Wide range of possible uses

Foamed, soft or elastic, in solid or liquid form, but also hard: Silicone is used in numerous applications in all kinds of industries. Our silicone systems are used as both foam and compact sealing solutions and also as casting systems or adhesives.

Silicones are synthetic polymers made up of individual siloxane units, with silicon atoms and oxygen atoms combining to form molecular chains. Silicones are regarded as hybrids of inorganic chemicals (minerals, metals, salts, gases, etc.) and organic chemicals (hydrocarbons, alcohols, aldehydes, ketones, etc.).

Silicone elastomers, which are also available from RAMPF Advanced Polymers, currently account for 65% of all silicone production.

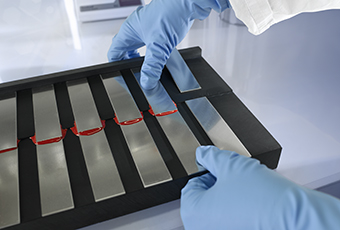

Our RAKU® SIL product portfolio includes hot and cold cross-linking systems, but also LSRs (liquid silicone rubbers) that are used with appropriate two-component mixing and dispensing systems for bonding, sealing, and casting.