Virtual Reality at RAMPF: Stepping into the Future

The new VR room at RAMPF Production Systems in Zimmern ob Rottweil has officially been in operation since April – and it is already a real highlight for customers, visitors, and employees alike. This is where the essence of RAMPF becomes tangible: a spirit of innovation, passion for technology, and the courage to break new ground.

At the heart of the project is a dedicated three-person team that played a key role in driving the introduction of Virtual Reality (VR) at RAMPF. One of them is Daniel Grottke, who taught himself how to program – largely through self-study, often even after work hours.

“I just got hooked,” says Daniel Grottke. “When I had some free time in the evenings, I often worked on it voluntarily – not because I had to, but because I was genuinely interested.”

The idea to introduce VR at RAMPF came from within the team – and met immediate support from CEO Albert Schmid. “It was amazing to see how excited he was about our vision – that really motivated us,” recalls Daniel. The fact that company leadership backs such innovative projects shows a distinct forward-looking mindset.

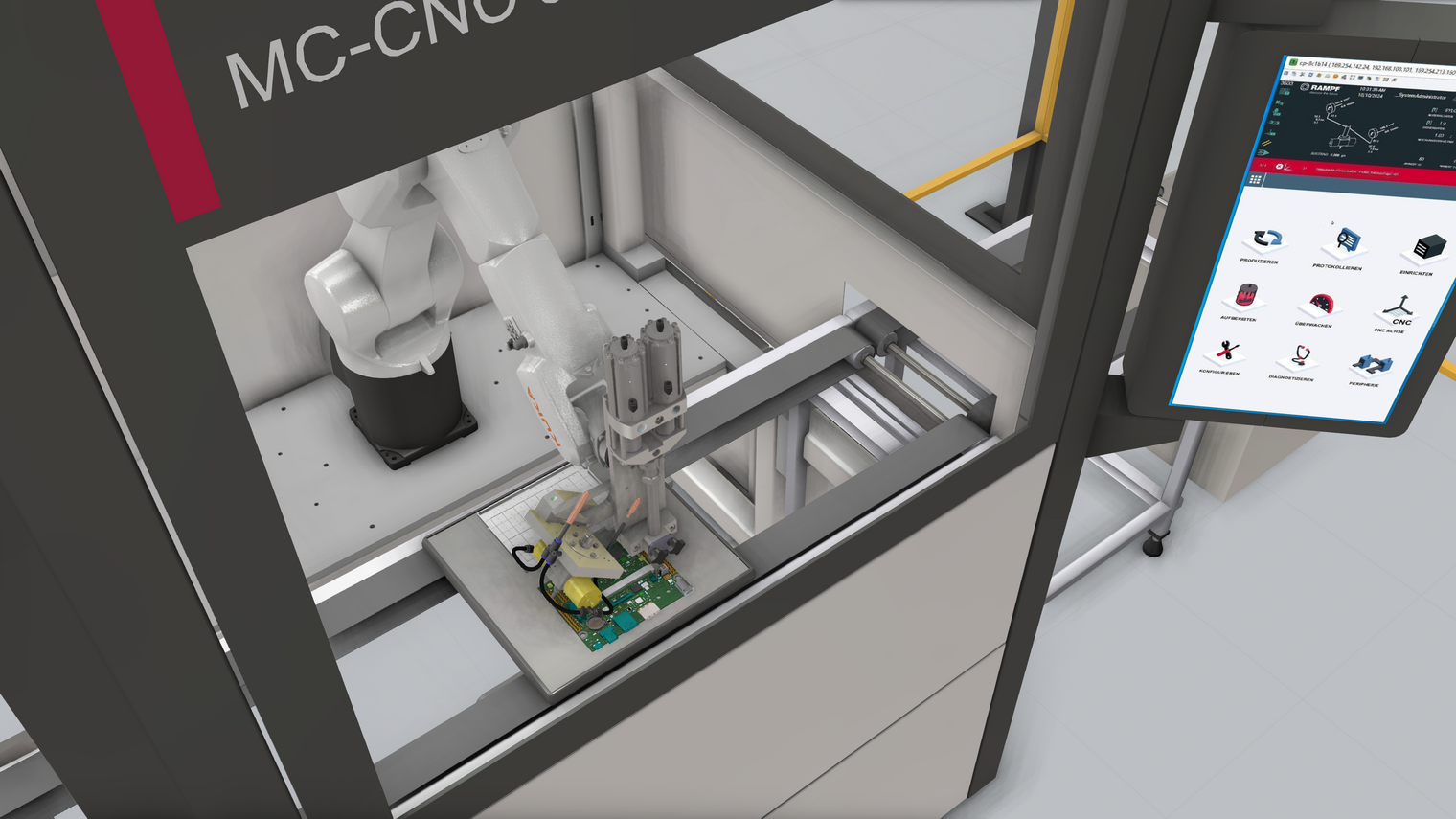

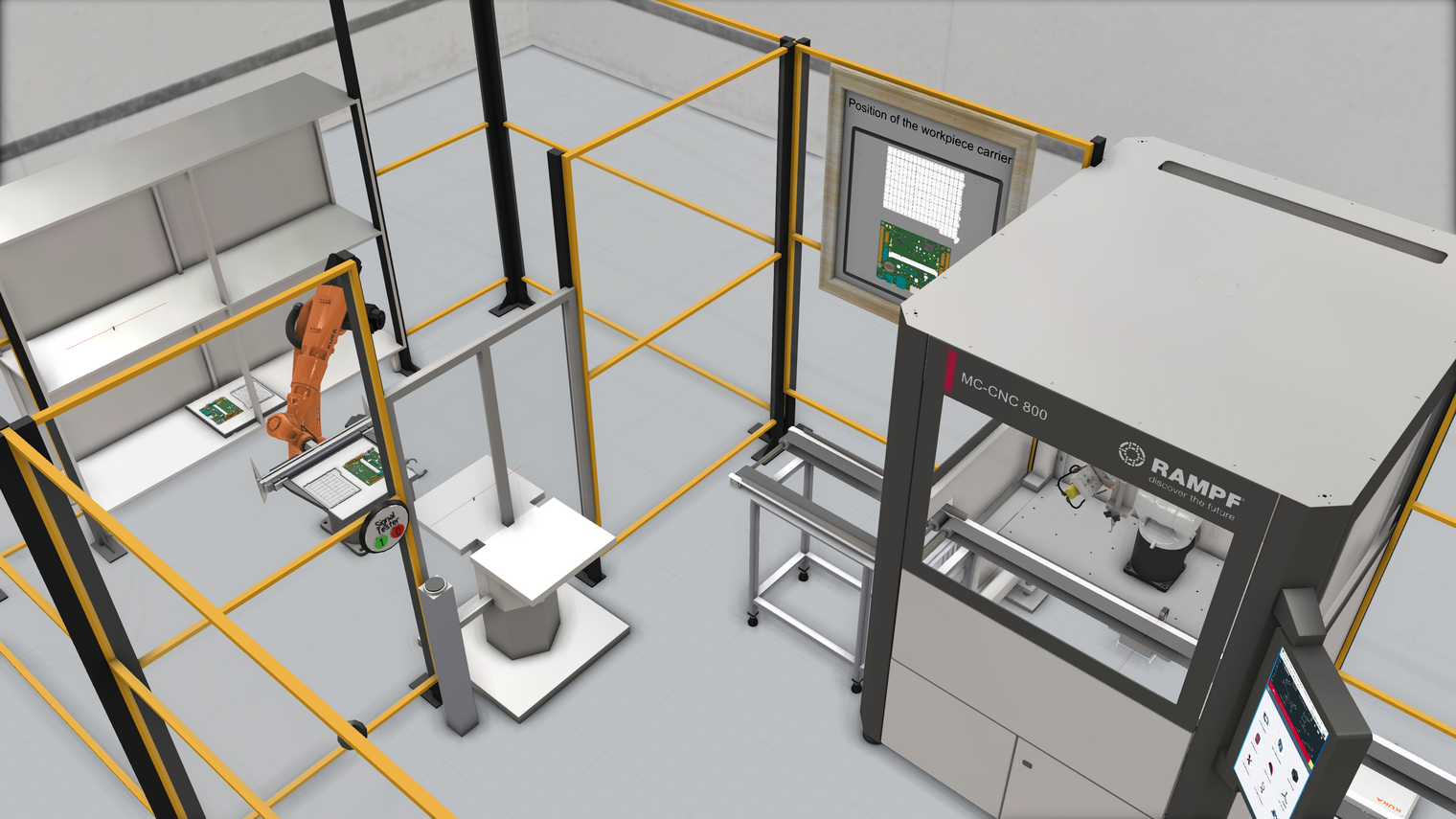

What started as a small idea thus quickly became reality. Using the software Visual Components, digital twins – virtual replicas of real machines – can now be created. These can be experienced in stunning detail in the specially designed VR room.

Space for New Perspectives

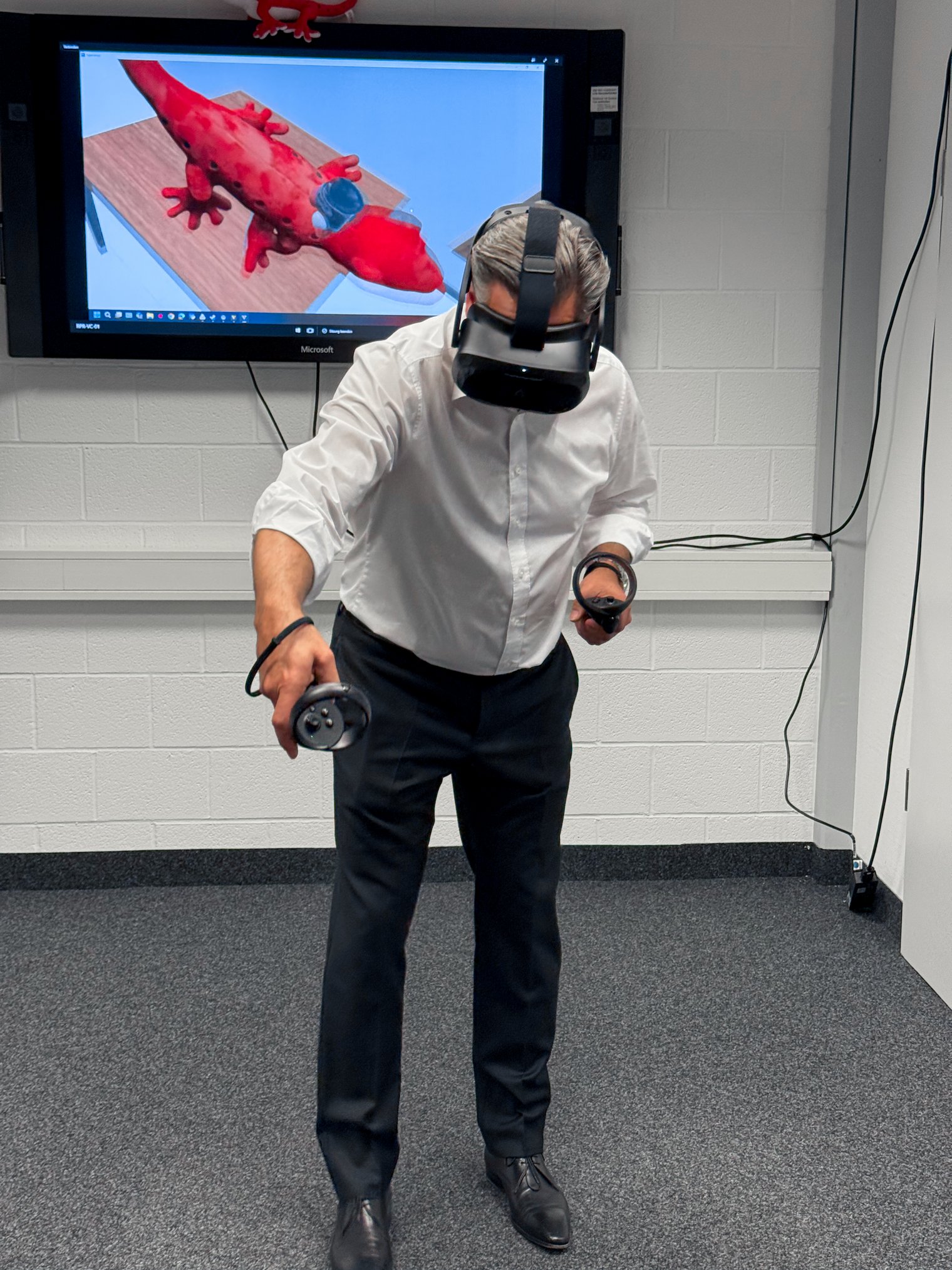

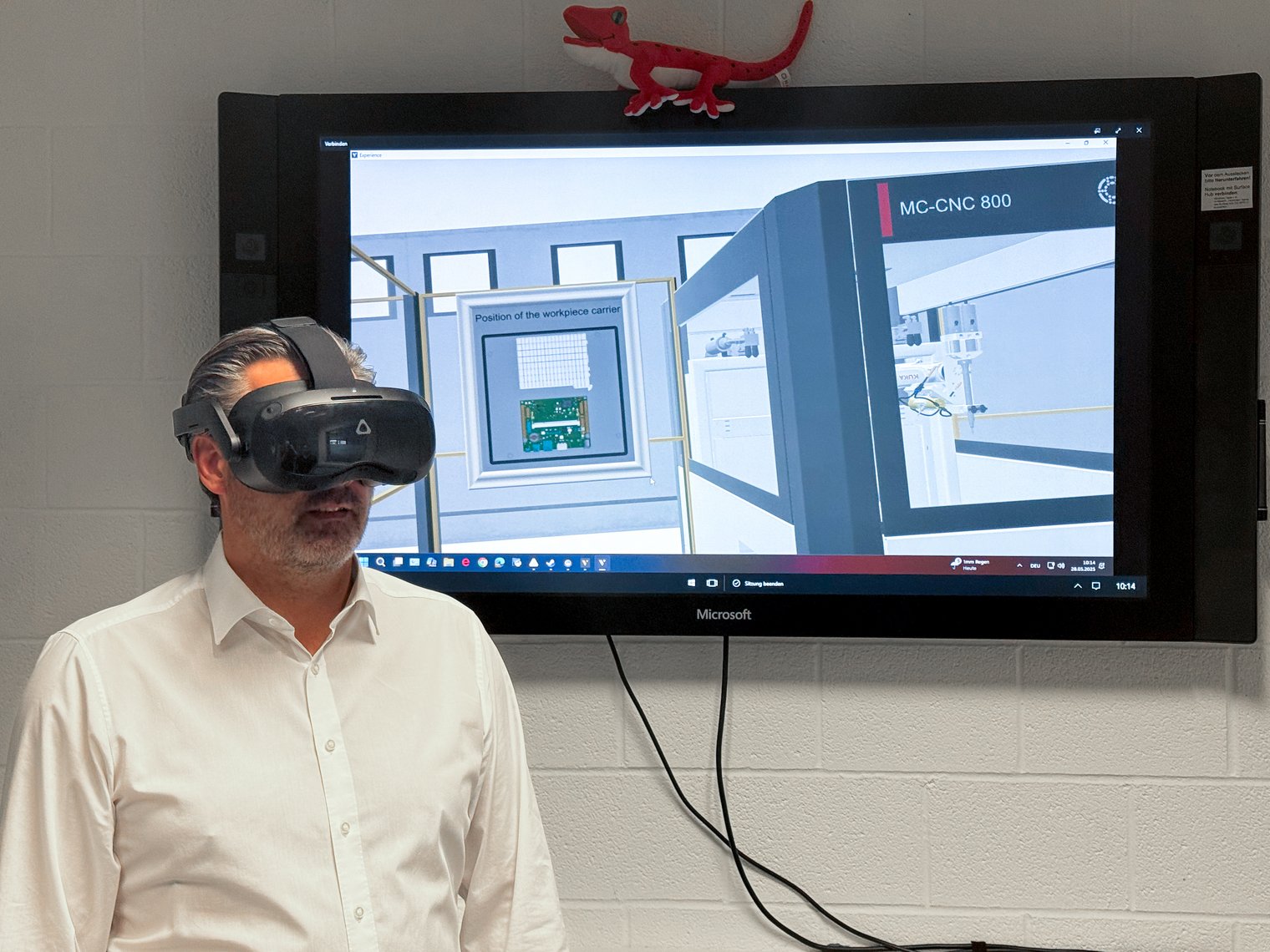

Equipped with modern VR hardware, beanbags, and a TV screen, the room offers an immersive experience. Visitors can stroll through the virtual RAMPF lobby, explore interactive applications – or even “touch” the company’s mascot Beppo, a red gecko. This is made possible through a combination of Python scripting and VR headset sensors that track hand movements and project them into the virtual environment.

One standout feature: two complete RAMPF standard systems have already been implemented in VR. This means customers can explore full-size versions of these systems – even before construction begins. The sales team can present machine concepts before a single physical component is built. Dimensions, ergonomics, and technical details become directly experienceable – perfect for customer discussions or internal planning sessions.

Teamwork & Tinkering Spirit

The project was realized independently – alongside the regular day-to-day work. Daniel Grottke handled the technical implementation, while his colleagues Tobias Atzberger and team leader Erik Beckmann made equally important contributions. Intern Ramona Müller also played a key role by preparing 3D models – also self-taught. The VR room is the result of true team spirit and a healthy dose of pioneering mentality.

A crucial factor in the project's success was the close collaboration with software provider Visual Components. The company supported RAMPF not only with excellent customer service but also offered consulting – almost like a project partner. The collaboration was so successful that Visual Components will feature RAMPF’s VR room as an official reference project on its website.

In Germany, only a few companies use the software as extensively and practically with interactive models, virtual showrooms, and real-world application scenarios for customers and sales. That RAMPF now serves as a best-practice example reflects the project's high level of development.

Enthusiasm All Around

CEO Michael Rampf also made sure to experience the new VR room in person – and was visibly impressed. What was supposed to be a short visit turned into a much longer stay. “He didn’t want to leave,” says Daniel Grottke with a smile.

“It was only my second time ever wearing a VR headset,” Michael Rampf recalls.

I was absolutely amazed by how real it feels to move among the machines and experience the production process. At one point, I got a bit too close to a robot and instinctively stepped back from the rotating robotic arm – it felt so realistic. You almost feel like you're on the Starship Enterprise when you ‘beam’ from one spot to another with a push of a button.

What moved him most, Michael Rampf adds, was thinking about the company’s development: “It was so fascinating that I found it hard to tear myself away – and I made a firm decision to come back with my father and my son. I want my father to see how far the technology has come since he took over KL-Dosiertechnik in 2003 – and my son is already a huge computer fan who even learned Python programming during his internship at an AI robotics company.”

What’s Next?

The plans are ambitious: Sales staff are expected to be equipped with mobile VR headsets, allowing them to bring the virtual RAMPF world directly to customers. This is made possible by standalone models: completely wireless, battery-powered VR headsets that require no external PC – content is simply loaded via Wi-Fi. This compact and flexible technology opens the door to using VR in the field.

There’s also strong potential for internal and external training sessions – such as safety or technical procedures. Long-term, even REFA studies (for optimizing work processes) could be conducted using body tracking to further improve ergonomic workflows.

With the new VR room, the team around Daniel Grottke once again proves how much pioneering spirit and passion are embedded in RAMPF – our employees are the driving force behind the company’s progress. We look forward to unlocking the full potential of Virtual Reality and exploring new paths together with our customers and team.