Composite Mold Making

For Maximum Precision and Efficiency

In composite mold making, every detail determines quality, strength, and efficiency. RAKU® TOOL boards, custom castings, pastes, and resin systems enable precise, economical, and repeatable production of models, molds, and high‑performance composite parts. From monolithic components to large‑scale CFRP structures, our materials deliver maximum stiffness, dimensional stability, and efficiency—perfectly matched to modern manufacturing processes in the composite industry.

- High dimensional and form stability

- Excellent machinability for precise contours

- Superior surface quality; resistant to temperature and chemical exposure

- Long service life and durability in toolmaking

- Precise production of models and molds for composite processes

- Serve as negative molds or tools for part production

- Enable manufacturing of complex geometries

- Ensure high-quality surfaces of finished composite parts

- Support efficient and repeatable manufacturing processes

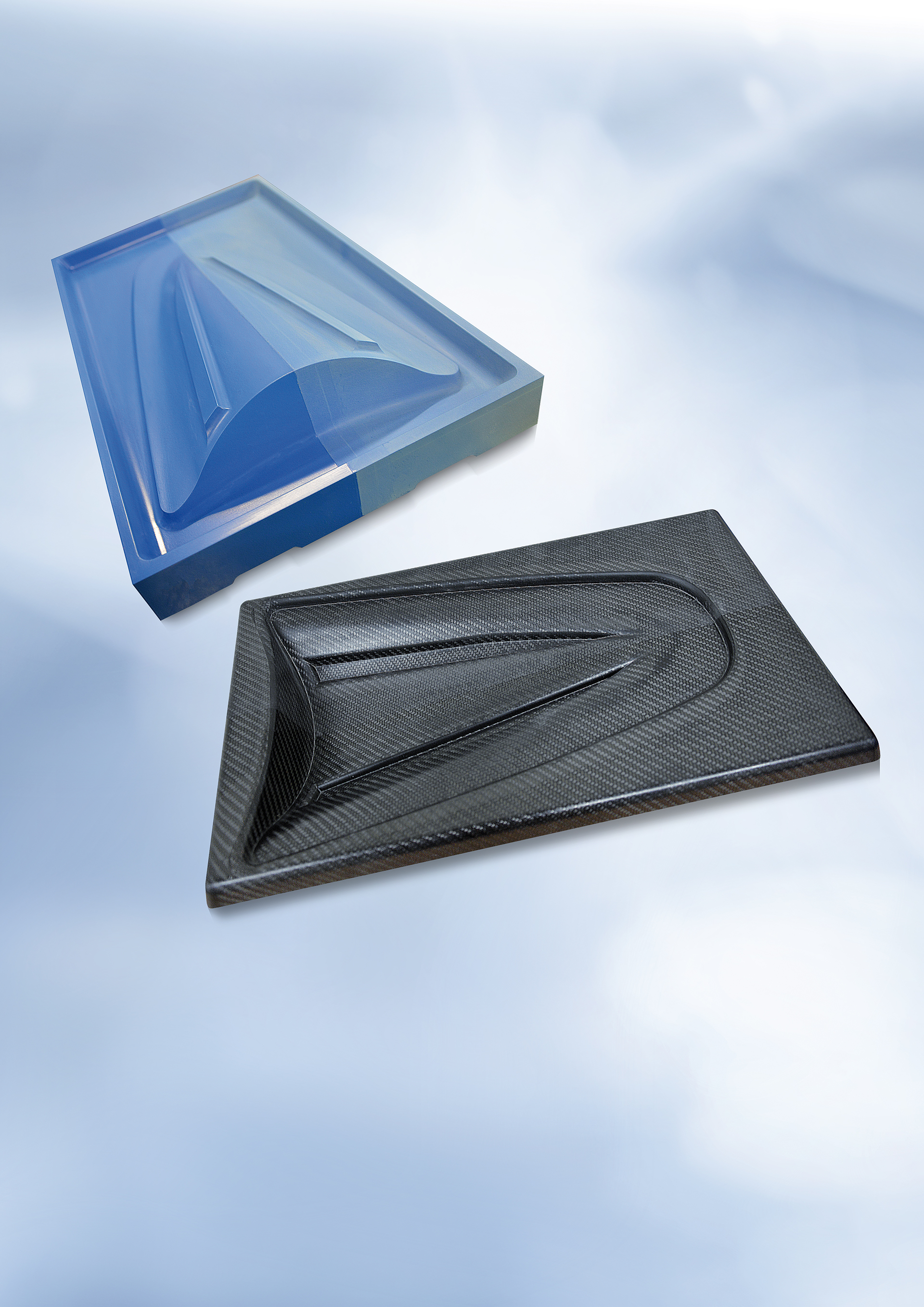

Our epoxy boards deliver maximum precision for models and molds in the composite sector. Their compact surface reduces sealer consumption and rework. The materials offer low warpage, easy machining, and compatibility with all standard release systems. Combined with high‑performance adhesive and repair products, they ensure short process times and reliable results—ideal for a wide range of lightweight composite applications.

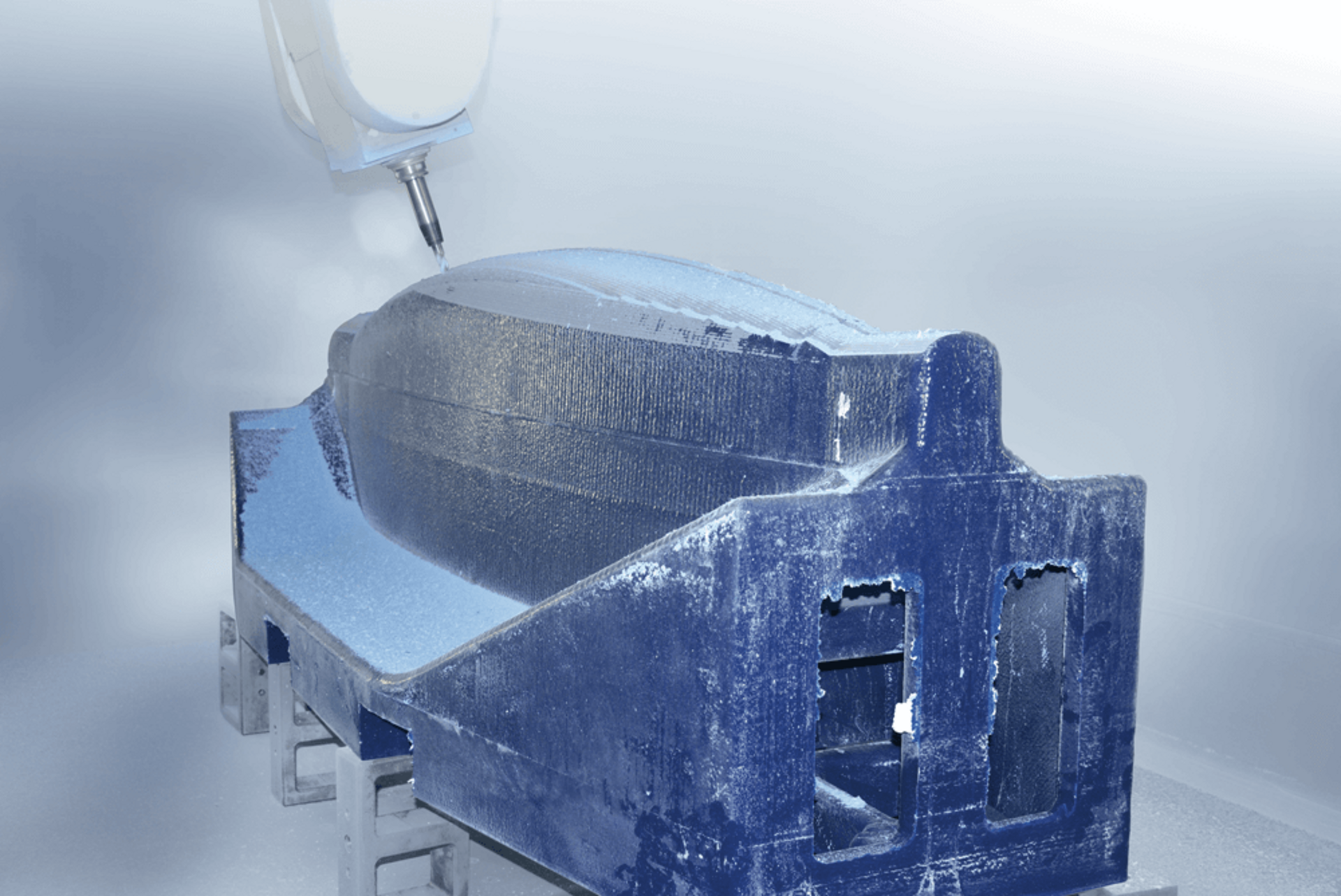

Close Contour Pastes create seamless, large‑format surfaces for economical model and mold production. With cost‑effective substructures and short milling times, they support efficient model building with minimal waste and excellent dimensional stability. Thanks to manual or CNC application, low exotherm, and outstanding adhesion—even on vertical surfaces—they are perfect for large‑scale composite mold making projects. Precision results at maximum efficiency.

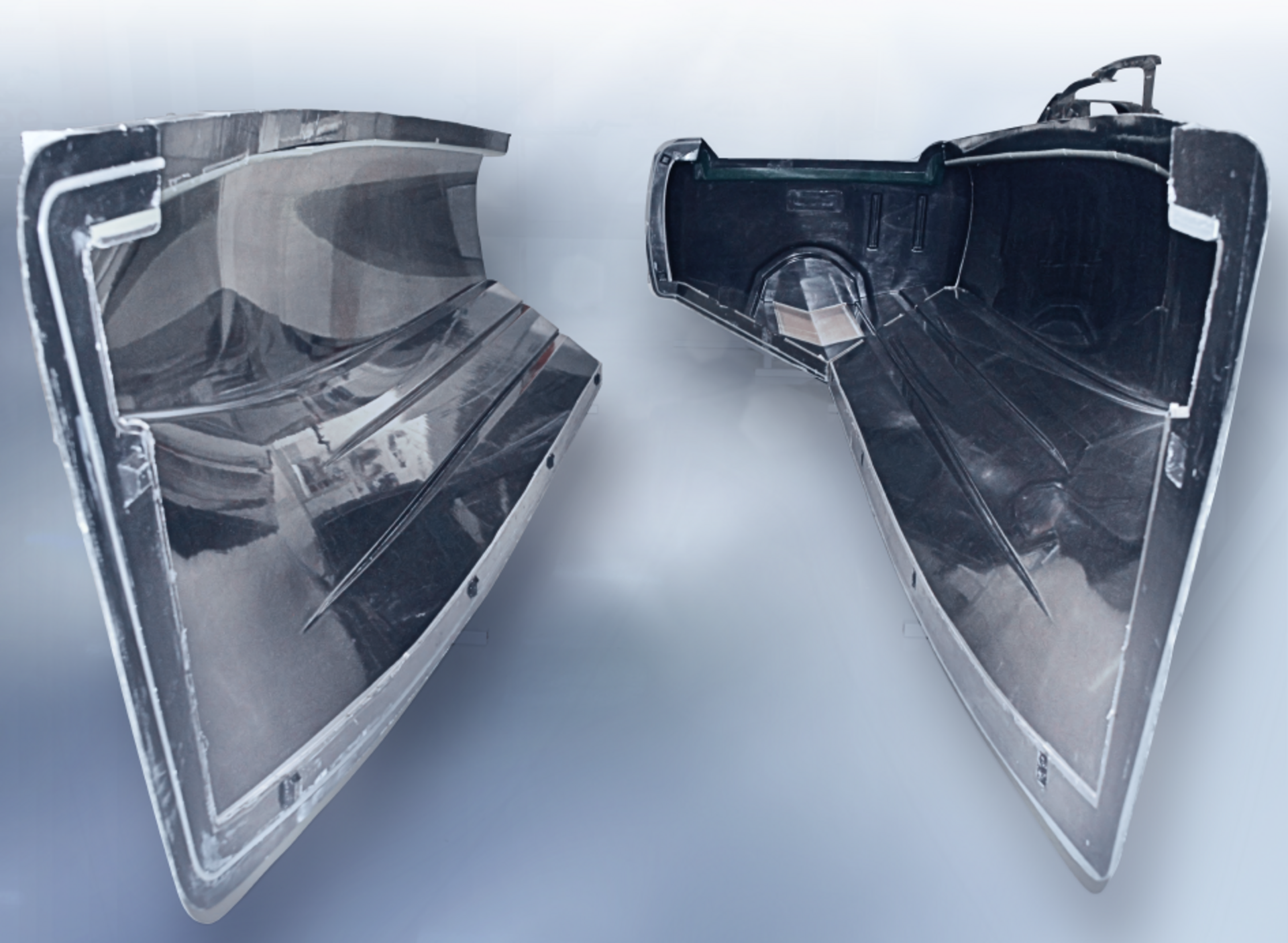

Our infusion and laminating systems deliver high‑strength, lightweight composite components for maximum performance. From polishable gelcoats to mechanically robust laminating resins and low‑viscosity infusion systems, all solutions offer optimal wetting properties, high temperature resistance, and reliable processing without outgassing. For precise, durable composite parts in demanding applications.

Close Contour Casting and Boards provide ready to mill, custom castings for fast and accurate results in mold making. The monolithic, seamless castings deliver superior surface quality, exceptional dimensional stability, and significantly reduced milling waste. With less pre‑processing, shorter production times, and lower manufacturing costs, they are ideal for complex geometries and demanding composite applications.

More information about the product range:

Download PDFGlobal Support. Anytime. Anywhere.