit for air degassing ensures a bubble-free casting process.

Added value

- Reliable insulation and protection of components through casting materials with different viscosities and densities

- Process reliability through low-maintenance static or dynamic mixing technology with perfectly coordinated dispensing pumps and material preparation

- Short cycle times and exceptional quality results thanks to automation concepts developed by RAMPF

Electronic components with windings, narrow gaps, or shapes that are difficult to vent are cast without air bubbles in a vacuum. The components meet the highest insulation requirements and continue to deliver maximum performance under extreme conditions. The vacuum technology is also used for producing optically transparent connections (e.g. for manufacturing displays).

Added value

- Reliable insulation and protection of components through casting materials with different viscosities and densities

- Process reliability through low-maintenance static or dynamic mixing technology with perfectly coordinated dispensing pumps and material preparation

- Short cycle times and exceptional quality results thanks to automation concepts developed by RAMPF

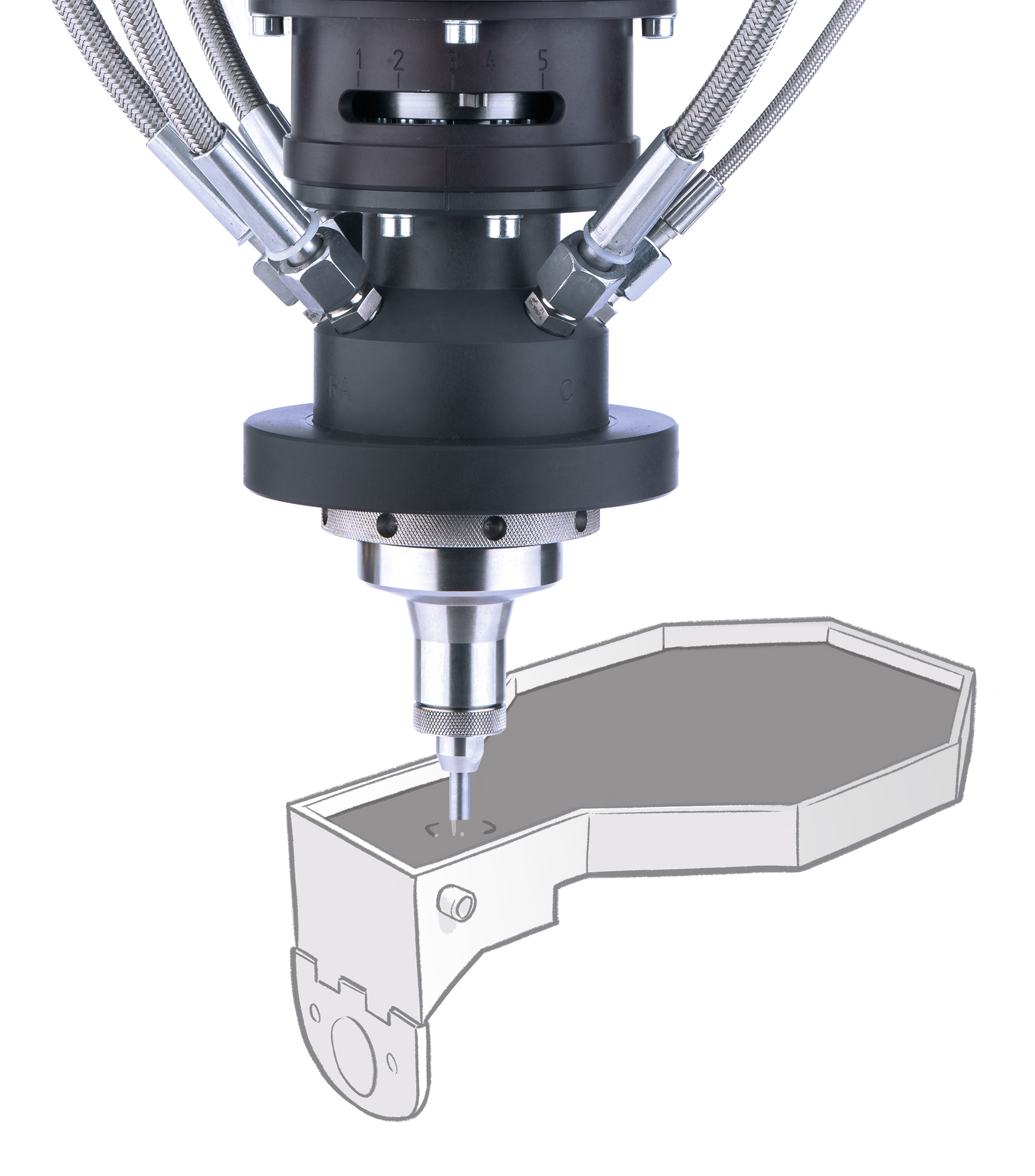

Bonding

We process all kinds of multi-component adhesives into precise reactive products for joining components. The components can be pre-treated to improve adhesion. The high-precision joining process can be manual or fully automated. Integrated curing-on-demand systems accelerate the curing process. When joining components in a vacuum, products such as displays are affixed without air bubbles (optical bonding).

ADDED VALUE

- Optimum reactivity thanks to dynamic or static mixing technology, including for viscous adhesives

- Permanently stable joints thanks to integrated surface activation

- Short cycle times thanks to intelligent joining tools

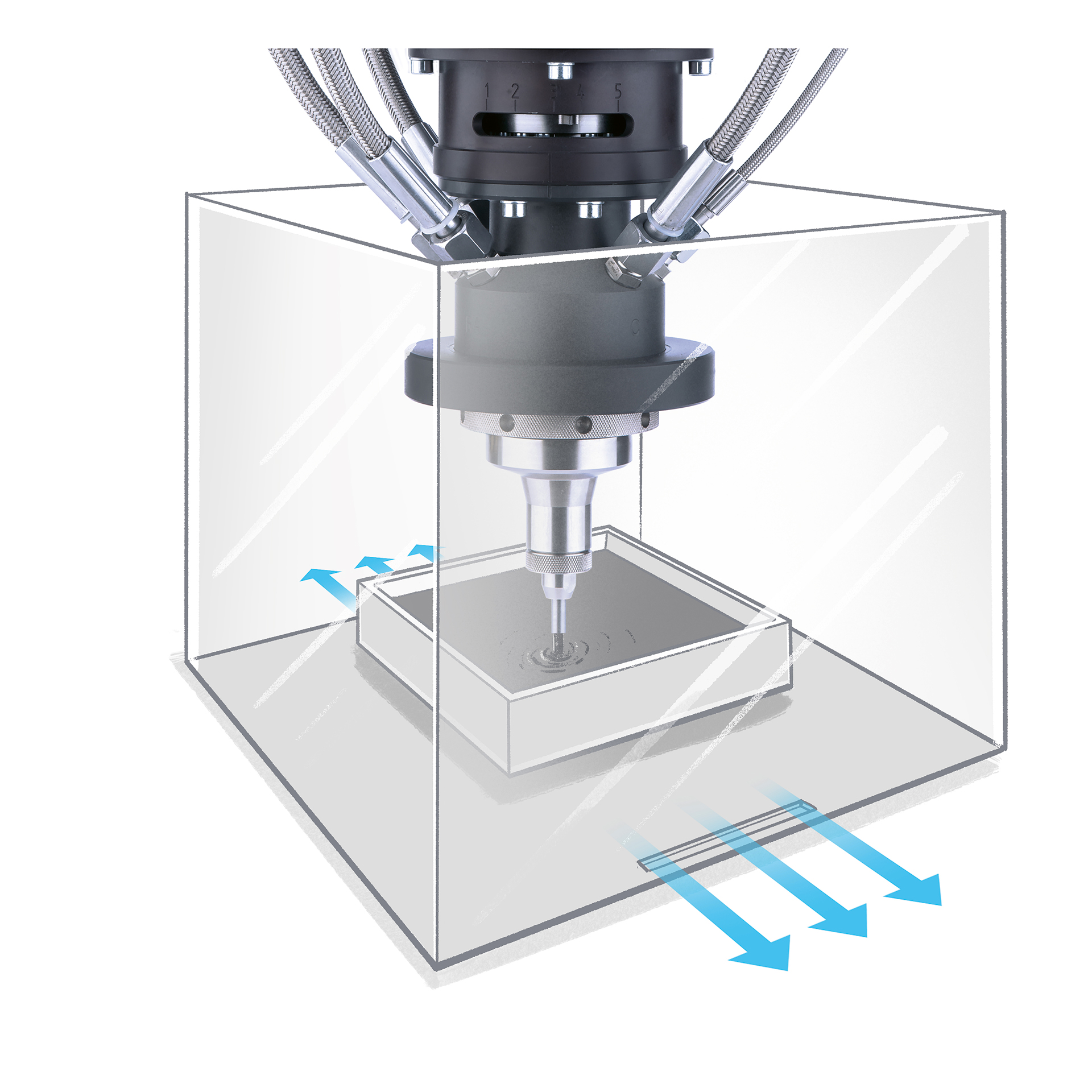

Conducting

Reactive polymer-based pastes that are thermally and electrically conductive protect sensitive electronic components by dissipating heat and electrostatic charge. Thanks to the powerful mixing and cleaning technology of our wear-resistant dispensing systems, the highly filled, multi-component gap fillers are optimally processed and then dispensed with pinpoint accuracy using our robot systems. With the help of integrated process monitoring and quality control, we ensure the best production results.

ADDED VALUE

- Permanent conductivity and protection of electronic components through the precise dispensing of highly abrasive conductive pastes

- Static mixing, including for the smallest dispensing quantities

- Low-wear piston dispensing systems ensure maximum precision, even at high dispensing speeds

Global Support. Anytime. Anywhere.