Small Size. Maximum Precision. Double Dose of Modeling Expertise!

Model railways and model making belong together. It is therefore no surprise that two market leaders, Gebr. Märklin & Cie. GmbH and RAMPF Tooling Solutions, successfully worked together on a special project – the prototype of a legendary bus draisine.

Innovation and pioneering spirit are just as much at home in Swabia as precision, finesse, and attention to detail. So, what happens when two modeling experts from southwestern Germany, in which these qualities are equally inherent, decide to work together?

Let’s find out – Gebr. Märklin & Cie. GmbH, based in Göppingen, Germany, and RAMPF Tooling Solutions have produced a 1:32 prototype of an iconic bus draisine.

A bus on rails? Yes, the bus draisine!

The bus draisine – a trolleybus with a van body – was manufactured in small numbers in Germany in the 1950s and mainly used to inspect tracks and signaling systems.

For track operation, the body of the road vehicle was mounted on a travelling model equipped with rail wheels, but without the steering wheel. A hand-operated hydraulic lifting device under the floor ensured that even a single person could lift the bus draisine, turn it, and set it back down on the tracks in the opposite direction to change the direction of travel.

Although only around seven of the specially converted vehicles are still in existence today, the bus draisine enjoys cult status among lovers of historic railways and is still used by many a railway enthusiasts' club.

Perfection and precision – thanks to RAMPF’s vacuum casting technology

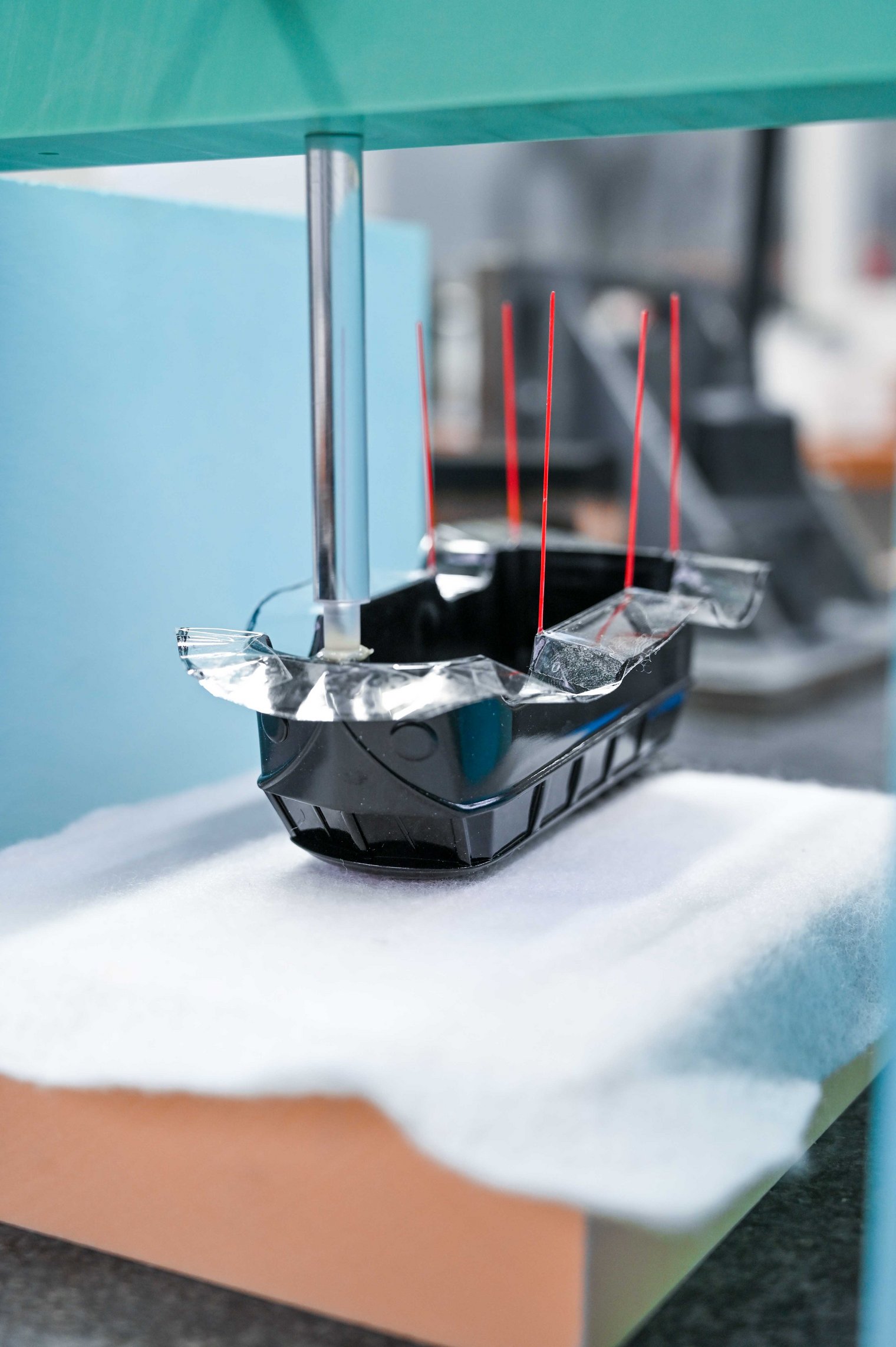

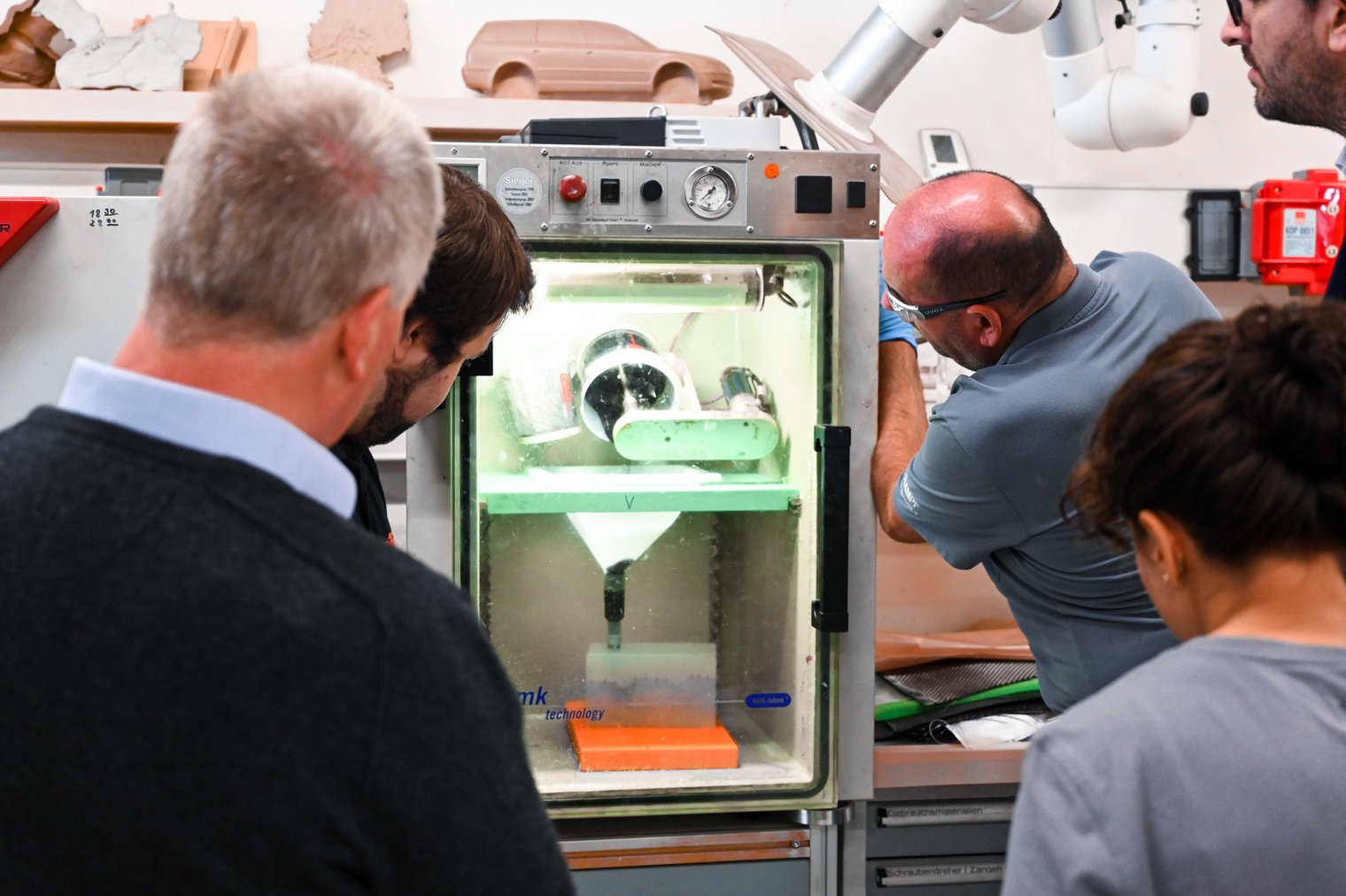

RAMPF Tooling Solutions’ model-making specialists were asked to manufacture a 1:32 model of the bus draisine – with a maximum level of detail, of course. This was achieved using the company’s innovative vacuum casting technology and vacuum casting resin RAKU® TOOL PR-3612 / PH-3920.

Thanks to its low casting viscosity, the resin system is easy to process and guarantees for precise and true-to-scale reproduction, making it ideal for prototype construction.

Next stop – the finished prototype

Based on a 3D-printed master model of the bus draisine, the RAMPF team produced a silicone mold for vacuum casting the prototype. The temperature-resistant and highly flowable material was poured into the mold, cured in the oven, demolded, and reworked.

Job done – the miniature masterpiece delighted everyone involved!

This project was like a journey through childhood memories. The bus draisine may be small, but it embodies our shared passion for creativity and innovation,

comments Marc Sarembsky, Application Technology Expert at RAMPF Tooling Solutions. Miodrag Sekulovic, Sales Manager at RAMPF Tooling Solutions, wholeheartedly agrees with his colleague,

It’s inspiring how a family outing to the Märklin Museum turned into such a great project here in Swabia.