A World of Pioneers – RAMPF at K 2019!

Sealing systems, adhesives, and heavy-duty elastomers are the focus of RAMPF Polymer Solutions at this year's K trade fair in Düsseldorf. Get your free ticket now!

One booth – Ten strong partners

RAMPF Polymer Solutions is presenting customized sealing systems, adhesives, and heavy-duty elastomers at this year's K trade fair in Düsseldorf. The leading international trade fair for plastics and rubber, which takes place every three years, will open its doors from 16 - 23 October, 2019, under the motto "A world of pioneers". Around 250,000 visitors from over 150 countries are expected to visit the trade fair.

RAMPF Polymer Solutions, together with nine other companies, will be present at the joint booth of the Specialist Association Foamed Plastic and Polyurethanes (FSK). The FSK is an association of the plastics processing industry, its members include companies from more than ten countries, amongst them machine manufacturers, raw material suppliers, system houses/formulators, and processing companies from various material sectors.

Sealing systems, adhesives, heavy-duty elastomers – the RAMPF trade fair highlights

RAMPF Polymer Solutions is a leading developer and manufacturer of customized reactive plastic systems based on polyurethane, epoxy, and silicone with an encompassing product portfolio for a variety of applications. The company will present its expertise in the fields of sealing systems, adhesives, and heavy-duty elastomers (C.A.S.E.) at this year’s K trade fair.

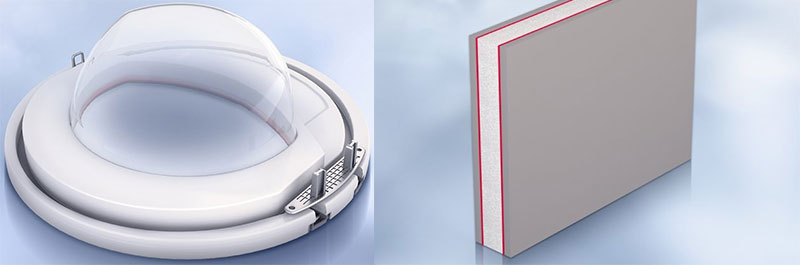

RAMPF Polymer Solutions is a specialist for liquid to highly thixotropic two-component sealing systems based on polyurethane and silicone. Especially in the automotive industry, strict emission regulations place high demands on the subcomponents used. These demands are comprehensively met by our cutting-edge sealing systems. What’s more, they also fulfil the NVH standards (Noise, Vibration, Harshness) of leading OEMs with regards to avoiding audible or perceptible vibrations in a vehicle to boost driving comfort.

The applications of sealing systems in the automotive industry include

- Door and door lock modules

- Brake lights and headlights

- Rear lights

- Electric housing

- Ignition coil covers

- Fuse boxes

- Ventilation filters

In addition to the automotive industry, RAMPF’s high-performance sealing foams are used in luminaires, control cabinets, packaging, and the household appliance industry.

RAMPF Polymer Solutions is also presenting its range of one- and two-component polyurethane adhesives, two-component epoxy adhesives, and reactive hot melt adhesives.

Bonding is regarded as the key technology of the 21st century, as it has clear advantages over other joining processes. However, the requirements for industrial adhesives are high – perfect adhesion and flexibility at the same time, high temperature and chemical resistance as well as high mechanical resistance.

The adhesives of the RAKU® PUR, RAKU® POX, and RAKU® MELT brands have already proven in numerous applications that they more than meet these requirements. Whether in the automotive sector, household appliances, sandwich elements, or assembly adhesives: Together with you we will develop the best adhesive system for your application.

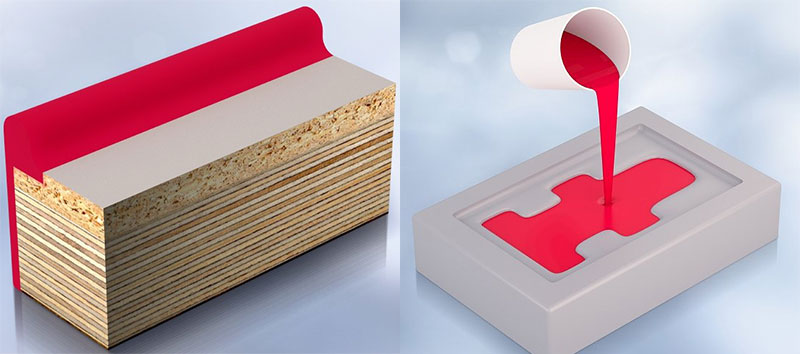

At RAMPF Polymer Solutions, C.A.S.E. stands for heavy-duty elastomers, tailor-made casting compounds, and innovative reactive resins. The customized systems of the RAKU® PUR, RAKU® POX, RAKU® SIL, and RAKU® MELT brands are used in a variety of applications:

- In the filter industry, two-component systems bond the filter end plates to the filter medium. This is where casting systems with good flowability and adhesion properties as well as high chemical resistance are required.

- Thanks to their outstanding mechanical properties, the casting systems for wetcast molds facilitate the production of molds and structures for surface replication, model (clone) production, or wet mold production.

- Doors, furniture and training carriers in hospitals, schools, kindergartens, and laboratories are protected by edge casting systems made from RAMPF construction resins. The edges of doors and furniture are permanently protected from mechanical damage, thus significantly increasing their service life.

- An efficient adhesive is required for the corner angle bonding of aluminum windows and doors. For this, RAMPF Polymer Solutions has the best product – its two-component polyurethane adhesive.