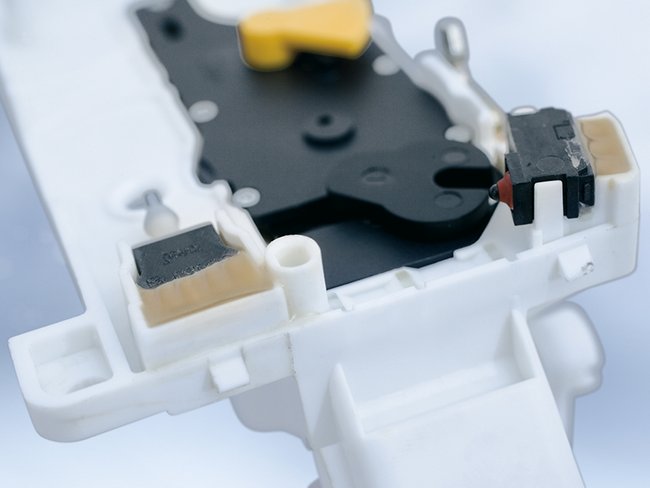

用于电气和电子部件

电子浇铸树脂是众多行业进一步发展的关键所在。汽车、能源、自动化和家用电器行业都严重依赖于电力存储和传输方面的发展。

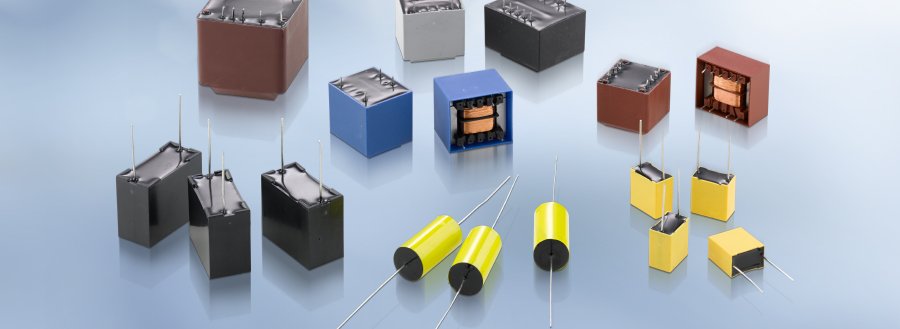

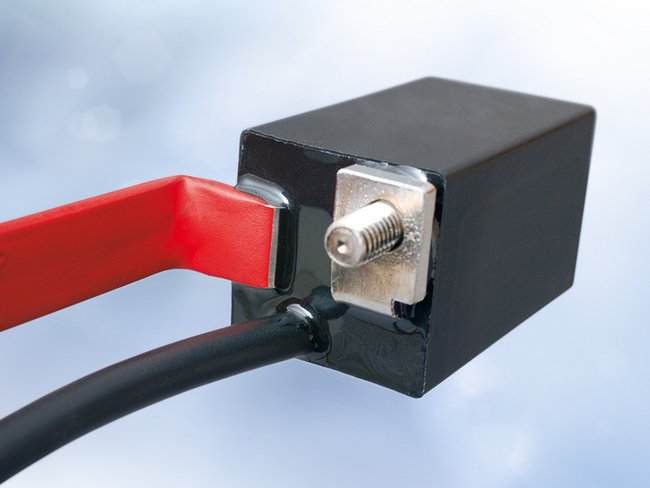

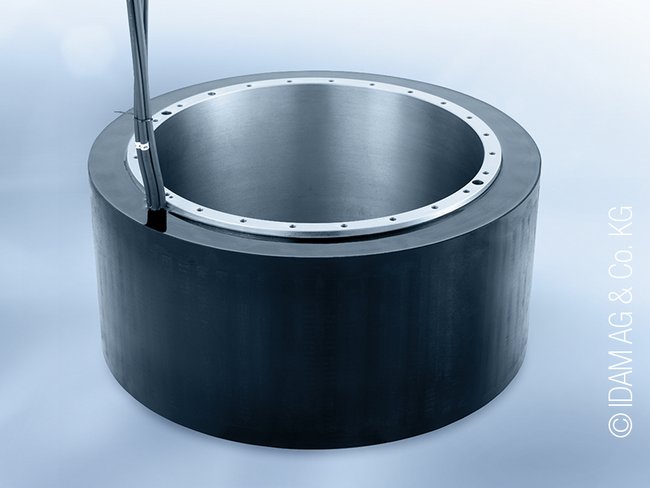

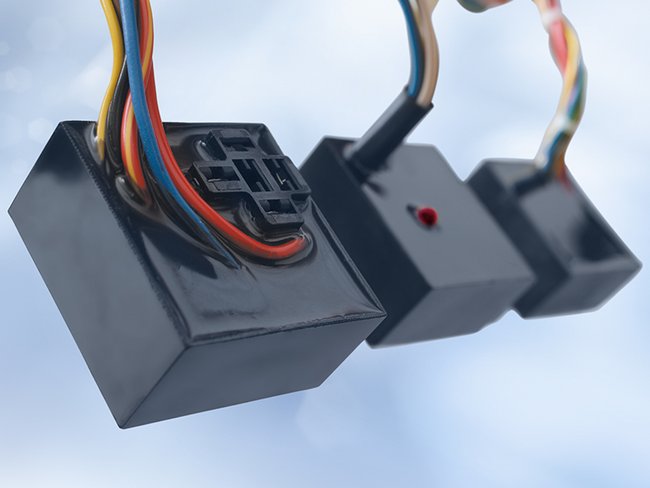

RAMPF Advanced Polymers 的单组分和双组分电子浇铸树脂提高部件的可靠性和性能,同时确保高成本效率和长使用寿命。您的部件(变压器、控制器、变频器、电动机等)将得到可靠而有效的保护,免受化学物质和热、冷、湿等环境因素的侵害。

使用我们基于聚氨酯(RAKU® PUR)、环氧树脂(RAKU® POX)和硅胶(RAKU® SIL)的产品的客户包括汽车和电子工业的领先制造商。

这些产品还拥有广泛的机械、热和化学属性。它们能通过有效地将您的部件上的热量传导出去来确保低的热应力。

即便在温度波动极大的情况下,材料仍能保持足够的弹性以减少部件中出现的应力。

作为混合及定量给料技术和自动化解决方案领域全球领先的专家之一,RAMPF Production Systems 运用其所拥有的广泛的专业知识,让一流的材料更加锦上添花。

材料、机器和过程——得益于蓝浦高度专业的全面服务。

Chemical reaction

- Two-component

- Polyaddition reaction

- Minimal exothermic reaction

- Cures at room temperature

- Curing conditions can be flexibly adjusted by adding a catalyst

- Low shrinkage pressure on cast components

Area of application

- Temperature range: -60 to +155 °C, short-term: +160 °C

- Wide range of mechanical properties, from tough to highly elastic

Properties

- Excellent resistance to fluctuations in temperature for sensitive components

- High crack resistance for flexible products

- Good chemical resistance

- Low water absorption

- Impressive electrical properties

- Tg: from -75 to +120 °C

- RTI: to 155 °C

- OBJS2-listed

Adhesion

- Good adhesion to housings and components

- Good adhesion to plastics such as PA, PBT, and ABS

Flame retardancy

- Can be adapted to UL 94 V0

Chemical reaction

- One or two components (1C or 2C)

- Homopolymerization (1C) and polyaddition reaction (2C)

- Cures at room temperature

- Curing can be accelerated using heat

- Heat curing required for one-component and hot-curing epoxy

- Good impregnation properties

- Low sensitivity to moisture

Area of application

- Temperature range: -40 to +180 °C, short-term: +200 °C

Chemical reaction

- One or two components

- Polyaddition and polycondensation reaction

- Minimal exothermic reaction

- Cures at room temperature

- Curing can be accelerated using heat

- Curing without by-products possible (polyaddition reaction)

- Low shrinkage pressure on cast components

- Low sensitivity to moisture

- Hydrophobic

Area of application

- Wide temperature range: -60 to +200 °C, short-term: +250 °C

- Optimum physical properties, virtually constant over the entire application temperature range

Properties

- Very good resistance to temperature fluctuations

- High crack resistance

- Excellent chemical resistance for extreme environments

- Low water absorption

- High water vapor permeability

- Impressive UV and weather resistance

- Tg: always < 0 °C

Adhesion

- Good adhesion to mineral substrates

- Adhesion to other substrates often only with pre-treatment

Flame retardancy

- Can be adapted to UL 94 V0