Precision Without Compromise!

Checking Jigs and Fixtures That Deliver Consistent Excellence! With RAKU® TOOL CC-6010

How can high-precision fixtures be manufactured efficiently and cost-effectively?

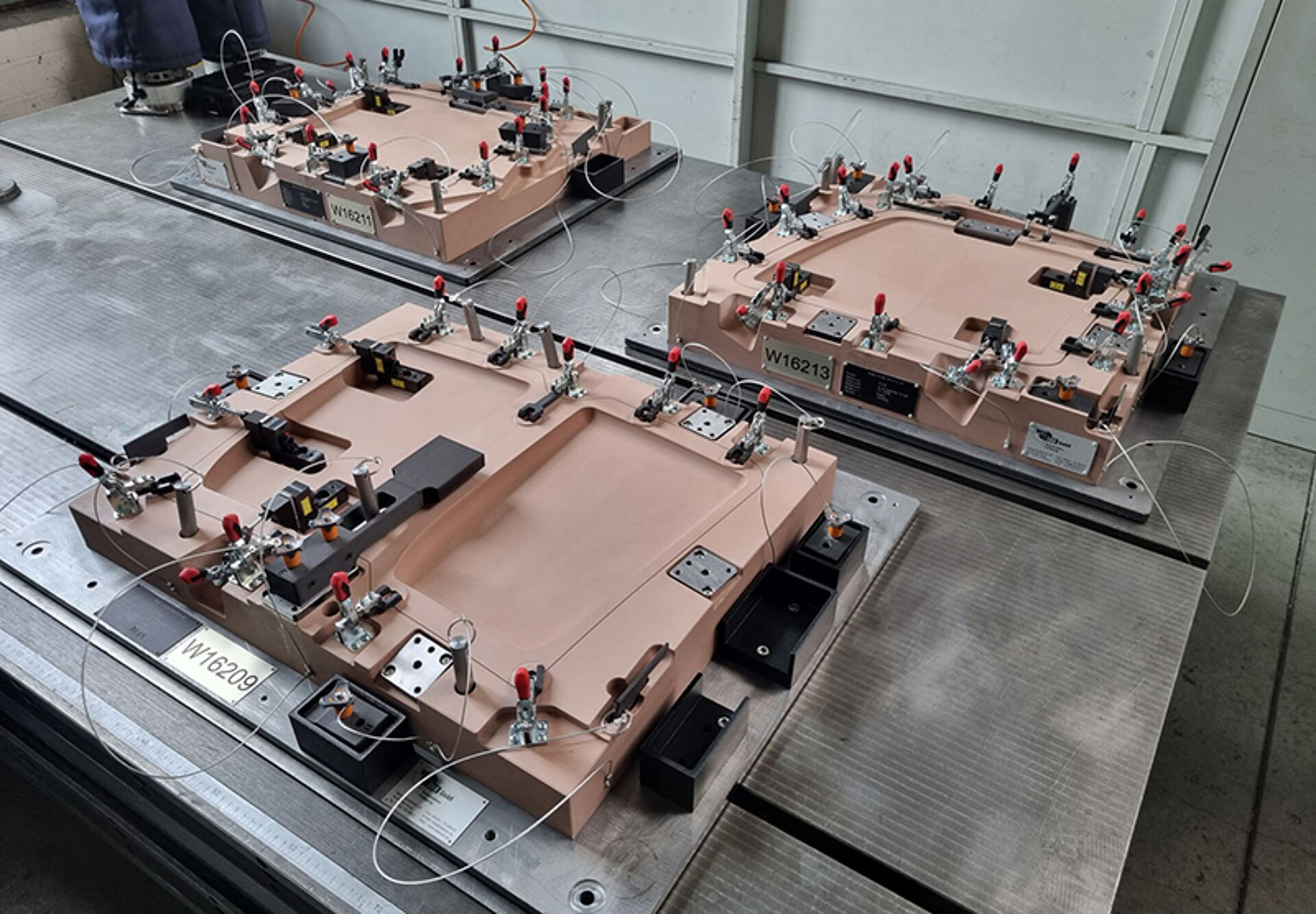

Our latest case study demonstrates how medium-sized checking jigs and component fixtures are produced using RAKU® TOOL CC-6010 – a polyurethane material renowned for exceptional machinability, dimensional accuracy, and strength.

Thanks to the intelligent combination of precision milling and modern 3D printing, robust, high-performance components for series production are created – perfectly tailored to the demands of modern manufacturing processes.

Application

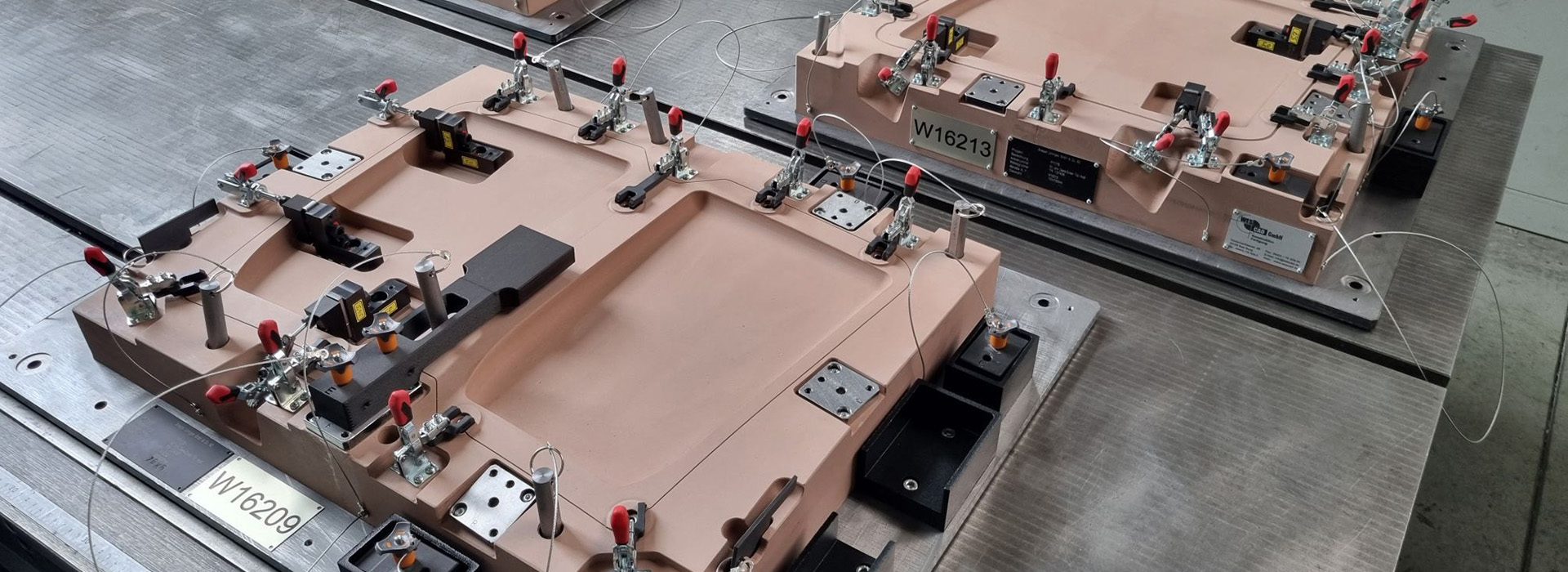

Medium-Sized Checking Jigs and Component Fixtures Made from RAKU® TOOL CC-6010

In modern series production, precise application is essential for quality and process reliability. By strategically combining high-performance materials – such as RAMPF’s polyurethane Close Contour Casting – with intelligent machining technologies, ultra-precise checking jigs and component fixtures are produced with outstanding accuracy and consistency.

Requirements for the plastic material RAKU® TOOL CC-6010:

- Good machinability

- High Strength / Dimensional Accuracy

Manufacturing Process

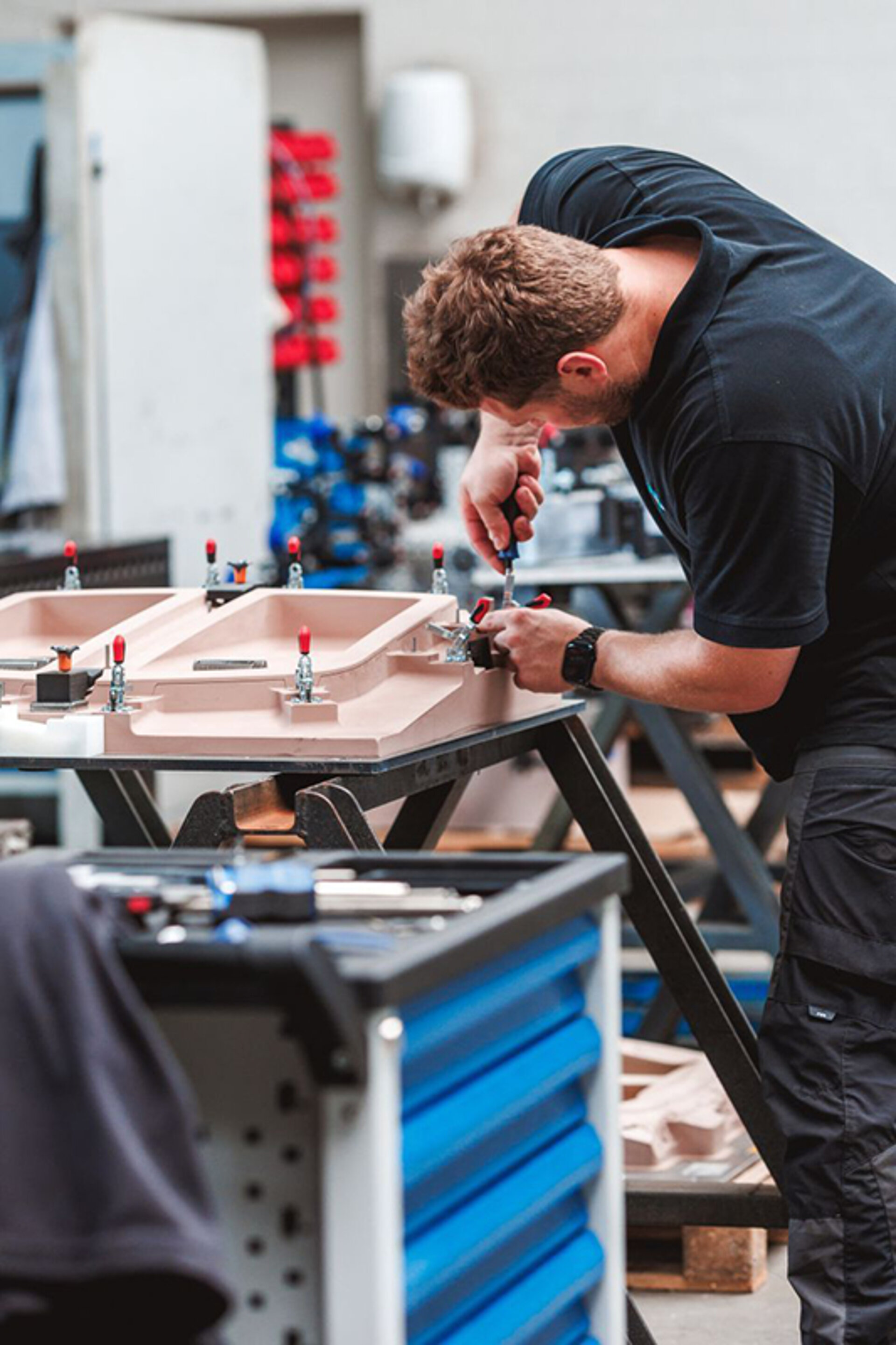

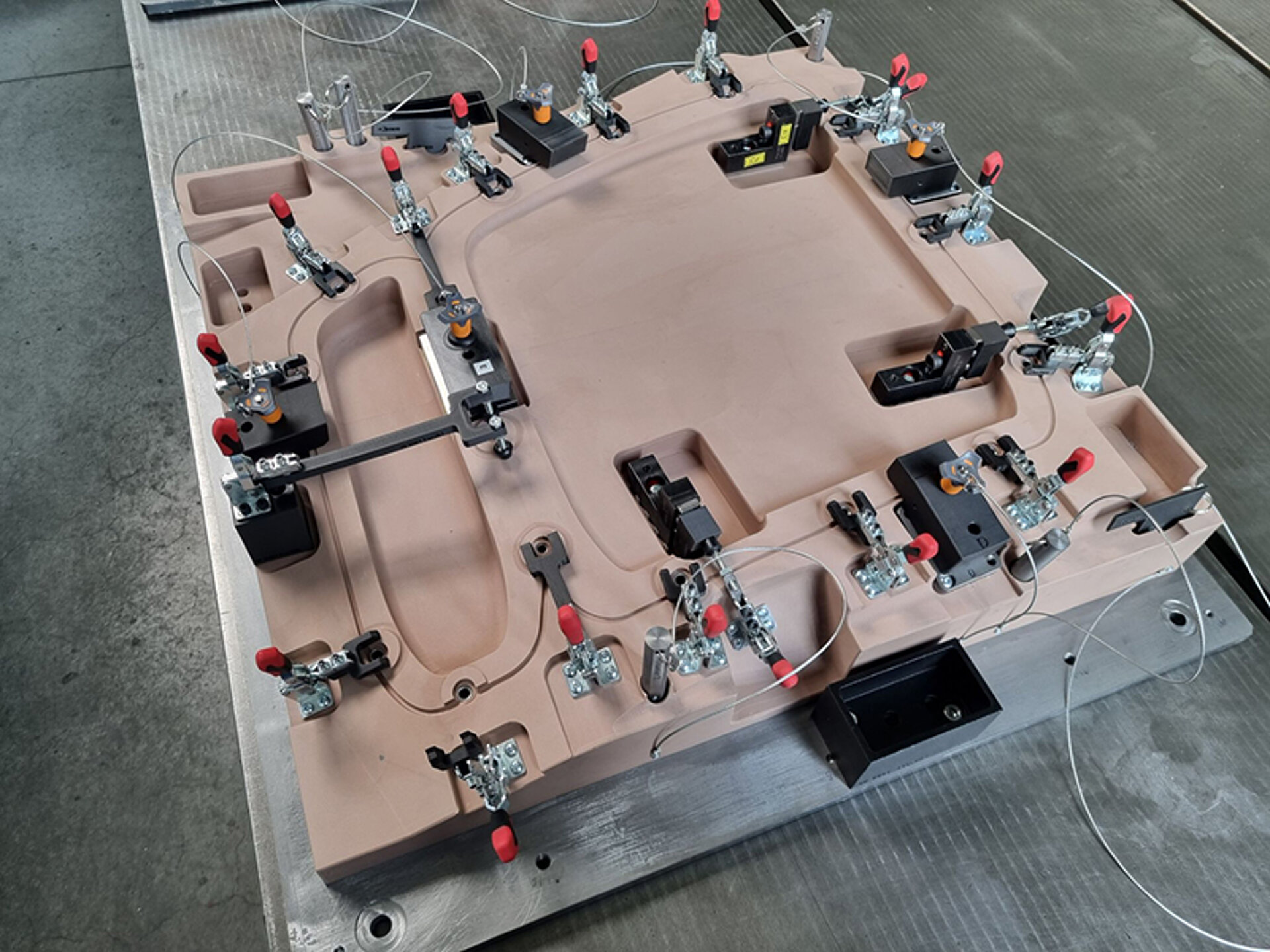

The manufacturing process combines precision milling with advanced 3D printing technologies to produce stable, high-performance fixtures.

1. The base structure is milled from RAKU® TOOL to ensure a perfectly tailored contour for precise positioning.

2 .Clamping arms and inspection elements are produced using 3D printing with carbon fiber-reinforced Onyx.

3. The milled RAKU® TOOL fixture, combined with custom-fit 3D-printed components, delivers optimal precision for component inspection in your production process.

Product Information Close Contour Casting RAKU® TOOL CC-6010

Further applications

- Styling models

- Master models

- Data control models

Added Value

- High-Quality Checking Jigs and Component Fixtures.

- Exceptional dimensional accuracy and stability combined with excellent machinability. Even complex geometries can be manufactured with high precision.

- Close Contour Castings are three-dimensional castings already close to the final contour, resulting in reduced milling and minimal waste.

- Optimal surface quality – seamless, fine, and dense – for minimal finishing.

- The result: perfect fit, stable hold, and consistently high process reliability.

Precision and Exceptional Repeatability!

A stable component fixture made from

RAKU® TOOL CC-6010, combined with the precise positioning of inspection elements made from Onyx, delivers the accuracy needed to meet the highest quality standards.

Inspect your components with customized tooling designed specifically for your needs!

Global Support. Anytime. Anywhere.