For Reliable Bonding

Quality sticks! Whether you want to bond wood, plastic, metals. or other materials:

RAKU® PUR (polyurethane), RAKU® POX (epoxy), and RAKU® SIL (silicone) systems from RAMPF Advanced Polymers offer excellent adhesion properties for a permanently secure bond.

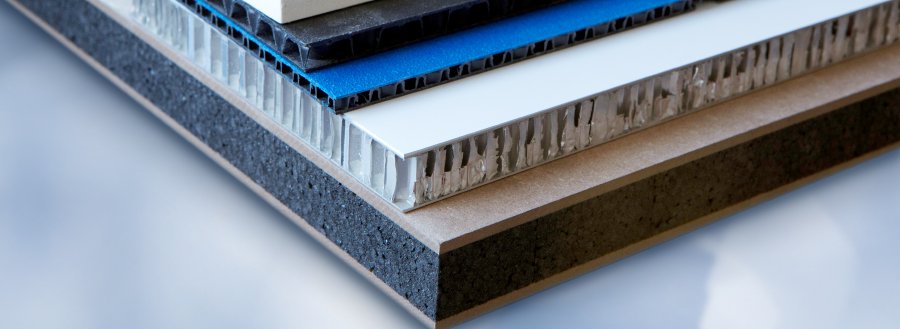

Our systems combine the ultimate in adhesion and strength with properties such as excellent temperature and chemical resistance. They can be formulated and manufactured to exhibit a wide range of properties, enabling them to be adapted to diverse requirements. They are easy to process and perform well on wood, plastic, acrylic glass, aluminum, and other mineral materials.

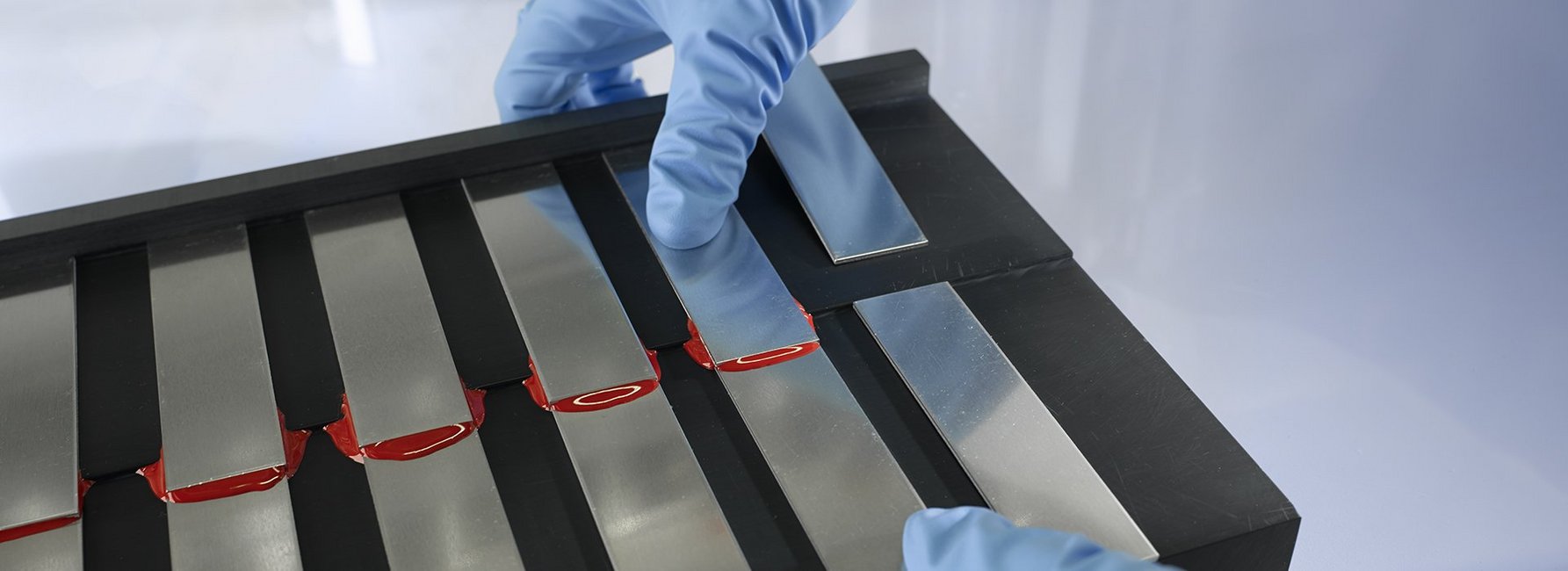

Processing takes place either manually or mechanically – using one- and two-component dispensing systems, rollers, and slotted nozzle systems.

Typical applications for our adhesives include automotive interiors, household appliances, optical bonding, the wood/furniture sector, façades, balustrades, and sandwich bonding for bus roofs, caravans, and refrigerated vehicles.

Together with RAMPF Production Systems, we offer the application expertise you need to optimize your production processes.

Material, machine, process – benefit from RAMPF’s competent complete service.

Your key benefits

- High-performance products with a wide range of properties and outstanding quality

- Customized solutions tailored to your specific needs

- Solvent- and water-free systems

- Material coordinated with your production process

- Cost savings thanks to plants that save space and energy

- Minimal cleaning to minimize maintenance

- Very user-friendly

- Excellent temperature and chemical resistance