Brand New Epoxy Board for Composite Manufacturing

At JEC World 2019, the international RAMPF Group is presenting its comprehensive product and service offering for composite manufacturing. This includes board, Close Contour, and liquid materials for modeling and mold engineering as well as composites part design, engineering, and manufacturing expertise for the aerospace and medical industries – Hall 5 / Booth P24.

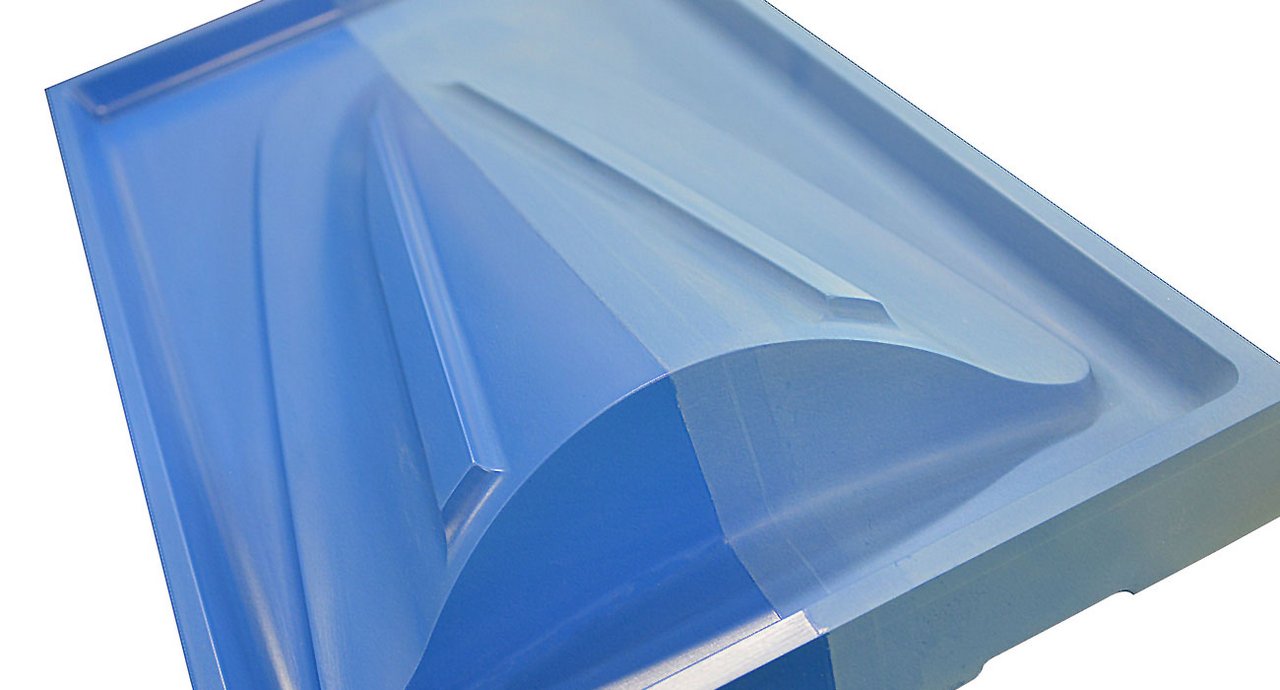

Brand New – Epoxy Board RAKU® TOOL WB-0890

RAMPF Tooling Solutions, the world's largest producer of board, Close Contour, and liquid materials for modeling and mold engineering, is presenting its new RAKU® TOOL WB-0890 epoxy board, which was specially developed for the composite industry. The board has an extremely fine surface structure, which significantly reduces both finishing and the amount of sealer that has to be used. Furthermore, the surface finish can be transferred from the master model to the prepreg mold, so that no re-sanding of the mold is required and the service life of the prepreg molds is significantly increased. RAKU® TOOL WB-0890 is easy and quick to machine and compatible with all industry-standard paints, release agents, and epoxy prepregs. Glass transition temperature Tg is 110 °C.

RAMPF Group, Inc., the US subsidiary of the international RAMPF Group and a leading expert for modeling and mold engineering materials, is highlighting two innovative epoxy systems for composite manufacturing.

The low-viscosity, low-temperature processing, and fast-curing FST system RAKU® EI-2508 is used for aircraft interiors, rail interiors, and many other applications where flame-retardant properties are required.

The high-temperature, toughened epoxy system RAKU® EI-2510 exhibits excellent hot-wet properties (dry Tg 210 °C, wet Tg 174 °C), high fracture toughness, and is used for a wide range of structural applications in high-temperature environments. The low-temperature processing 2K-system requires less investment in tooling and infrastructure and no special storage.

RAMPF Composite Solutions is highlighting its engineered solutions through innovations in advanced carbon fiber and fiberglass composites using cutting-edge technologies.

Core competencies include composite manufacturing to very tight tolerances utilizing the out-of-autoclave VARTM process, resin infusion, metal plating, and value-added assembly.

The company based in Burlington, Ontario, Canada, offers world-class engineering services for the aerospace industry, developing cutting-edge solutions from sketch to qualification.

With a team of highly qualified experts, RAMPF Composite Solutions is set up and capable to fill every role needed for demanding aerospace composites design.