Masterpieces in miniature format!

With RAKU® TOOL PR-3612 / PH-3920!

Tiny Worlds: Masterpieces in miniature format!

Speed and precision: Our material helps miniatures to make a big impact!

Details are important because all models must be very accurate. In railway and automotive model construction, it is ultimately about faithfully recreating the world of rail transport and road vehicles to scale.

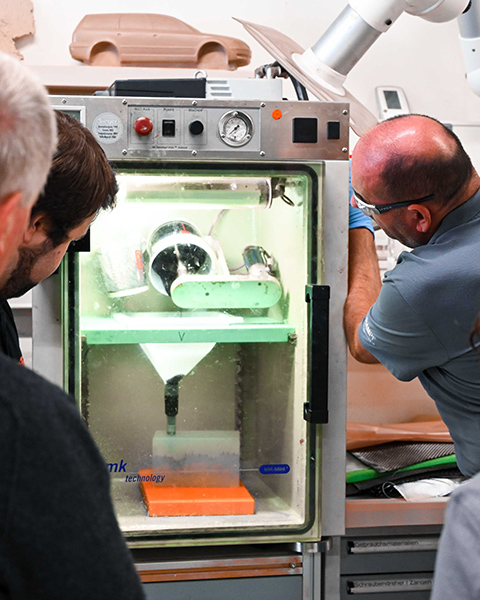

That's exactly what vacuum casting technology and our vacuum casting resin RAKU® TOOL PR-3612 / PH-3920 enable. In this way high-quality models can be produced quickly and cost-effectively.

We are particularly proud to have collaborated in the production of a bus-draisine with a true toy icon company – Gebr. Märklin & Cie GmbH!

Application

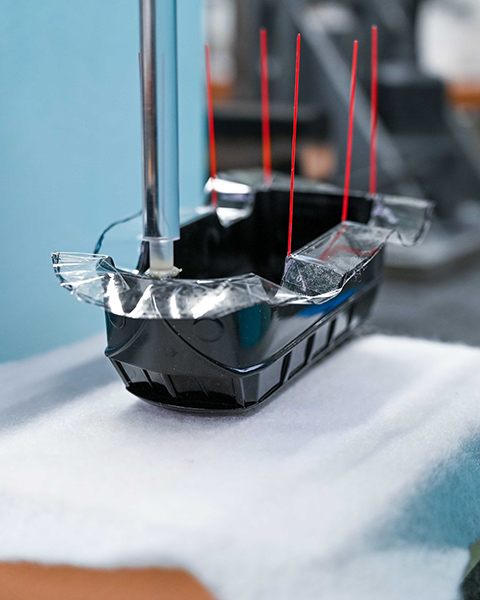

Production of prototypes for true-to-scale miniature models of a bus draisine on a scale of 1:32.

The benchmark for Märklin products is a replica of reality that is as faithful as possible - both in technical terms as well as the look and feel of the models.

Requirements for the vacuum casting resin PR-3612 / PH-3920:

- Low viscosity for easy processing and detailed reproduction of the model

- Short curing time to increase production efficiency

- Dimensional accuracy

Further applications

- Prototype functional parts

- Pilot runs / small series

- Rapid prototyping

- Spare Parts

Added Value

- Straightforward to process due to easy pre-evacuation of the individual components and low casting viscosity

- Excellent flow properties

- Imitates PP / ABS

- High impact and flexural strength

- High temperature resistance 135 °C

- Good compatibility with silicone, good service life of silicone molds