RAMPF Presents Gap Filler Know-How

Material and machine for effective thermal management: At Battery Show Europe – Stuttgart, May 7 to 9, Booth 830 – the international RAMPF Group is presenting its new two-component silicone elastomer RAKU® SIL 27-1004 as well as K-DP piston dispensing pumps for processing highly filled and abrasive materials.

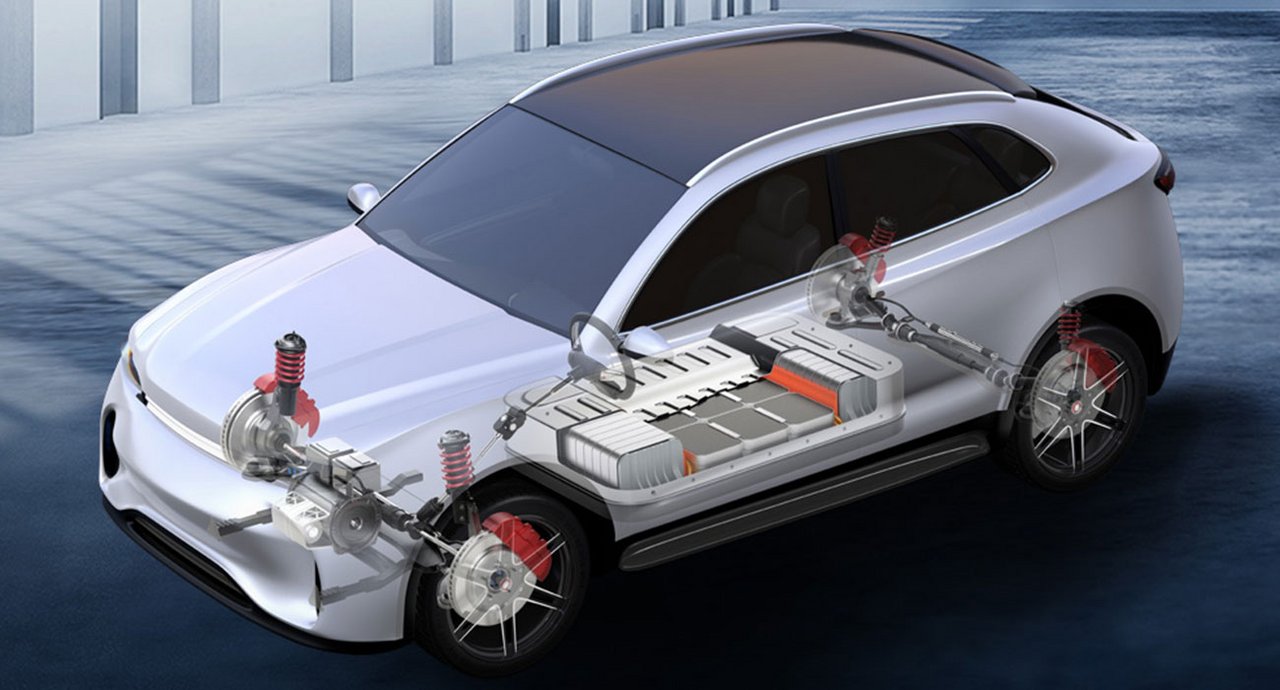

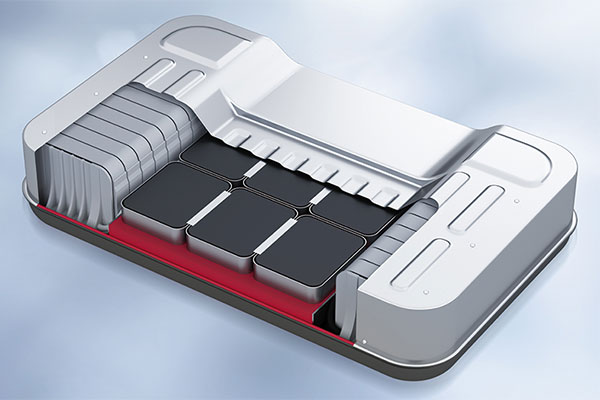

Gap fillers are mainly used in components of the power electronics and battery industries to close air gaps between the component and the heat sink. The high thermal conductivity of the gap filler is further increased by thinner glued joints and good wetting properties.

At Battery Show Europe 2019, the companies RAMPF Polymer Solutions and RAMPF Production Systems are presenting the following gap-filler highlights:

RAMPF Polymer Solutions Gap-Filler RAKU® SIL 27-1004

RAKU® SIL 27-1004 is a soft, thermally conductive, paste-like, two-component silicone elastomer that features

- very good thermal conductivity

- quick reaction at room temperature

- fast cure when exposed to heat

- low shore hardness

- good electrical values

The form-in-place resin system has a temperature range from -60 to +200 °C and is used, amongst others, in electronic assemblies in the automotive, electronic components, and computer industries.

RAMPF Production Systems K-DP Piston Dispensing Pumps

RAMPF Production Systems has developed the low-wear, low-maintenance piston pumps KDP for the precise and high-speed application of gap fillers. KDP pumps are very versatile and can process thermal pastes with a dispensing capacity of more than 10g/sec. The system works according to the principles of volumetric forced dispensing and, for the most part, processes independently of pressure and viscosity.

The servo-drive technology allows for a variable rate of material discharge, so that all mixing ratios for two-component materials can be adjusted. The optimum adaptation to the process conditions is rounded off by the servo-electric transmission principle.

Further Highlights at the RAMPF Booth:

- Silicone foam gaskets – RAKU® SIL 37-1210 is listed with leading manufacturers in the automotive industry and exhibits low hardness and low compressive strength for low assembly forces. The foam also features high temperature resistance (up to 220 °C) and excellent chemical resistance. RAKU® SIL 37-1210 is used, amongst others, for sealing battery covers, charging stations, and charging connectors.

- Electro casting resins based on polyurethane, silicone, and epoxy exhibit high thermal, chemical, and mechanical resistance. Battery sensors and charging stations, charging plugs for electric vehicles, relays, and transformers are reliably and efficiently protected against chemical substances and environmental influences such as heat, cold, and moisture.

- Automation of production facilities with integrated dispensing technology – In addition to the company’s competence of mixing & dispensing technology, RAMPF Production Systems also provides product-specific automation concepts, which include handling and robotics, component transport, control technology, and the recording of all process parameters with MES connection. Constructing tools and equipment, the pre-treatment of materials (activation), heat treatment, image processing, and sensors as well as contactless measuring technology are also part of the process automation portfolio.