Holistic Solutions for Electromobility – RAMPF at Battery Show Europe

The international RAMPF Group is presenting high-performance polymer systems and automated mixing and dispensing technology for fast and cost-efficient sealing, casting, and bonding of components in electromobility at Battery Show Europe in Stuttgart from June 3 to 5 – Hall 8 / Booth 8-D20.

Key Facts

- With comprehensive expertise in reactive resin systems and automated mixing and dispensing technology, RAMPF develops quality solutions that deliver maximum material performance, manufacturing efficiency, and process reliability.

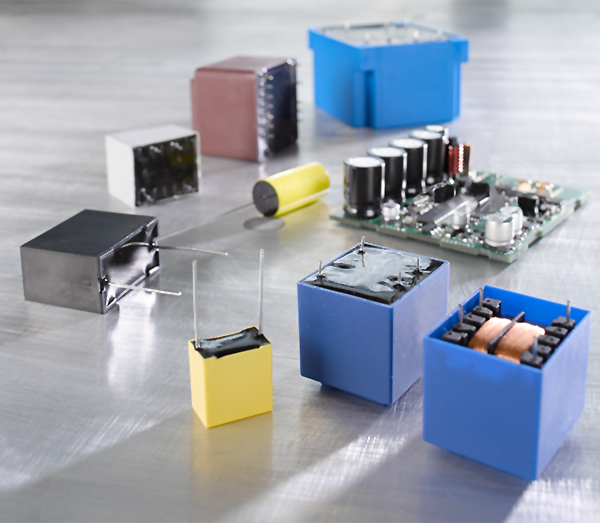

- Sealing systems, electro casting resins, and adhesives from RAMPF Advanced Polymers stand out for their exceptional chemical and mechanical properties, as well as their user-friendly processing.

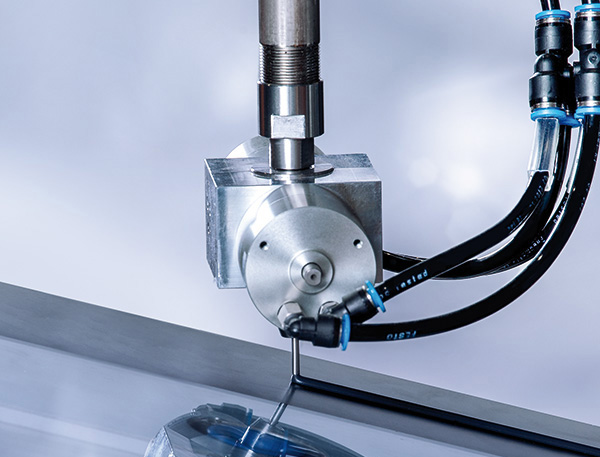

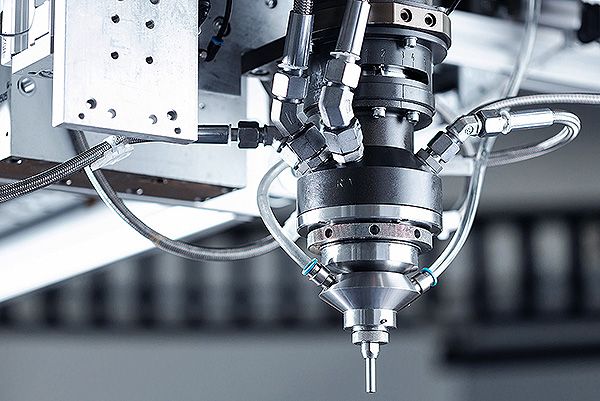

- Automated, low-maintenance mixing and dispensing technology from RAMPF Production Systems ensures precise, reliable, and cost-effective processing of single- and multi-component reactive polymer materials.

High-Performance & Versatile – Sealing Systems, Electro Casting Resins, and Adhesives from RAMPF Advanced Polymers

The material portfolio of RAMPF Advanced Polymers includes high-quality standard solutions as well as custom-developed systems with excellent mechanical, chemical, and thermal properties.

The innovative materials are listed by leading manufacturers in the automotive and electronics industries and meet international standards such as UL 50, UL 94, and RTI.

With intelligent mixing and dispensing technology and customized automation concepts, RAMPF Production Systems develops holistic solutions for its customers’ electromobility productions. A particular strength lies in its broad portfolio for processing single- and multi-component reactive polymer materials – the company has already developed more than 3,300 system solutions worldwide, ranging from simple manual systems to fully automated production lines.

The modular systems include, among other things, robot integration, component handling, material pre-treatment, heat treatment, and optical quality control. Manufacturing efficiency and reliability are significantly increased via digital process simulation, 3D system planning, and predictive maintenance.

Highly complex systems for demanding applications in electromobility

For leading OEMs and suppliers, RAMPF Production Systems designs and manufactures highly complex systems with integrated dynamic and static mixing technology – individually tailored to demanding applications in electromobility:

- Sealing of battery housings – Precise application of sealing beads on covers and housings for reliable, long-lasting sealing.

- Bonding of battery housings – Structural bonding with integrated surface activation for controlled adhesion, supported by high-precision joining tools.

- Gap filler casting – Reliable processing of highly filled, abrasive materials under atmospheric conditions for effective heat dissipation and high mechanical stability

Local Presence – Across the Globe

With production facilities, laboratory and application technology infrastructure in Europe, Asia, and North America, the international RAMPF Group delivers global service with rapid response times. Development, testing, and technical support are provided directly on-site. Customers benefit from tailored consulting, comprehensive material and process testing, and close collaboration throughout every project phase – from the initial concept to full-scale production.