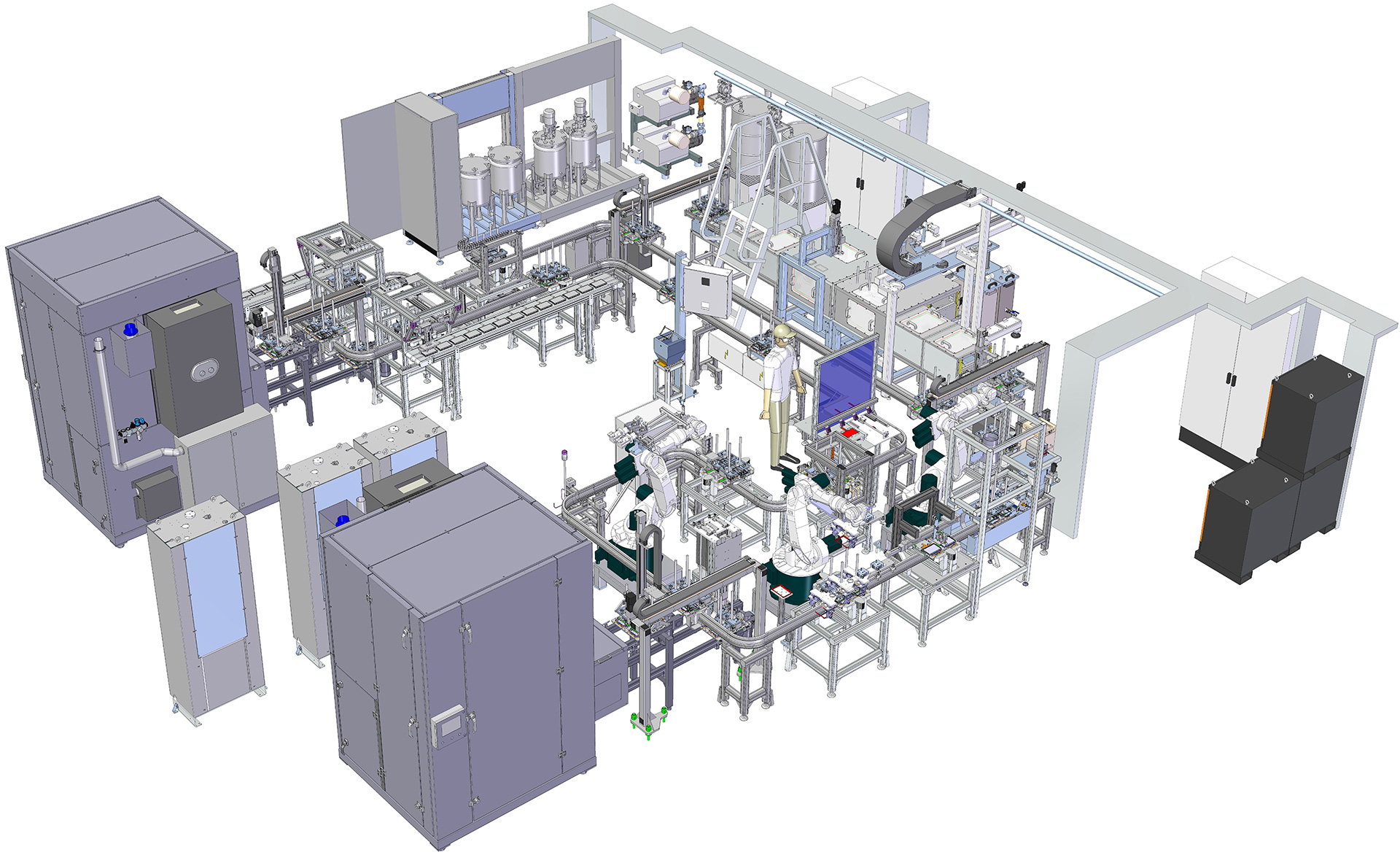

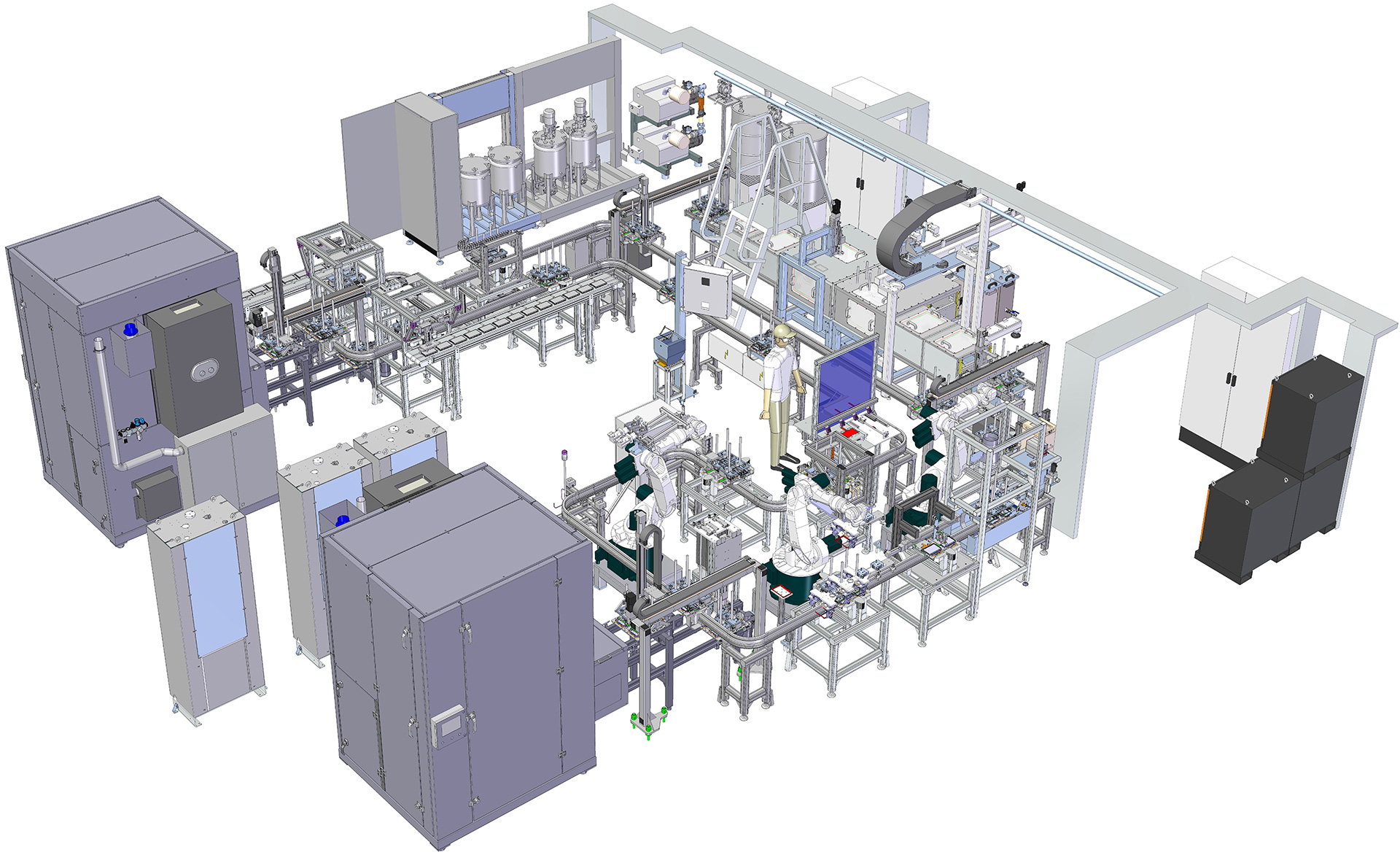

Automation of production facilities with integrated dispensing technology

Process Automation

In addition to our core competence of mixing and dispensing technology, we also provide product-specific automation concepts. These include handling and robotics, component transport, control technology, and the recording of all process parameters with MES connection.

Process automation at RAMPF also comprises constructing tools and equipment, pre-treatment of materials (activation), heat treatment, image processing and sensors, and contactless measuring technology.

Component transport (part carriers, conveyor belts, and rotary indexing tables)

Material preparation under vacuum

Dispensing under vacuum

Constructing tools and equipment

Control technology (e.g. SIEMENS, Beckhoff)

Recording all process parameters with MES connection

Heat treatment (infra-red, convexion, HF procedure)

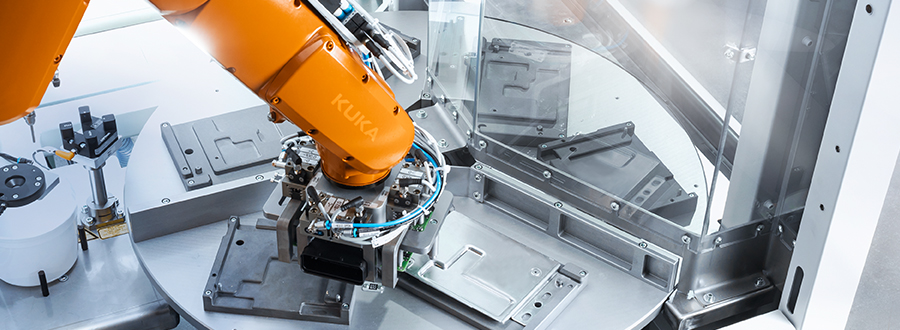

Handling and robotics (e.g. KUKA, ABB, FANUC)

Image processing and sensors / (non-contact) measurement technology

Contactless measuring technology