RAKU® TOOL: Materials for woodworking!

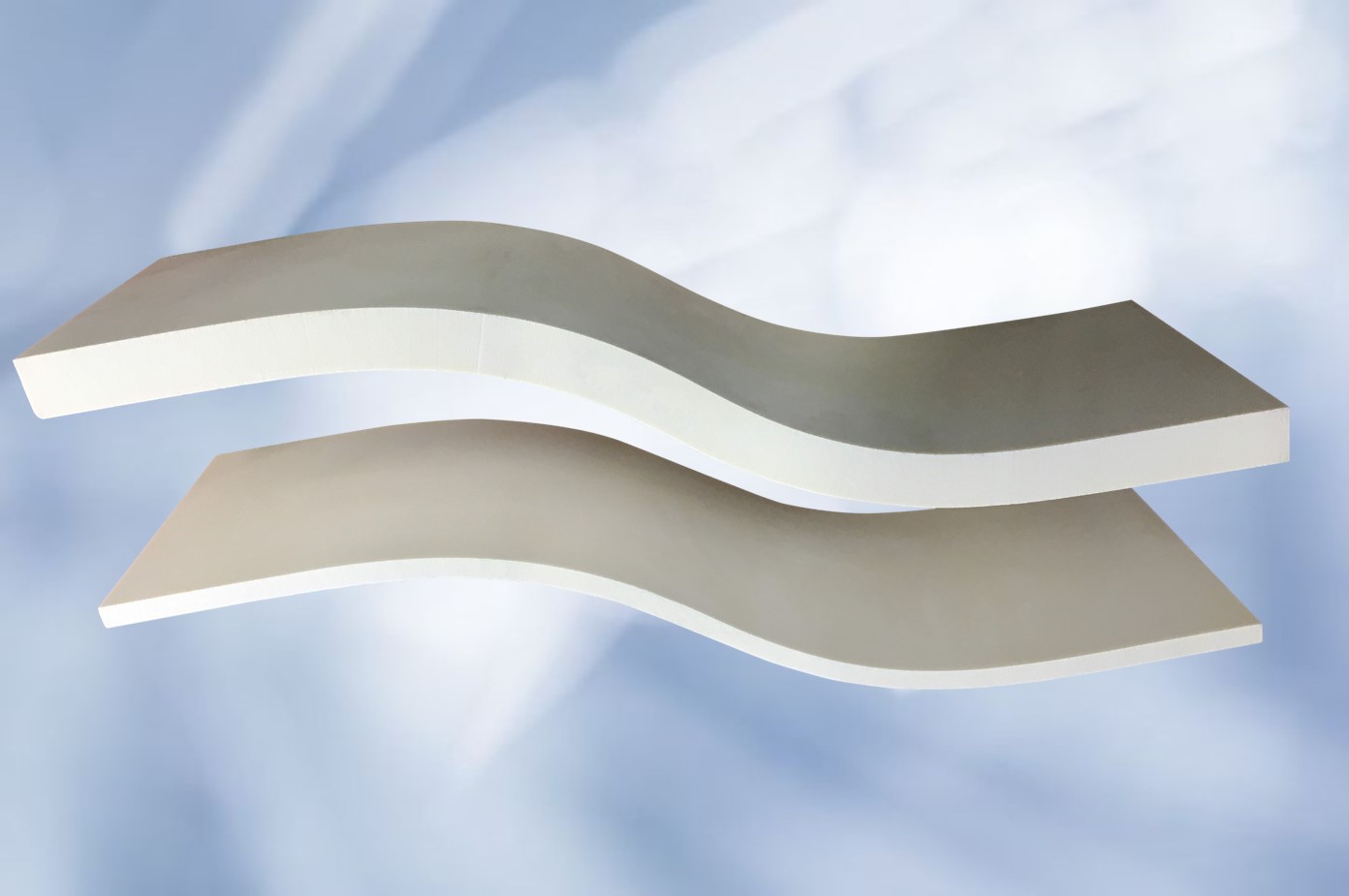

Panel materials

When classic wood reaches its limits, RAKU® TOOL panel materials offer woodworking an attractive alternative.

The panels are “Made in Germany” at RAMPF’s Grafenberg site. The RAKU® TOOL portfolio offers a vast selection of properties for numerous applications in the woodworking industry.

Polyurethane (PUR) is the basis of our panel materials. This highly versatile polymer enables us to develop products with a great variety of properties and to manufacture these with a uniform, high quality.

Applications

- Bathroom and wet areas

- Outdoor: garden, decking, fences, and privacy screens

- Buildings, facades, and cornices

- Window and door construction

- Interior work, wall and ceiling cladding

- Handrails, sectional strips, end strips, skirting boards

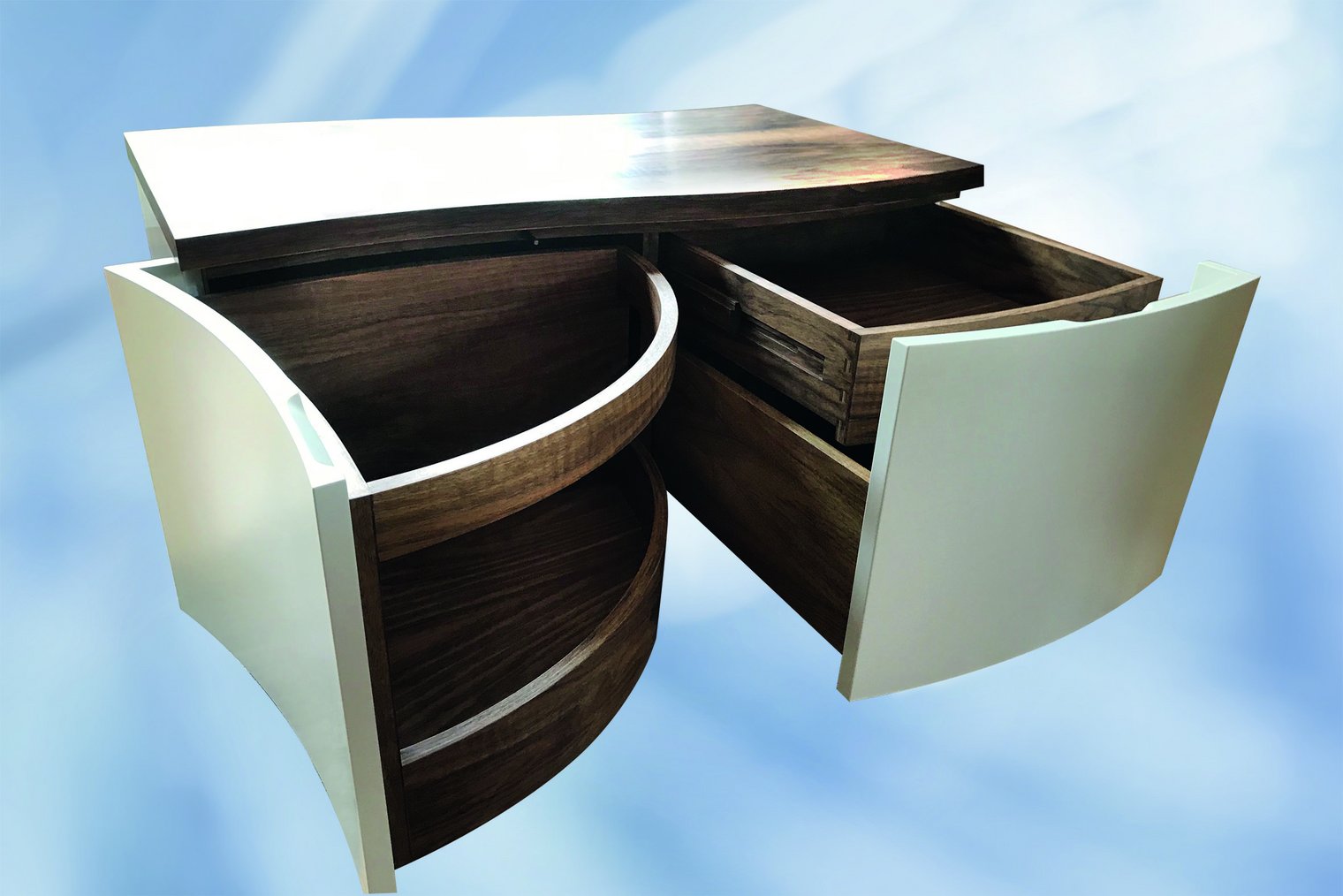

- Furniture

- Design objects

- Yachts and shipbuilding

- Interior fittings for railway and aviation

- Caravans, campers, and motorhomes

Advantages

- 100 % moisture resistant

- No swelling, rotting, warping

- No splinters or cracks

- Resistant to fungal and insect attack

- Flame retardant (fire protection classification C-s2, d0.13501-1)

- Very easy to process manually and by machine, also with conventional wood-working tools

- Various surface finishes: very good paintability, applying of precious wood or laminate veneers, imprinting, and foiling

- Easy to insert screws and nails: threads and fittings can be inserted directly

- Thermoformable; significant material savings for curved geometries

- Large selection of material properties such as density (volumetric weight), hardness, mechanical properties

- Consistent high quality with outstanding mechanical stability

- Quick availability, no tree is felled

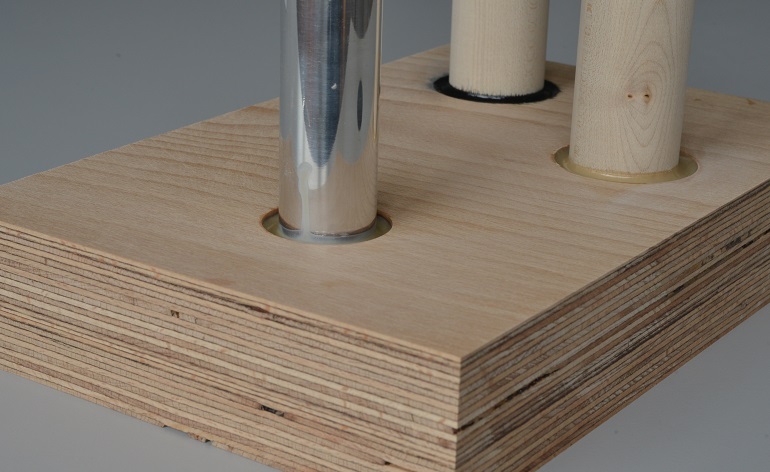

Synthetic resins

RAKU® TOOL synthetic resin systems are used in the woodworking industry to supplement and assist repairs, bonding, fixing, protecting, etc. Processing as well as grinding, polishing, drilling, and sawing are very similar to wood.

The systems are based on polyurethane or epoxy resin and exhibit an extraordinary variety of properties. They offer a quick and convenient solution for numerous tasks and applications.

- Clear Cast, Fast cast , Repair and modeling paste (flame protection)

- Various casting resins (for large volumes, high pressure loads, abrasion resistance)

- Soft foam for upholstery

Applications

- River tables / embedding objects in clear resin

- Design elements, sculptures, and art objects

- Bonding, fixing, connecting, and integrating components

- Protection against environmental influences, moisture, impact or abrasion

- Filling of cavities, cracks, and engravings

- Repair and restoration

- Foaming of upholstery