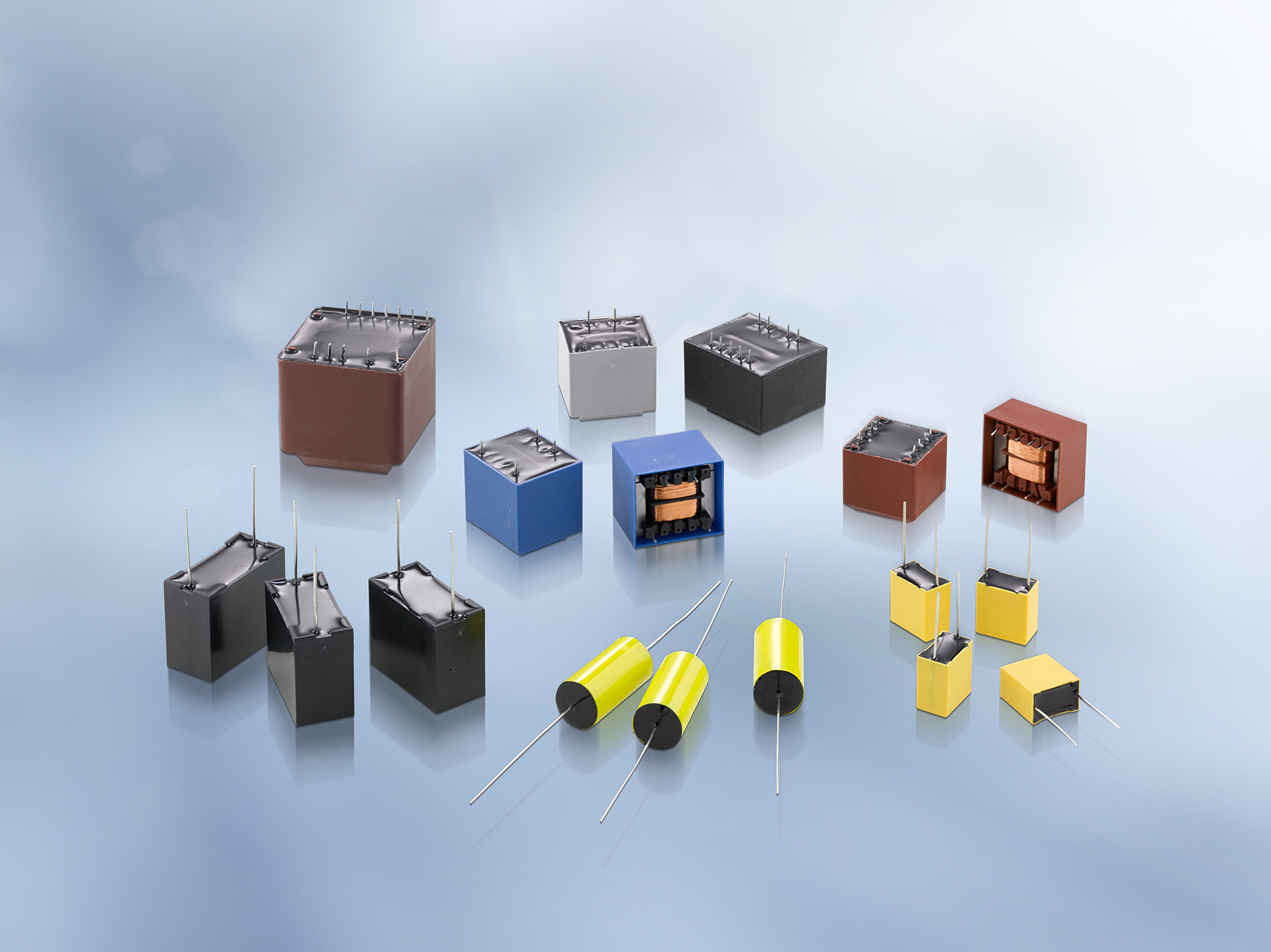

Potting Compounds for Electronics

Maximum Protection for Sensitive Components

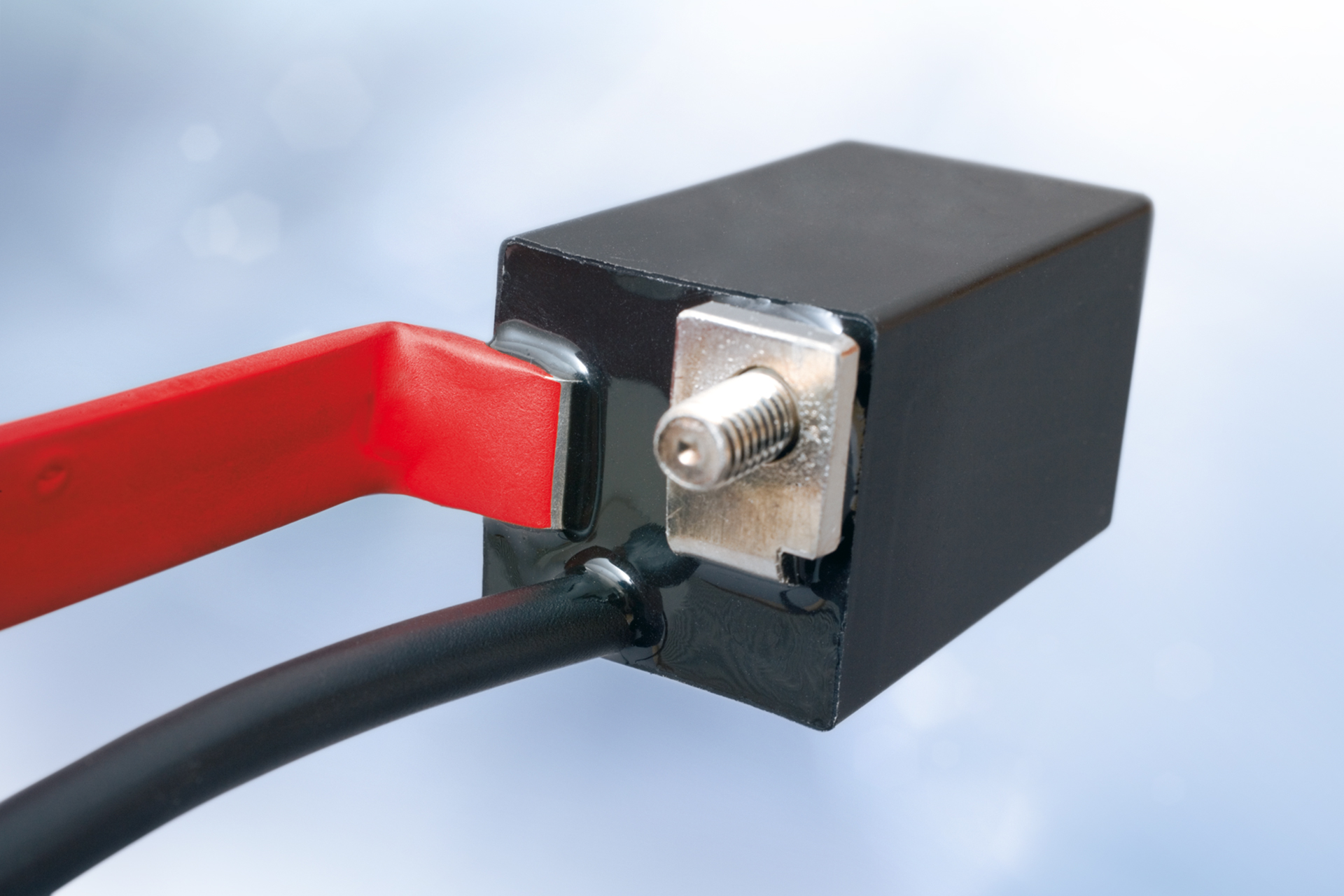

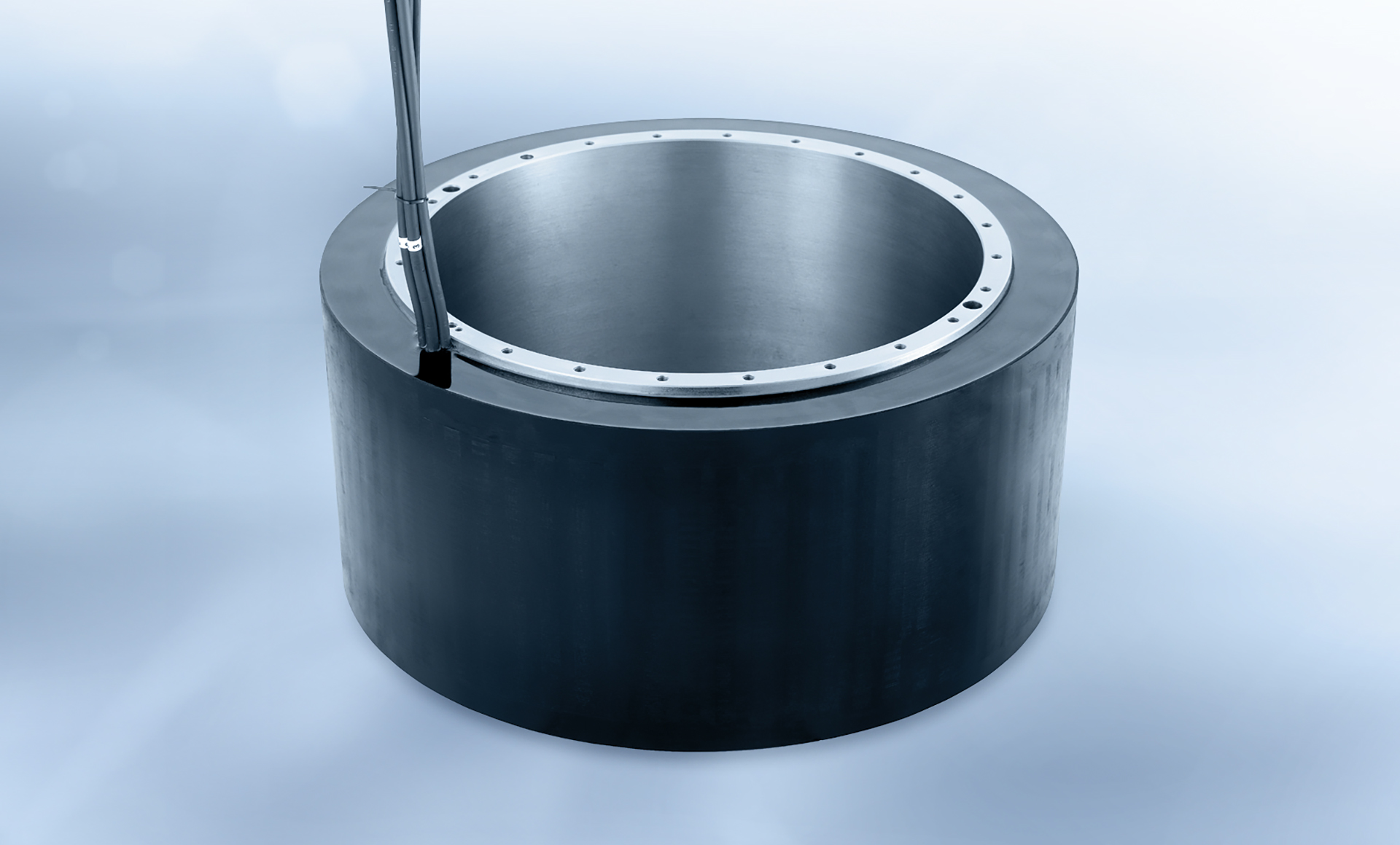

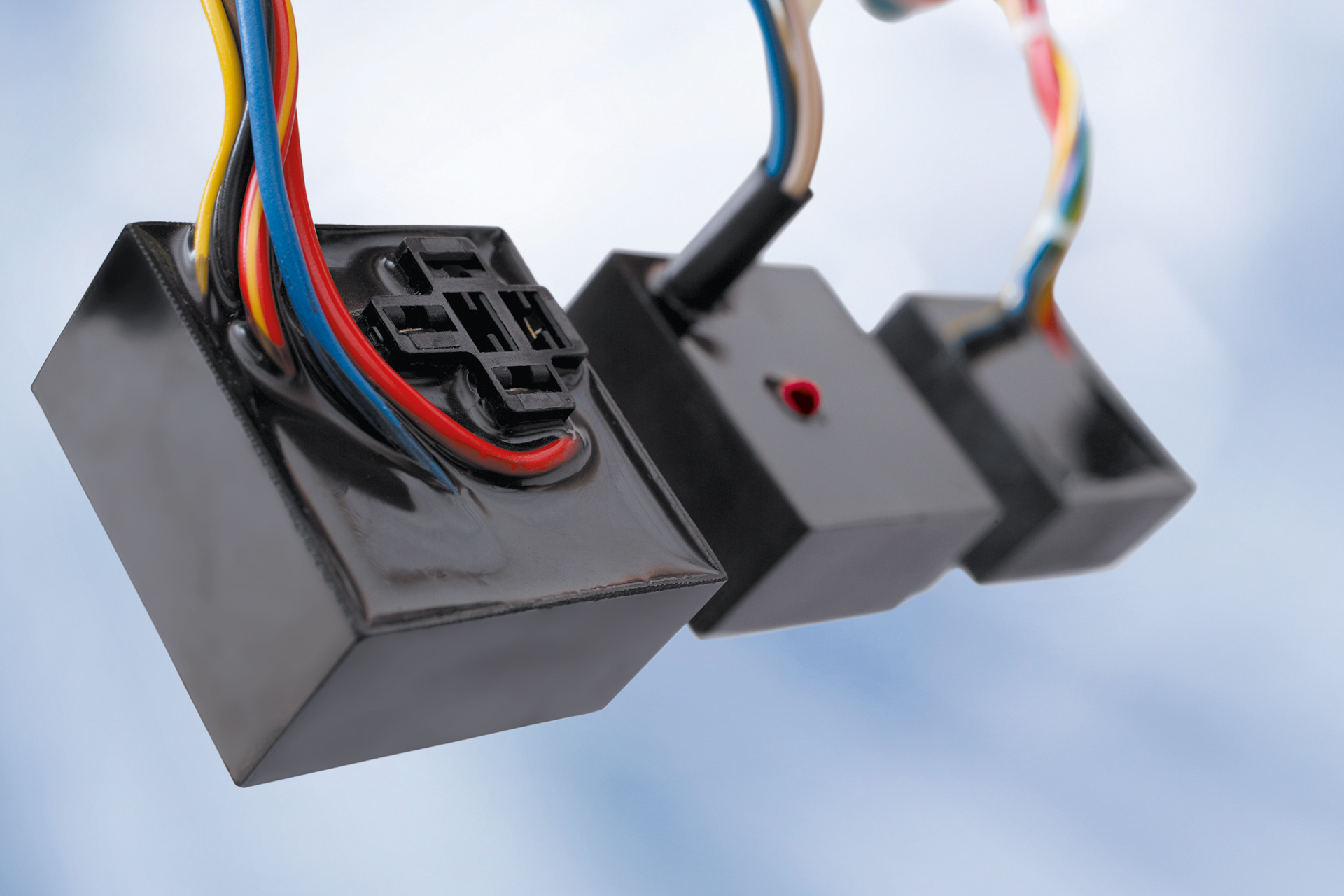

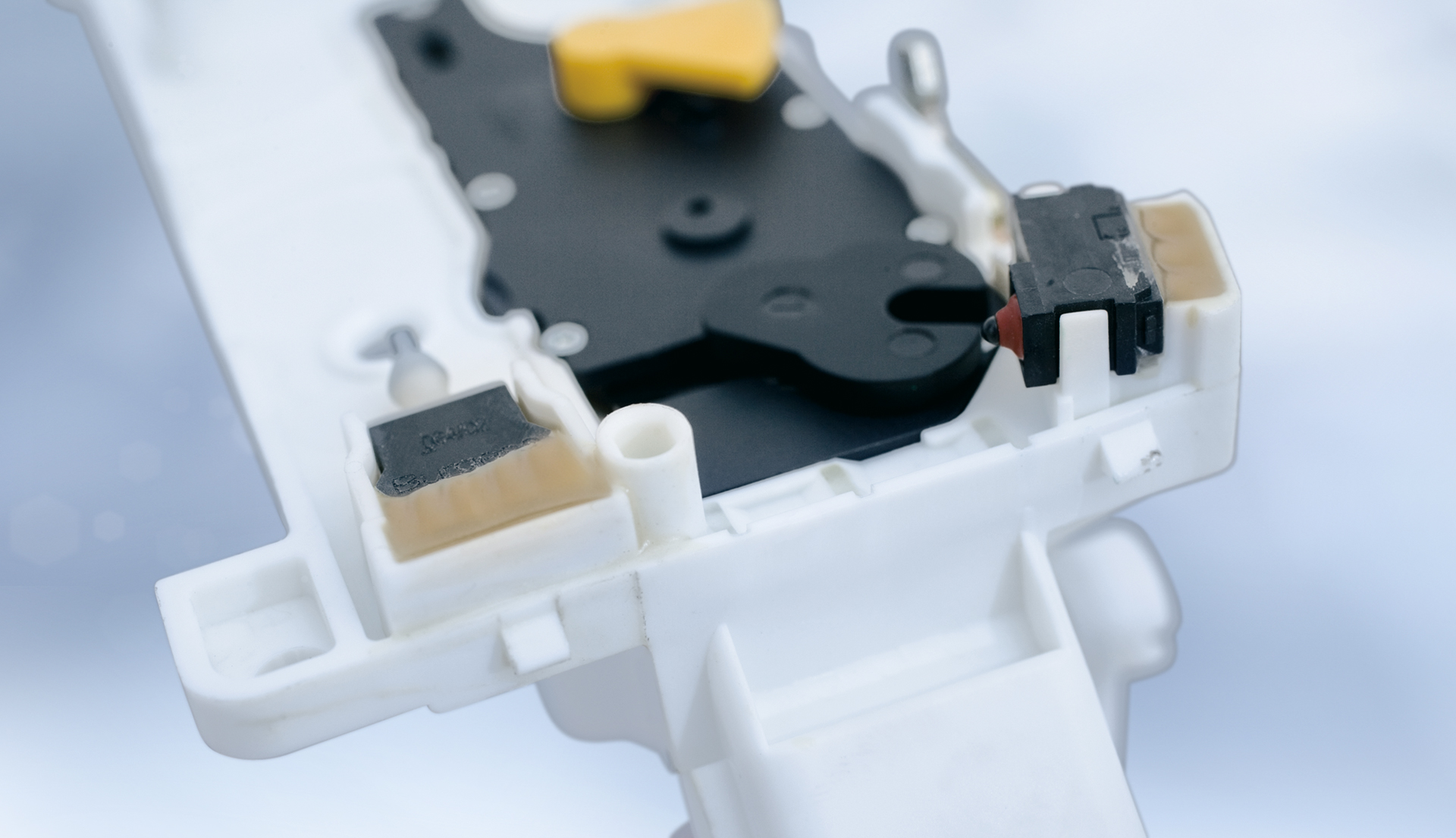

Our potting compounds provide robust protection for electronic and electrical components against moisture, chemicals, and extreme temperatures. Whether in automotive, energy, or industrial applications – our epoxy, polyurethane, and silicone-based solutions safeguard the performance and service life of your components. Benefit from high thermal and mechanical strength, controlled curing, and high resistance to heat and chemicals.

Properties and Functions

- High mechanical strength and thermal strength for long-term reliability

- Efficient heat dissipation reduces thermal stress and prevents overheating

- High chemical and temperature resistance for harsh environments

- Customizable processing time for flexible production processes

- RoHS-compliant and UL-certified to meet the highest safety standards

Your Key Benefits

Material Types

Chemical reaction

- Two-component

- Polyaddition reaction

- Minimal exothermic reaction

- Cures at room temperature

- Curing conditions can be flexibly adjusted by adding a catalyst

- Low shrinkage pressure on cast components

Area of application

- Temperature range: -60 to +155 °C, short-term: +160 °C

- Wide range of mechanical properties, from tough to highly elastic

Properties

- Excellent resistance to fluctuations in temperature for sensitive components

- High crack resistance for flexible products

- Good chemical resistance

- Low water absorption

- Impressive electrical properties

- Tg: from -75 to +120 °C

- RTI: to 155 °C

- OBJS2-listed

Adhesion

- Good adhesion to housings and components

- Good adhesion to plastics such as PA, PBT, and ABS

Flame retardancy

- Can be adapted to UL 94 V0

Learn more!

Chemical reaction

- One or two components (1C or 2C)

- Homopolymerization (1C) and polyaddition reaction (2C)

- Cures at room temperature

- Curing can be accelerated using heat

- Heat curing required for one-component and hot-curing epoxy

- Good impregnation properties

- Low sensitivity to moisture

Area of application

- Temperature range: -40 to +180 °C, short-term: +200 °C

Properties

- High thermal dimensional stability

- Low coefficient of thermal expansion

- High dielectric strength

- High media resistance to fuels

- Low water absorption and water vapor permeability

- Tg: -20 to +180 °C

- OBJS2-listed

Adhesion

- Good adhesion to metals

Flame retardancy

- Can be adapted to UL 94 V0

Learn more!

Chemical reaction

- One or two components

- Polyaddition and polycondensation reaction

- Minimal exothermic reaction

- Cures at room temperature

- Curing can be accelerated using heat

- Curing without by-products possible (polyaddition reaction)

- Low shrinkage pressure on cast components

- Low sensitivity to moisture

- Hydrophobic

Area of application

- Wide temperature range: -60 to +200 °C, short-term: +250 °C

- Optimum physical properties, virtually constant over the entire application temperature range

Properties

- Very good resistance to temperature fluctuations

- High crack resistance

- Excellent chemical resistance for extreme environments

- Low water absorption

- High water vapor permeability

- Impressive UV and weather resistance

- Tg: always < 0 °C

Adhesion

- Good adhesion to mineral substrates

- Adhesion to other substrates often only with pre-treatment

Flame retardancy

- Can be adapted to UL 94 V0

Learn more!

Find here more information on processing diisocyanates according to REACH, Annex XVII, Entry 74:

Global Support. Anytime. Anywhere.