Conversion of rPET & PU Wastes to Recycled Polyols

RAMPF Group, Inc. is one of the world’s leading specialists for the chemical upcycling of rPET and polyurethane (PU) wastes generated by foam manufacturers and converting these to high-quality polyols. This technology will be presented at Foam Expo North America 2022 from June 28 to June 30 in Novi, MI – Booth 1903.

The international RAMPF Group is a pioneer of PU recycling. For more than three decades, the company has been developing chemical processes whereby post-consumer PET from beverage bottles to fabrics and fibers as well as PU foam scraps from used mattresses, carpet and flooring, furniture, car seats, motorcycle seats, insulation materials, as well as fitness and leisure items are upcycled to high-quality polyols.

Using solvolysis (glycolysis, acidolysis, and aminolysis), recycled polyols are manufactured that are comparable with polyols typically obtained from virgin raw materials, both in terms of quality and technical properties. RAMPF recycled polyols are tailored precisely to the customer's production set-up and can therefore be used directly in the production of new products.

Furthermore, RAMPF has developed chemical processes that enables PET/PSA, other polyesters (PLA, PC, PHB), and renewable or bio-based raw materials such as vegetable oils to be used as sources of raw materials for the manufacture of bio-based recycled polyols.

The company also offers comprehensive advice in polyurethane recycling and developing customized polyols. The formulation of polyurethane systems using a RAMPF recycled polyol and contract manufacturing of molded components are further offerings in the portfolio.

Multifunctional recycling plants

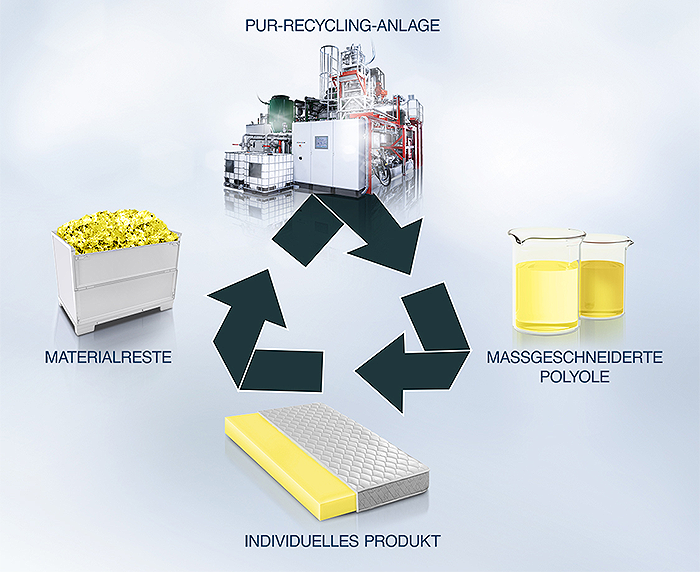

By combining its experience in chemical solutions in conjunction with the expertise of its partners in industrial plant construction, RAMPF is very successful on the international markets with a unique product offering – the development of turnkey multi-functional recycling plants for its customers.

Using their own customized plants and polyurethane waste materials, PET, phthalic anhydride, and polyisocyanurate, companies manufacture their own high-quality recycled polyols on site and use these in their production process. In doing so, they cut costs and contribute to the protection of the environment.

Dr. Shakti Mukerjee, Business Division Manager Eco Solutions at RAMPF Group, Inc.:

RAMPF chemical solutions and multi-functional plants guarantee first-class products and reduce both the dependency on volatile markets and the consumption of raw materials and energy. Our technology promotes a circular model that delivers both environmental and economic benefits. We are looking forward to presenting this unique offer at Foam Expo in Novi.