Discover the RAKU® TOOL Composites World!

RAMPF Advanced Polymers offers a comprehensive and advanced range of products for the production of models, molds and parts.

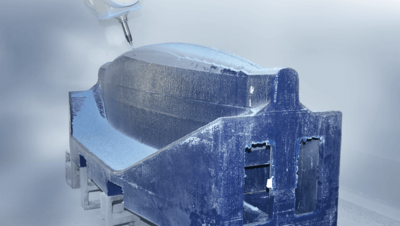

Master pattern for the production of composite parts via Resin Infusion for Full-Flight Simulator

- Fast and high-precision production of master patterns through direct milling from CAD data

- Effortless and fast milling process

- Dimensional stability: patterns crafted with stability, ensuring consistent dimensions

- High-quality surface finishes for visually appealing results after machining

- Density and hardness matched adhesives, no transfer of bonding lines to mold

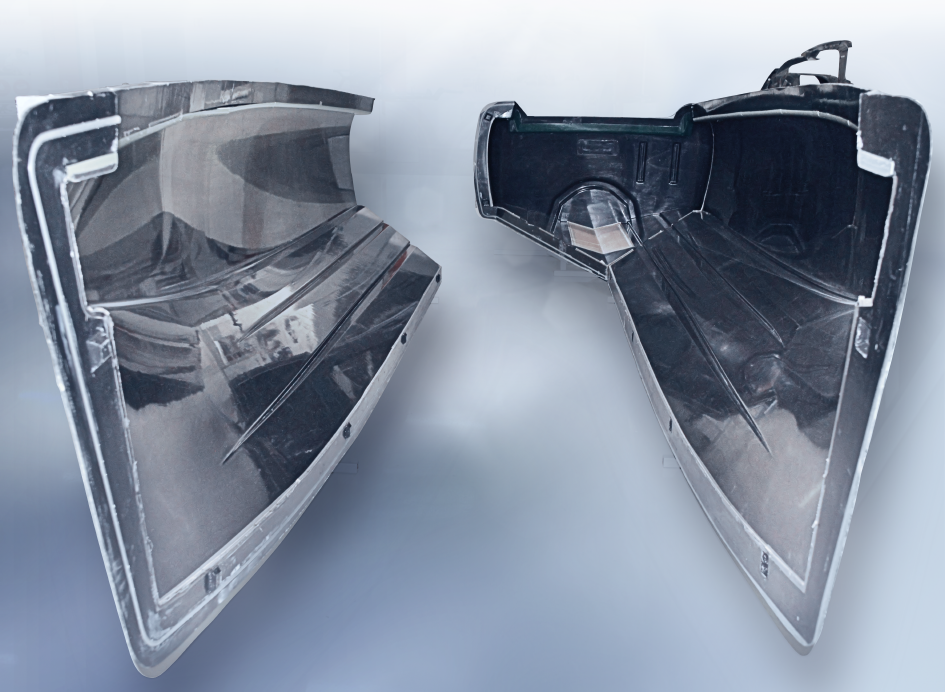

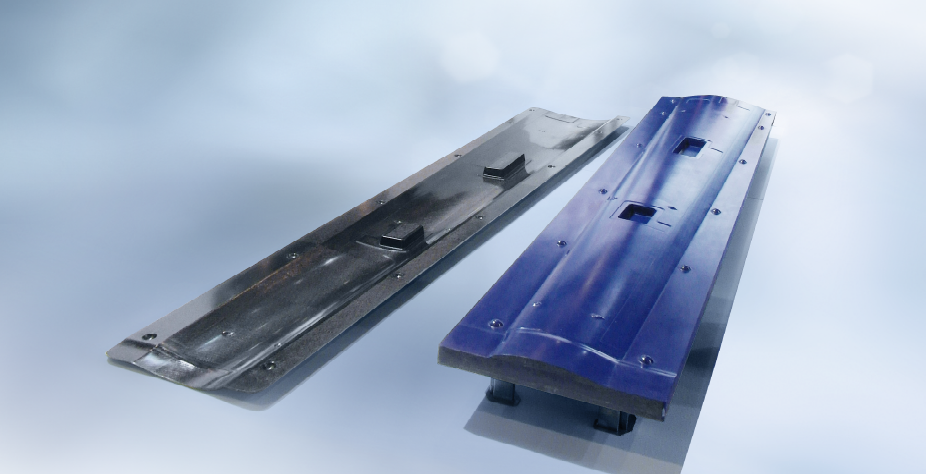

Production mold for boat hull produced via Resin Infusion

RAKU® TOOL EG-2104 / EH-2950-1 GELCOAT

RAKU® TOOL EI-2500 / EH-2973 RESIN INFUSION SYSTEM

- Large, complex molds are easy to produce via resin infusion

- Post-cure can take place at lower temperatures

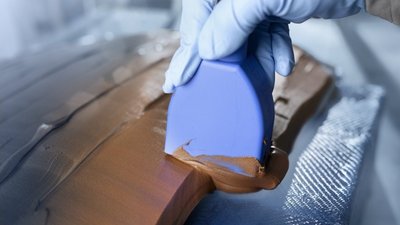

Production mold for wind turbine blades using the composite construction method

RAKU® TOOL CP-6060 CLOSE CONTOUR PASTE

- Easy to process, quick application without slump, even on vertical surfaces

- High temperature resistance of up to 70 °C

- Very fine homogeneous surface

- Good dimensional stability

- Close contour shape

- Faster milling, less waste

- Economical manufacture of large models and molds

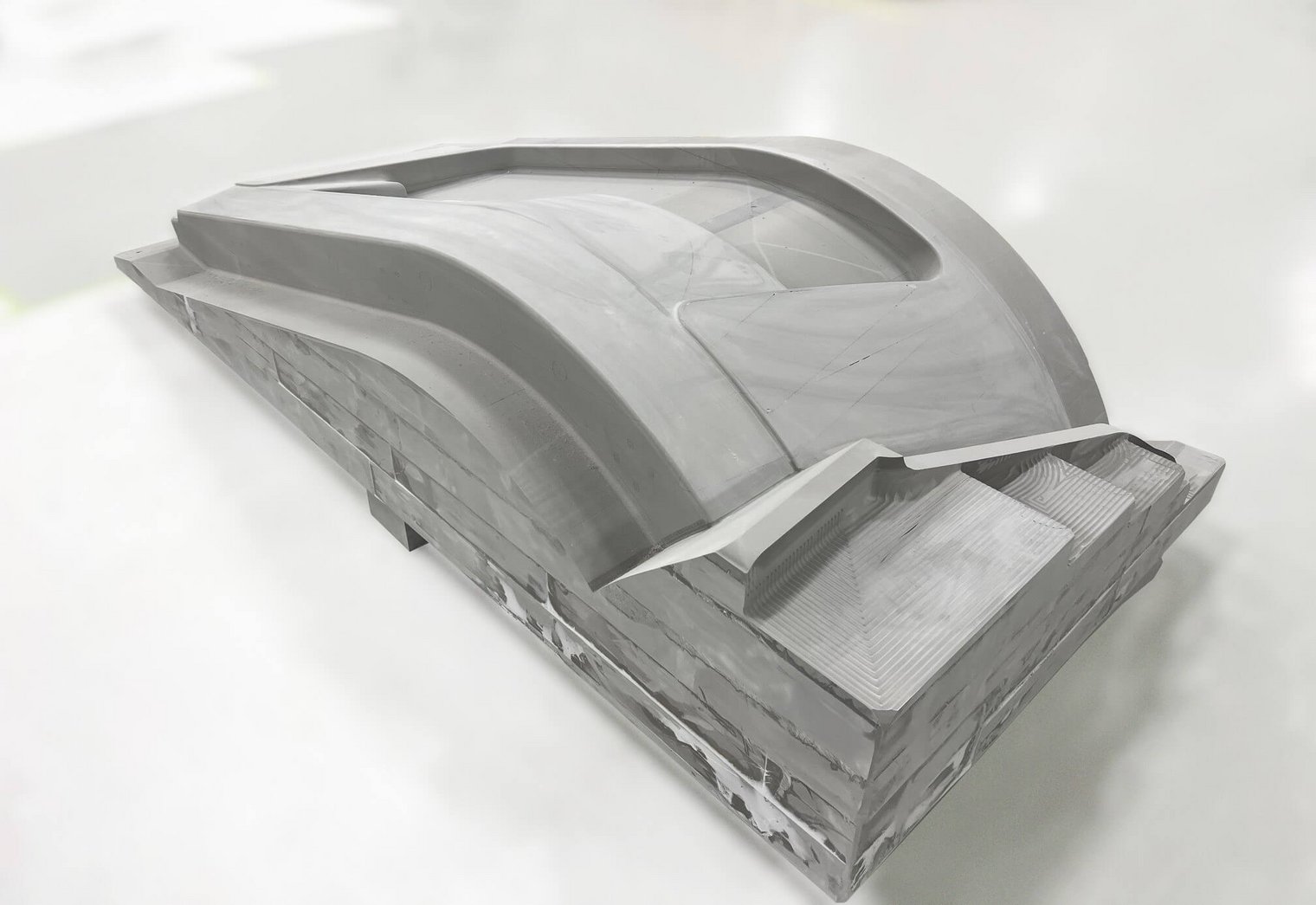

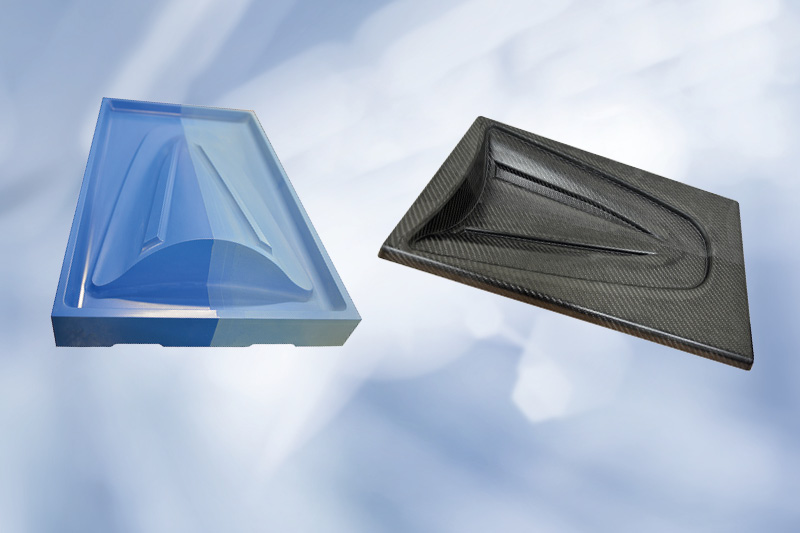

Prepreg lay-up tool

RAKU® TOOL WB-0890 BOARD MATERIAL

- Finest surface structure, less finishing time

- Significantly less sealer needed

- Surface quality finish of master model is transferred onto prepreg mold

- no re-sanding of mold necessary

- prolonged service life of prepreg molds

- HDT 100 – 110 ºC

- Dimensionally stable, excellent edge strength

- Compatible with all paints, release agents,and epoxy prepregs in line with industry standards

- Easy and quick to machine, very good chip formation, no sticking