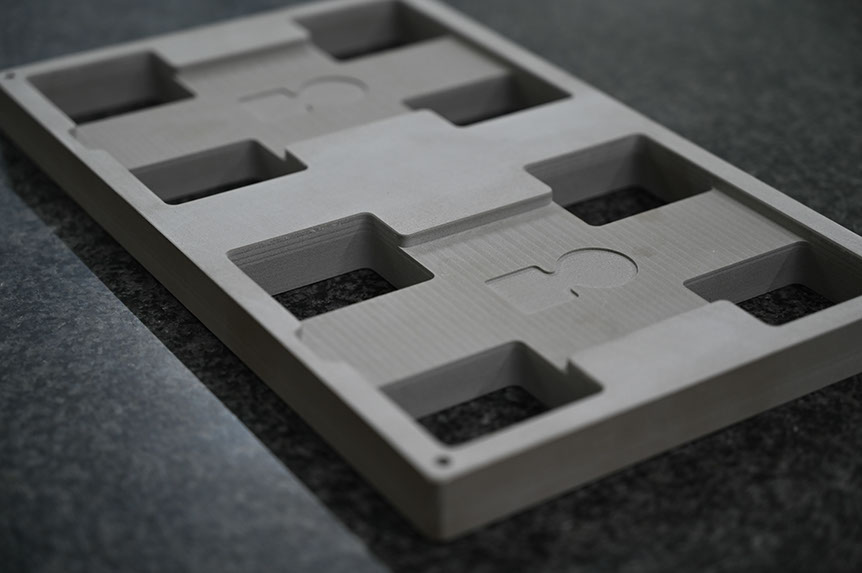

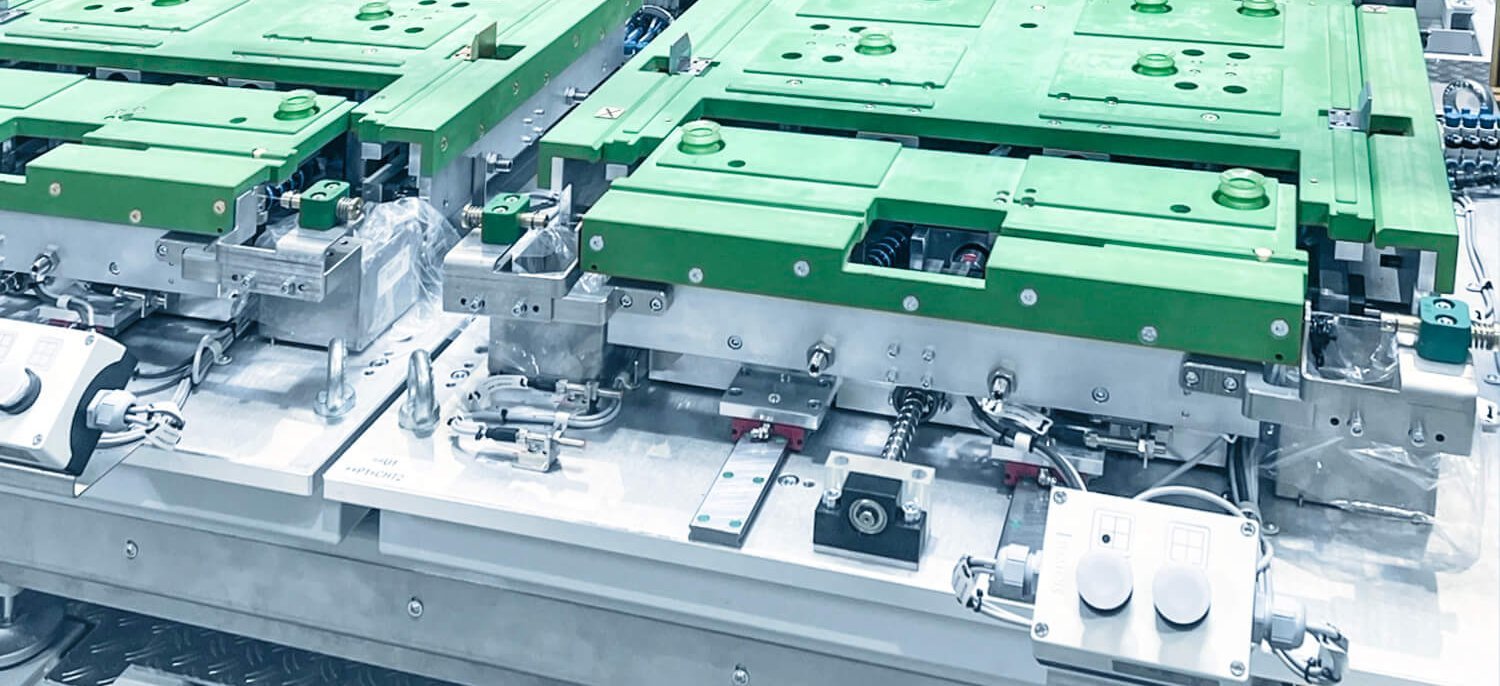

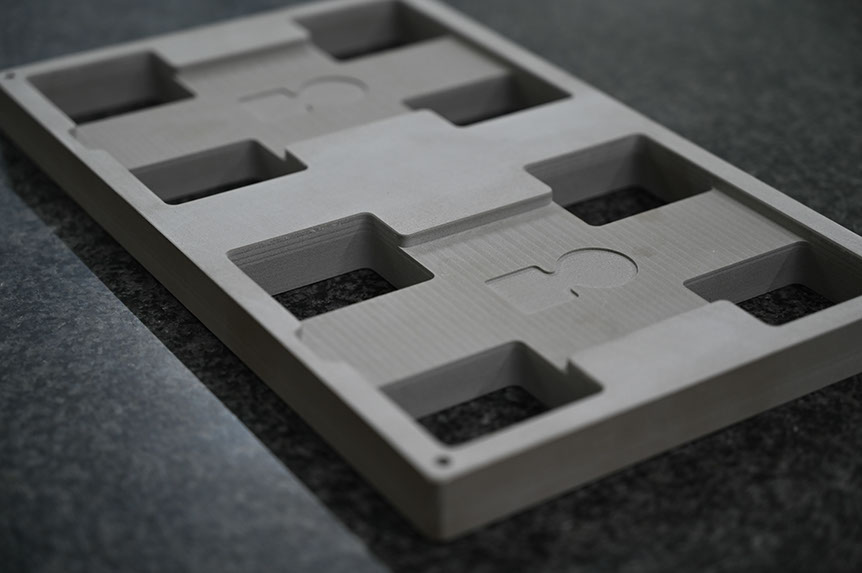

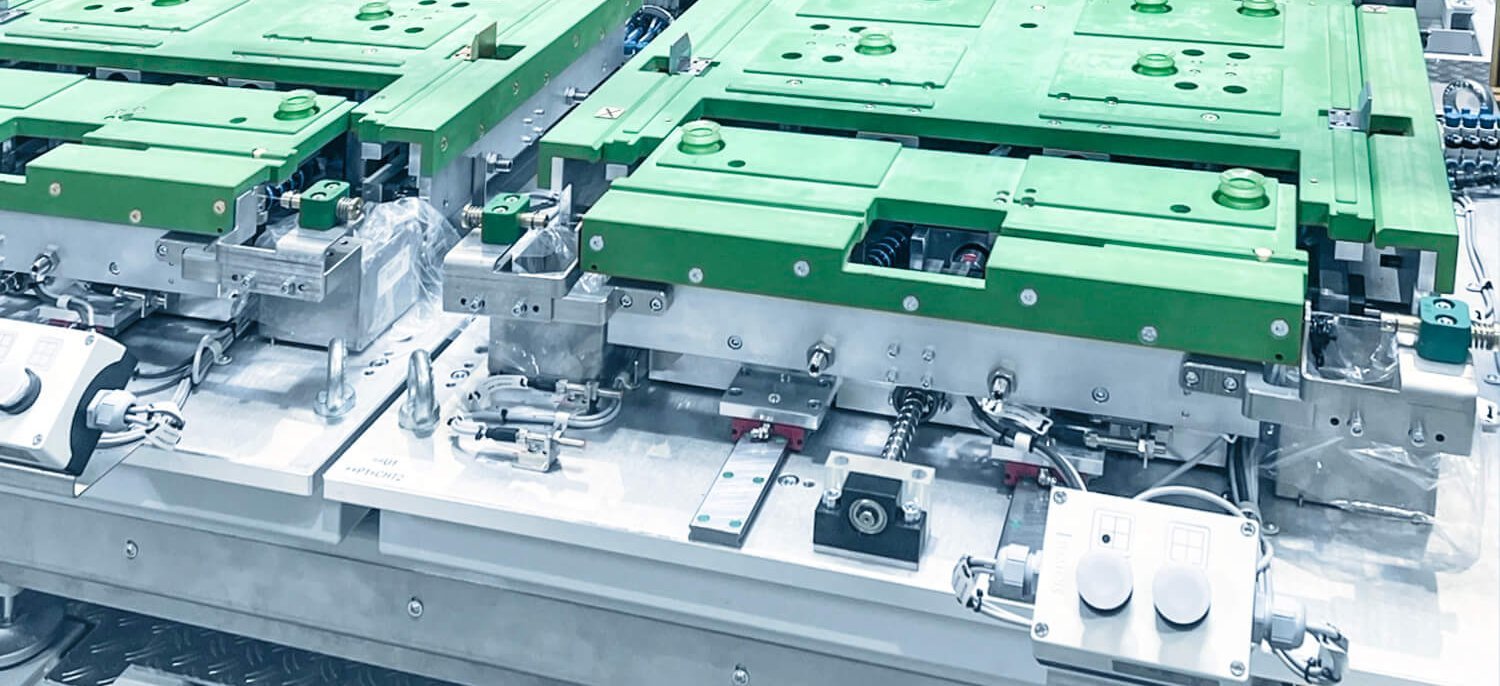

So much better than aluminum - RAKU® TOOL plastic workpiece carriers

Lighter. Faster. More sustainable. Precision without compromise for modern manufacturing processes.

So much better than aluminum - RAKU® TOOL plastic workpiece carriers

Lighter. Faster. More sustainable. Precision without compromise for modern manufacturing processes.