RAMPF Group

Discover the future

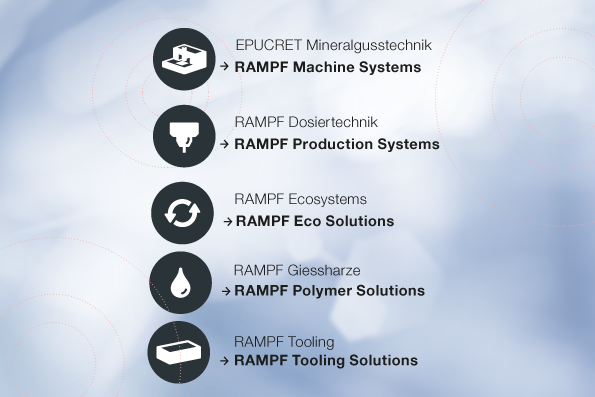

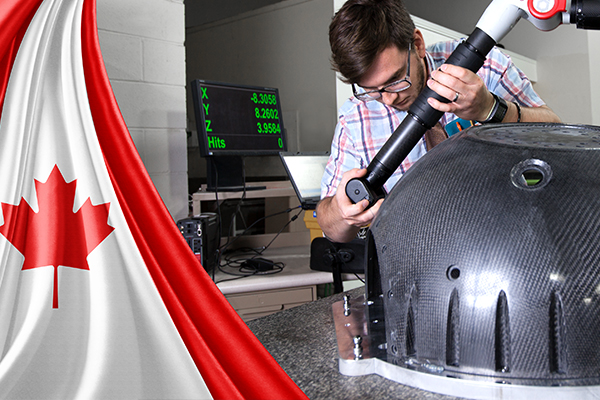

Our range of competencies includes:

- Production and recycling of materials for modeling, lightweight construction, bonding, and protection

- Technical production systems for precise, dynamic positioning and automation, as well as technologies for complex composite parts production

- Comprehensive range of solutions and services, particularly for innovative customer-specific requirements

Strong Leadership

The RAMPF Group is structured in the form of a management holding – RAMPF Holding GmbH & Co. KG based in Grafenberg, Germany – which is led by CEOs Michael Rampf (right) and Matthias Rampf (left). Horst Bader (middle) is responsible for finance and controlling.

The holding company sees itself as a service provider and strategic partner for the operating companies of the RAMPF Group. Together with the respective management teams, it is constantly generating new potential from the combination of engineering and chemical solutions and converting this into new products and solutions for customers and partners.

Protection of the environment

Environmental protection and the conservation of finite resources have played an important role at our company from day one. Rudolf Rampf set a milestone with the invention of the first polyurethane board for model making.

One aim of this development was to replace ornamental wood types such as mahogany with plastic in order to avoid further depletion of the world’s forests.

Since then, the company is constantly evaluating if technical and economic measures can be taken in the interests of environmental protection.

Commitment to sustainability

Sustainable management is a matter of course for RAMPF. As a family-run business, we pursue the goal of being economically successful and always acting in an ecologically and socially responsible manner. Bringing this claim to life is not just up to management – at RAMPF, all of us act as one.

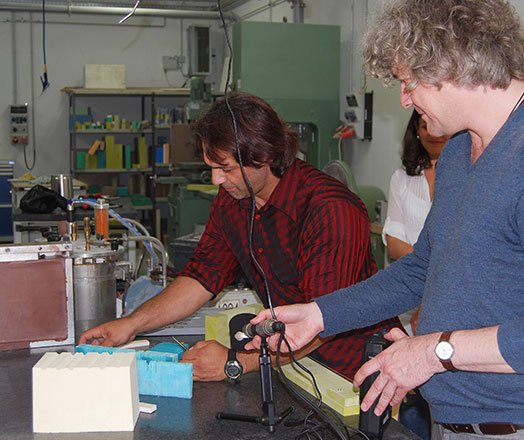

Product stewardship

Environmentally compatible product design is a mainstay of our efforts to achieve sustainability. An important aspect when developing each new product is to determine whether it can contain a certain percentage of recycled polyol.

Where economically feasible, we also consider developing a custom-made recycling polyol – depending on the anticipated annual purchase quantity.

The use of renewable raw materials is becoming increasingly important, too. Instead of looking to synthetic chemicals, preference is given to sourcing natural oils (such as castor oil) as the basis for our products.

Responsibility toward our employees

In its role as a family-run company and employer, RAMPF always strives to be a reliable partner and aims to create the best possible working conditions for employees.

Our comprehensive occupational safety concept is based on a holistic view of the work system in place that covers all the relevant technical, organizational, and HR aspects involved in optimizing safety.

Acting responsibly means taking a preventive, systematic, and comprehensive approach to all aspects of safety. This is the only way of identifying, evaluating, and eliminating risks. It involves, for example, designing fault-tolerant plant and equipment that prevent errors and minimize downtime. Safe operation of equipment at our production facilities is ensured by written instructions, training measures, and practical drills.

Rudolf Rampf Foundation

Corporate citizenship – more than just a buzzword. The RAMPF Group is well aware that a company does not operate in a vacuum and takes very seriously the need to act responsibly.

In 2001, it set up the Rudolf Rampf Foundation to support the young people of Grafenberg in their sporting, musical, and other activities. To date, the foundation has provided more than 40,000 euros of funding.

FIND OUT MORE ABOUT THE FOUNDATION